Welding circular components is one of the most demanding tasks in metal fabrication, especially when working with aluminum. Unlike straight seams, circular joints require higher precision, stronger fixturing, and accurate control of filler wire feed. STRION LASER has conducted in-depth research on this laser welding process and shares key practices to help manufacturers improve weld quality while reducing rework rates.

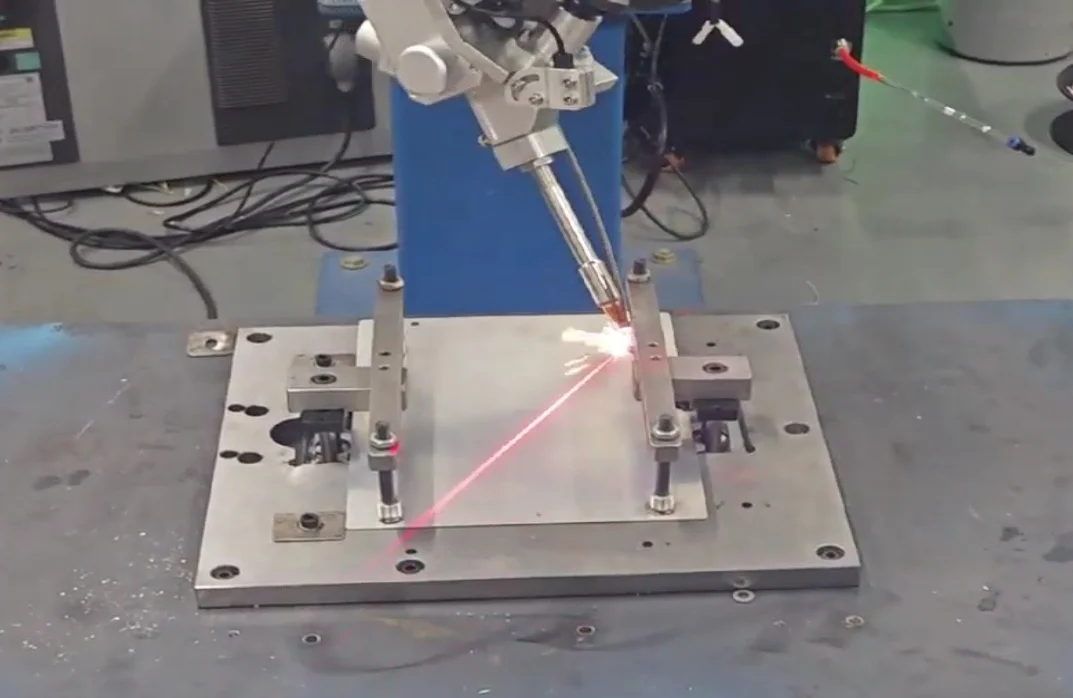

(Circular automotive parts welding)

Wire-Fed Welding vs. Autogenous Welding

Unlike autogenous welding—which fuses the joint without filler material—wire-fed welding introduces extra complexity. The filler wire constantly pushes into the molten pool, creating subtle but significant disturbances.

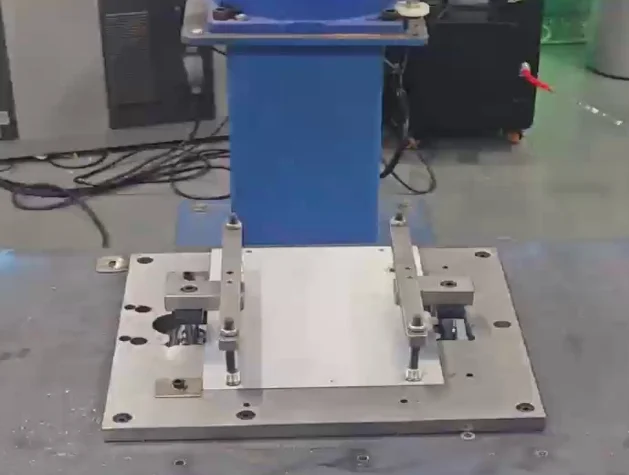

If a circular part is not firmly clamped, even the slightest vertical movement can result in uneven bead formation.

This challenge becomes even greater when performing aluminum laser welding, as aluminum’s molten pool is highly fluid. STRION LASER recommends using rigid, stable fixtures to keep circular parts completely motionless during welding. This ensures consistent penetration, smooth bead appearance, and reduces the risk of porosity or cracking.

(Stable fixtures)

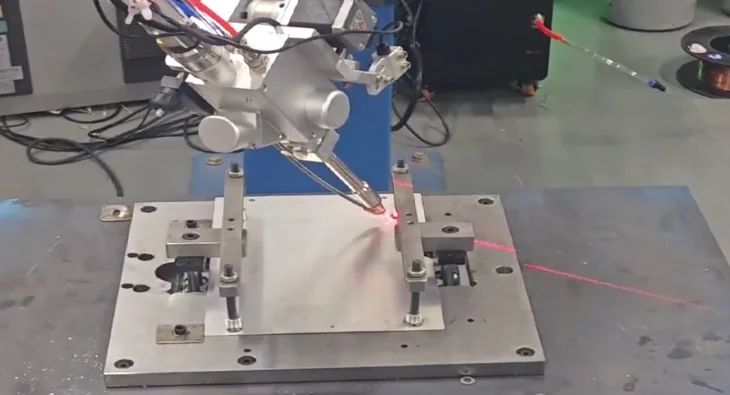

Shielding Gas Control in Aluminum Laser Welding

Shielding gas is critical in both laser welding and TIG welding as it protects the molten pool from oxidation. However, excessive gas pressure can do more harm than good.

For aluminum laser welding on circular parts, a shielding gas pressure of 0.1–0.15 MPa is recommended. Higher pressure can disturb the molten pool, creating pits or porosity along the weld seam. A balanced gas flow ensures full coverage, leading to cleaner, stronger welds with fewer surface defects.

(Shielding gas)

Positioning and Filler Wire Length Adjustment

Accurate filler wire positioning is another key factor. A proven technique in aluminum welding is to keep the filler wire slightly shorter than the red laser spot.

If the wire fully overlaps the laser beam, droplets may form on the wire tip before melting, causing an unstable bead. By shortening the wire length and aligning it precisely, welders can achieve stable melting, reduce spatter, and produce a more uniform bead profile — especially important for precision robot welding applications.

(Accurate filler wire positioning)

Conclusion

STRION LASER’s case study shows that successful circular part welding depends on three main factors:

- Rigid fixturing to eliminate part movement

- Controlled shielding gas flow to prevent molten pool turbulence

- Precise filler wire positioning for even melting and smooth bead shape

Applying these best practices enables manufacturers to achieve cleaner welds, stronger joints, and higher productivity in both aluminum laser welding and TIG welding processes. These methods also lay a solid foundation for automated robot welding systems where consistency and precision are critical.

About STRION LASER

As a leading manufacturer of advanced laser welding systems, STRION LASER delivers innovative solutions for industries that demand precision, reliability, and efficiency. From aluminum laser welding, handheld laser welding machine to fully automated robot welding lines, our technology helps companies cut costs, boost productivity, and enhance product quality.

Email: str@strlaser.com

Learn more at: www.strlaser-en.com