In modern metal fabrication, choosing the right welding method is essential for ensuring structural integrity, efficiency, and surface quality. Among the most widely used techniques, arc welding and laser welding offer distinct advantages depending on the application. While both methods join metals through high temperatures, their underlying principles, penetration characteristics, and surface effects differ significantly.

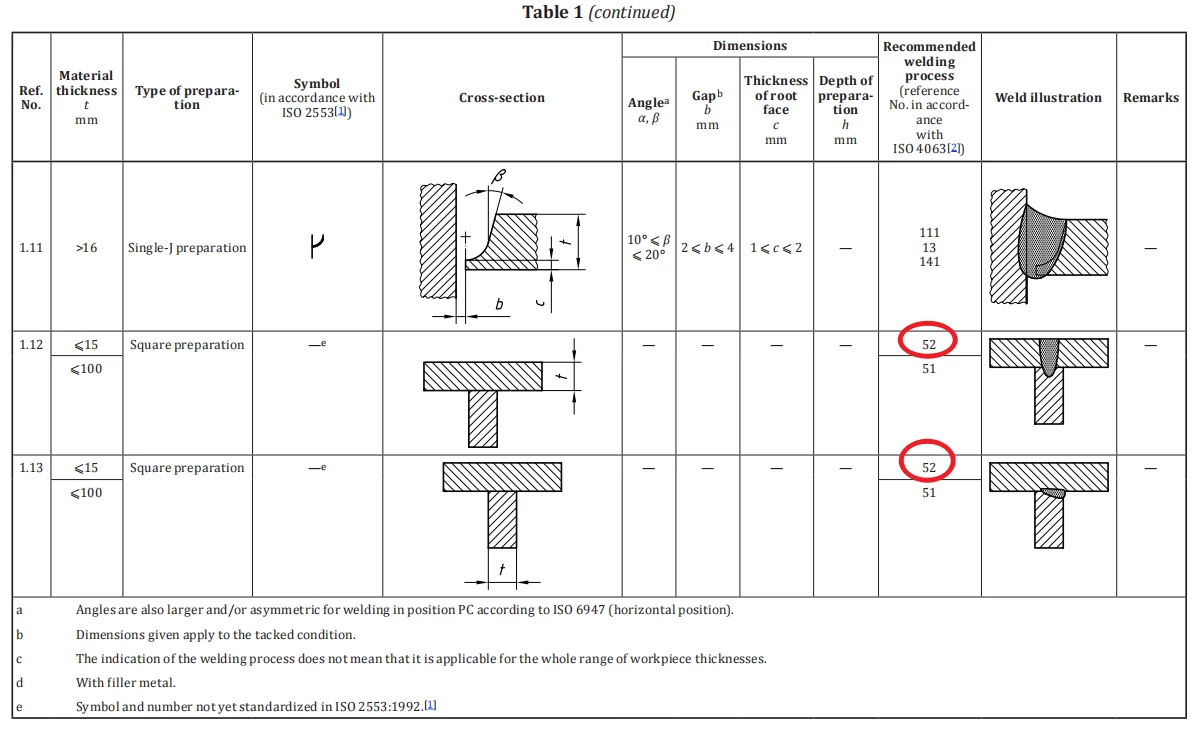

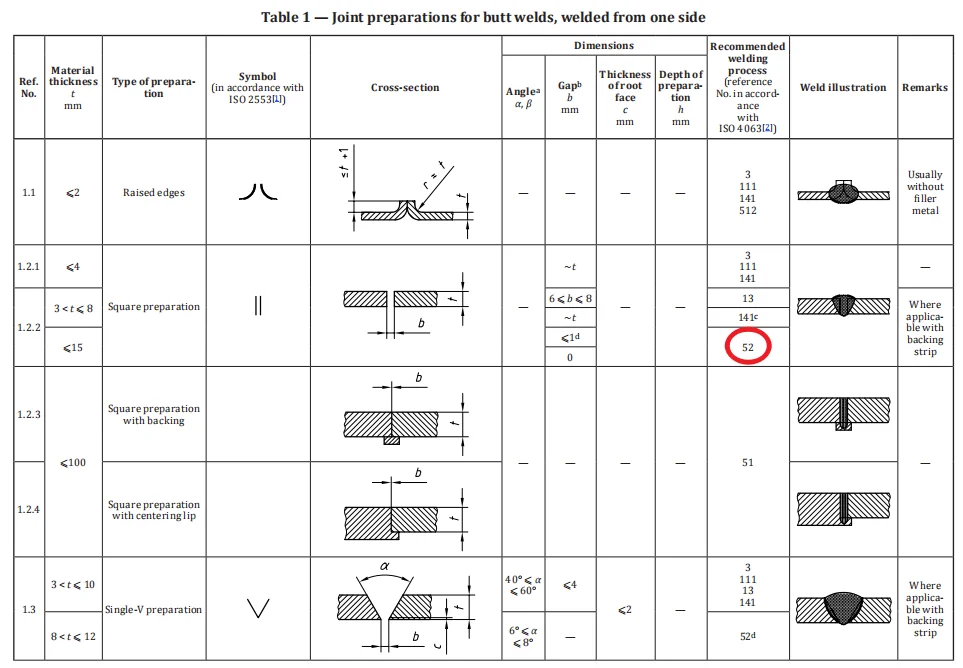

This article compares arc welding and laser welding in terms of welding morphology, oxidation behavior, and process selection logic—providing clear guidance for engineers and manufacturers. Referencing standards such as ISO 9692-1:2013, we highlight the essential differences that matter most in industrial applications—from aerospace components to stainless steel fabrication.

Essential difference:

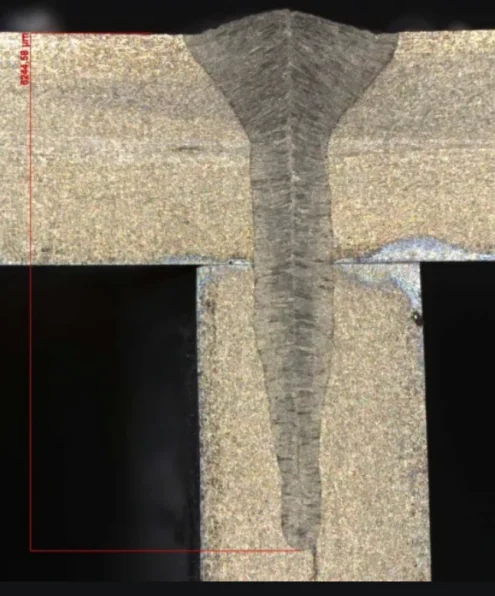

Laser welding achieves a higher penetration ratio through the “small hole effect”. refer to iso 9692-1-2013.

Fig.1 LASER welding penetration

Arc welding relies on heat conduction, and the penetration increases simultaneously with the width.

Selection Logic:

If “deep and narrow” welds are required (e.g. aerospace structural parts),LASER welding is preferred.

If “wide and shallow” welds (e.g. ordinary steel structure) are required, or if wire filling is required to enhance strength, arc welding is preferred.

Surface condition:

Surface conditions are listed below,which will largely determined what our customer concerns:

Table3.1 Characteristics on the surface

| Welding process | Weld surface morphology | Typical Cases (Stainless Steel Materials) |

| Laser welding | Narrow and flat, 0.5-2mm wide, with a mirrored or fine fish skin pattern on the surface | 1mm stainless steel plate laser welding, weld width 1mm, surface roughness Ra≤1.6μm |

