Metal fabrication is an essential process across many industries, from automotive to aerospace, construction, and electronics. A crucial part of this process is welding, which joins materials together using heat and pressure. Traditionally, welding methods like MIG, TIG, and stick welding have been the go-to techniques for metal fabrication. However, in recent years, handheld laser welding machines have emerged as a revolutionary alternative. In this article, we explore why handheld laser welding machines are gaining traction and how they can benefit metal fabrication processes.

What is a Handheld Laser Welding Machine?

A handheld laser welding machine is a portable, high-precision tool that uses focused laser beams to melt and join metal pieces. Unlike traditional welding methods, which use electric arcs or gas flames to heat the material, laser welding relies on concentrated light energy. The focused beam generates intense heat at a specific point, allowing for precise and efficient welding with minimal distortion.

These machines typically feature a hand-held unit, making them highly versatile and suitable for a range of applications, from large-scale production lines to small, intricate jobs. Handheld laser welders are also designed to be more user-friendly, with digital controls for easy adjustment of parameters.

Advantages of Handheld Laser Welding Machines

Handheld laser welding machines offer several key advantages over traditional welding methods, making them an increasingly popular choice in metal fabrication:

1. Precision and Quality

One of the biggest advantages of handheld laser welding is the exceptional precision it offers. The focused laser beam results in high-quality welds with minimal heat-affected zones. This is particularly important when working with sensitive materials or where aesthetic quality is critical, such as in the jewelry or electronics industries.

Laser welding also produces a cleaner weld, often requiring little to no post-weld processing, which is a significant time-saver.

2. Speed and Efficiency

Handheld laser welding machines can weld at much faster speeds compared to traditional methods, improving productivity and reducing overall project timelines. The process also generates less heat, which reduces the need for cooling, resulting in shorter cycle times.

The high speed of welding means that businesses can increase throughput, thereby enhancing overall efficiency.

3. Ease of Use

Handheld laser welding machines are designed for user-friendliness. Many models feature intuitive control systems that simplify the welding process, making it accessible even to those with limited experience. These machines are equipped with adjustable settings for power, speed, and focus, allowing welders to fine-tune their parameters for optimal results.

The portability of these machines further enhances their ease of use, making them ideal for both workshop and on-site applications.

4. Portability

The lightweight, portable design of handheld laser welders makes them suitable for welding in confined spaces or on-site jobs where traditional welding equipment might be too bulky or difficult to maneuver. This portability ensures that laser welding can be used in a wide variety of environments, from industrial plants to fieldwork locations.

Applications of Handheld Laser Welding in Metal Fabrication

Handheld laser welding machines are versatile and can be used in many industries and applications. Some notable uses include:

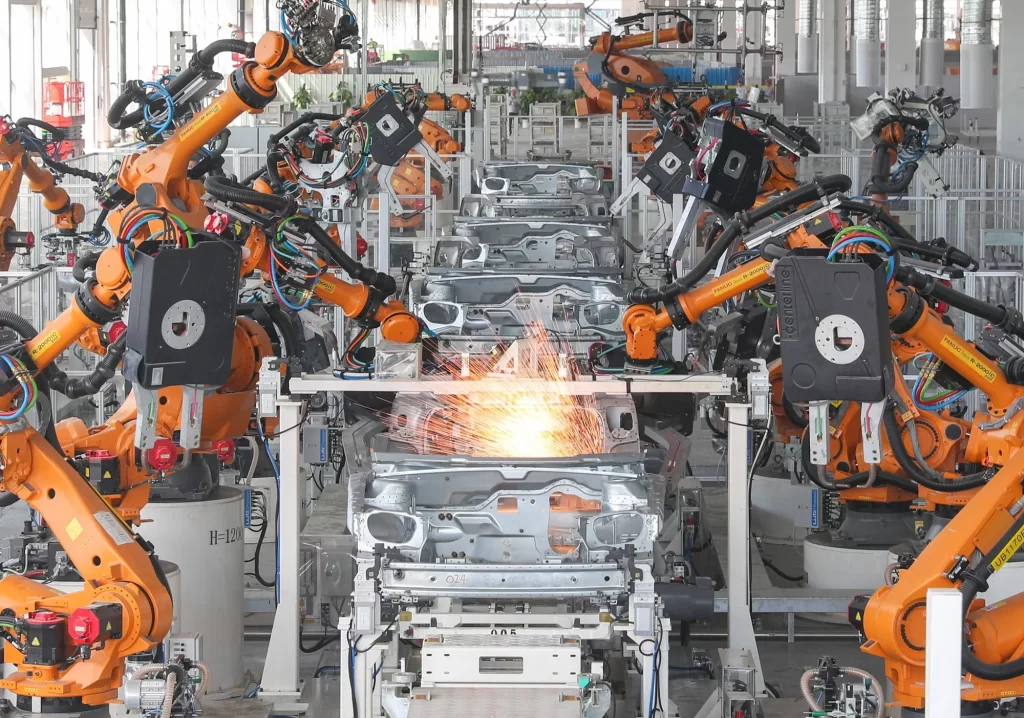

1. Automotive Industry

In the automotive sector, handheld laser welding is used for precision welding of body panels, exhaust systems, and other critical components. The accuracy and speed of laser welding ensure that automotive manufacturers can produce high-quality parts with minimal distortion.

2. Aerospace

The aerospace industry requires strong, lightweight welds that can withstand extreme conditions. Handheld laser welding machines are ideal for welding aircraft components such as engine parts, frames, and structural components, ensuring the safety and reliability of these critical parts.

3. Jewelry and Small-Scale Fabrication

Laser welding is perfect for applications where fine, intricate work is required, such as in the jewelry industry. Handheld laser welding machines can precisely join delicate materials like gold, silver, and platinum without damaging or distorting them.

4. Construction and Infrastructure

In construction, handheld laser welding is used for joining metal beams, frames, and other structures, particularly when a high degree of precision is necessary. The ability to weld on-site, even in challenging environments, adds to the versatility of handheld laser welders.

5. Electronics Manufacturing

The electronics industry often uses laser welding for micro-joining small components such as circuit boards, batteries, and connectors. The precision of the laser allows for fine, secure welds that are critical in the production of high-performance electronic devices.

6. Medical Instruments

Laser welding is ideal for welding medical instruments due to its high precision and minimal thermal impact. In medical device manufacturing, the need for clean, non-contaminated welds is critical, especially in surgical tools and implants. Laser welding enables the creation of sterile, seamless joints without introducing foreign materials that might compromise hygiene or cause infections.

Key Features to Look for in a Handheld Laser Welding Machine

When selecting a handheld laser welding machine, there are several important features to consider:

1. Power Output

The power output of the machine determines its ability to handle different materials and thicknesses. It’s important to choose a machine with adjustable power settings that can cater to a range of welding tasks.

2. Cooling Systems

Due to the high heat generated during laser welding, a robust cooling system is essential for maintaining optimal machine performance. Effective cooling helps prevent overheating and extends the lifespan of the equipment.

3. Beam Quality

The quality of the laser beam directly impacts the precision of the welds. Ensure the machine provides a stable and focused laser beam with minimal divergence to achieve high-quality results.

4. Adjustability

A key benefit of handheld laser welding machines is their versatility. Look for machines that allow for fine-tuning of parameters like speed, power, and focus to accommodate different welding tasks and materials.

Cost-Effectiveness and ROI of Handheld Laser Welding Machines

While handheld laser welding machines may have a higher initial cost compared to traditional welding methods, they offer excellent return on investment (ROI). The faster welding speeds and high precision reduce the need for post-weld processing, lowering labor and material costs. Additionally, their portability reduces the need for additional equipment or set-up time.

Over time, the enhanced efficiency, reduced operational costs, and increased productivity make handheld laser welding machines a cost-effective solution for many businesses.

Conclusion

Handheld laser welding machines offer unparalleled precision, speed, and portability, making them an ideal choice for a wide variety of metal fabrication tasks. Whether you’re working in the automotive, aerospace, jewelry, or construction industries, these machines provide a cost-effective, efficient solution for high-quality welding. While there are some challenges to consider, the benefits of handheld laser welding machines far outweigh the drawbacks, especially when factoring in long-term savings, increased productivity, and ease of use.

If you’re interested in learning more about how a handheld laser welding machine can improve your metal fabrication processes, contact Strongest Laser today for a demonstration or consultation. We’re here to help you choose the best equipment for your needs.