| Arc welding (take argon arc welding as an example) | Wide and undulating, 3-8mm wide, with distinct large spacing | 3mm stainless steel TIG welding, weld width 5mm, surface roughness Ra≤6.3μm |

Table3.2 Oxidation on the surface

| Type of material | Oxidation of the laser welding surface | Oxidation of the arc welding surface |

| Stainless steel / Titanium | There is almost no oxidation under protective gases (such as Helium) and the surface is smooth | Cr₂O₃ blue oxide appears in poor protection |

| Aluminum alloy | It needs to be protected by high-purity argon gas, and a very thin Al₂O₃ film may remain on the surface | It is easy to form Al₂O₃ particles and needs to be mechanically cleaned |

| Copper / Brass | Laser welding has light oxidation (short energy action time), and the surface has a metallic luster | Copper is susceptible to oxidation during arc welding, and black spots of Cu₂O appear on the surface |

Conclusion

Understanding the core distinctions between arc welding and laser welding enables informed decision-making when optimizing for depth, appearance, or material sensitivity. For deep, narrow welds with minimal oxidation and precise surface finish, laser welding stands out—especially in high-performance sectors like aerospace and electronics. For broader, shallow joints or projects requiring filler wire, arc welding remains a practical and cost-effective solution.

At STRION LASER, we specialize in delivering advanced laser welding solutions tailored to your specific production needs. Whether you’re seeking fine weld seams on thin stainless steel or high-speed, low-oxidation joining for titanium and copper, STRION LASER empowers your manufacturing with precision, reliability, and innovation.

If you want to know the difference between laser welding and other welding methods, you can read the following articles: