Welding technology has evolved significantly over the years, with new innovations transforming traditional practices. From arc welding to MIG and TIG welding, the welding industry has embraced new technologies to meet the growing demands for precision, speed, and efficiency. One such modern solution is the handheld laser welding machine, which offers a cutting-edge approach to joining materials with high accuracy and speed. This article will explore what handheld laser welding machines are, their key features, advantages, applications, applicable materials, and the future trends shaping their adoption in various industries.

1. What is a Handheld Laser Welding Machine?

A handheld laser welding machine is a portable, high-tech device that uses a focused laser beam to create a high-quality weld between two materials. Laser welding is a type of welding that utilizes the intense heat generated by a laser beam to melt and fuse materials together. The handheld design allows for greater mobility and flexibility, enabling operators to perform precise welding tasks in a variety of settings, from manufacturing plants to repair workshops.

Components and Structure of a Handheld Laser Welding Machine

The basic structure of a handheld laser welding machine includes several key components:

- Laser Source: The laser source generates the high-intensity laser beam, usually a fiber laser.

- Handheld Gun or Torch: The operator uses this to direct the laser onto the workpiece, providing the necessary control for precision welding.

- Cooling System: This keeps the laser source and other components at optimal operating temperatures to prevent overheating.

- Control System: The interface that allows operators to adjust settings such as power levels, welding speed, and other parameters.

How it Works: Basic Principles of Laser Welding

In a handheld laser welding machine, the laser beam is concentrated onto the surface of the materials to be welded. The intense heat from the beam melts the materials, which then fuse together upon cooling. This process is highly controlled, ensuring precise, clean welds with minimal distortion and a small heat-affected zone. The portability of the handheld design enables operators to perform welding on parts and structures that might be difficult to access with traditional fixed machines.

2. Key Features of Handheld Laser Welding Machines

- Portability: The compact, handheld design allows for easy maneuverability, making it suitable for welding in tight spaces or for mobile repairs. This flexibility reduces the need for large, stationary equipment.

- Precision: Laser welding technology offers unmatched accuracy, allowing operators to create fine, consistent welds with minimal heat input, reducing the chances of material distortion.

- Adjustable Power: Handheld laser welders allow operators to adjust the laser power according to the type of material and thickness, ensuring optimal welding conditions for each job.

- Speed and Efficiency: Laser welding is faster than traditional welding methods. The focused energy allows for quick melting and fusion of the material, which can significantly reduce production times and increase overall efficiency.

- Minimal Heat-Affected Zone (HAZ): The precision of the laser results in less heat spreading into the surrounding material, minimizing deformation and ensuring cleaner welds.

- Ease of Operation: Most handheld laser welding machines are user-friendly, with intuitive controls that require minimal training. This accessibility makes it easier for operators to achieve high-quality results.

3. Advantages of Handheld Laser Welding Machines

- Improved Weld Quality: Handheld laser welding machines produce clean, precise welds with little need for post-processing. The controlled heat input reduces the chances of defects such as spatter, distortion, or burn-through.

- Reduced Heat Input: The minimal heat input reduces the risk of material deformation and shrinkage, making it ideal for thin, delicate materials that would be prone to warping with conventional welding methods.

- Cost-Effective: While handheld laser welders may have a higher initial cost than traditional welding machines, the efficiency, speed, and reduced need for consumables (such as filler materials) make them more cost-effective over time.

- Flexibility: These machines can weld a wide variety of materials, including steel, aluminum, copper, and more. This makes them versatile for different industries, such as automotive, aerospace, and manufacturing. (The specific application scenarios of the handheld laser welding machine and the materials that support welding are listed separately below.)

- Environmentally Friendly: Handheld laser welding produces fewer emissions compared to traditional welding methods. The precision of the laser also minimizes waste, making it a more environmentally sustainable option.

4. Applications of Handheld Laser Welding Machines

Handheld laser welding machines are used in various industries for tasks requiring precision and efficiency. Some of the key applications include:

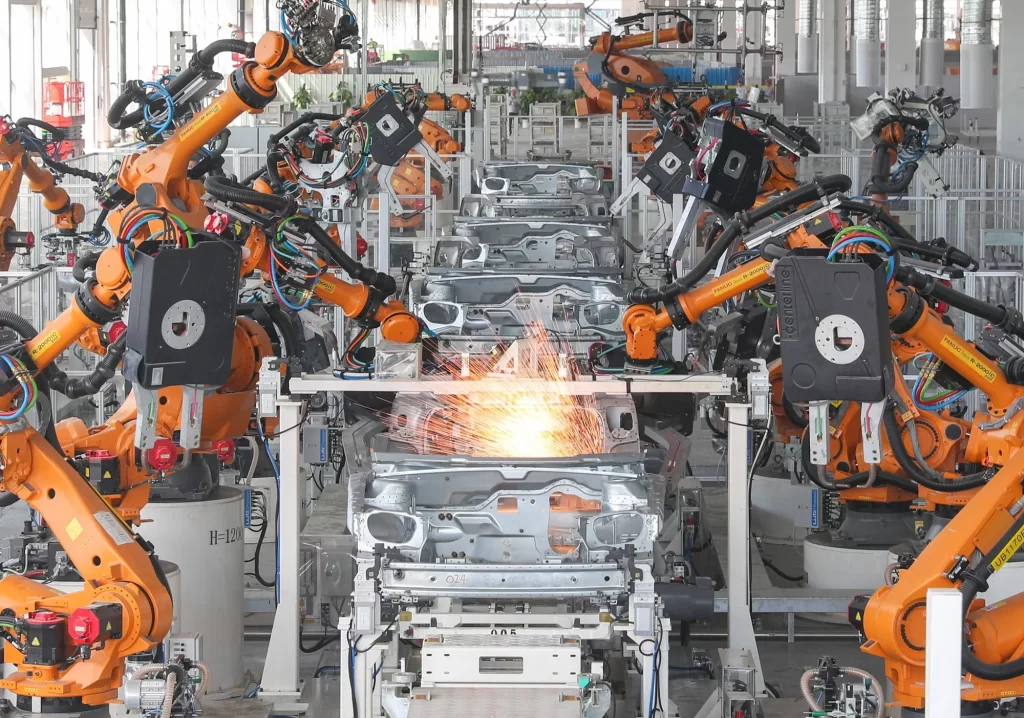

Vehicle Manufacturing:

In the automotive and rail industries, handheld laser welding is used for the body manufacturing of subway cars, high-speed rail rolling stock, and other transportation components. Laser welding is particularly beneficial in these industries for joining high-strength steel and aluminum alloys, which are commonly used in vehicle frames and structural components. The precision of laser welding ensures that the welds meet the strict safety standards required in the transportation sector.

Medical Instruments:

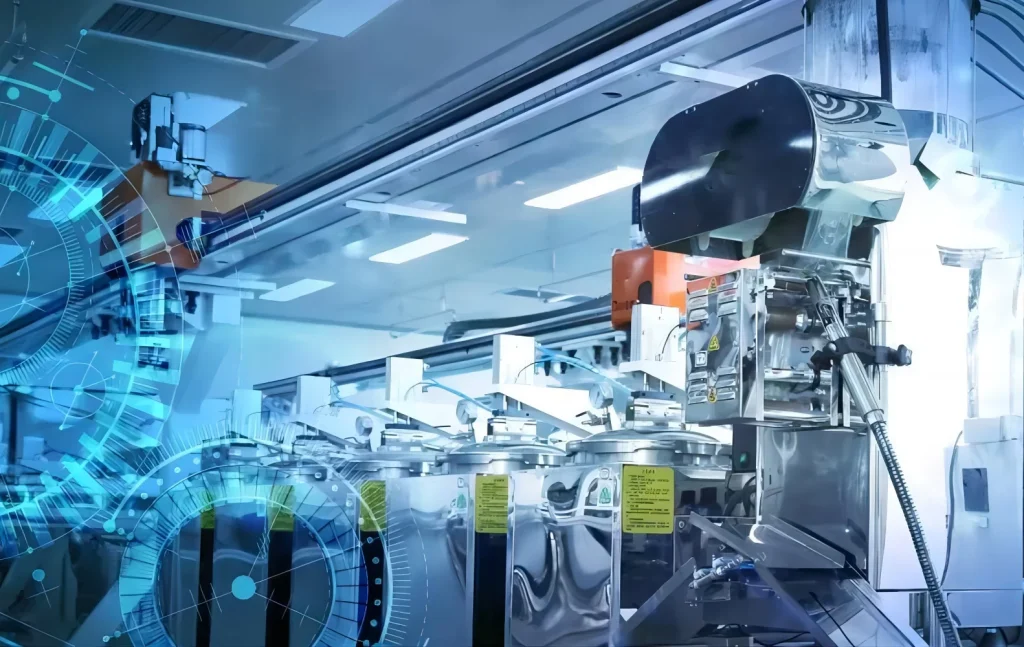

Laser welding is ideal for welding medical instruments due to its high precision and minimal thermal impact. In medical device manufacturing, the need for clean, non-contaminated welds is critical, especially in surgical tools and implants. Laser welding enables the creation of sterile, seamless joints without introducing foreign materials that might compromise hygiene or cause infections.

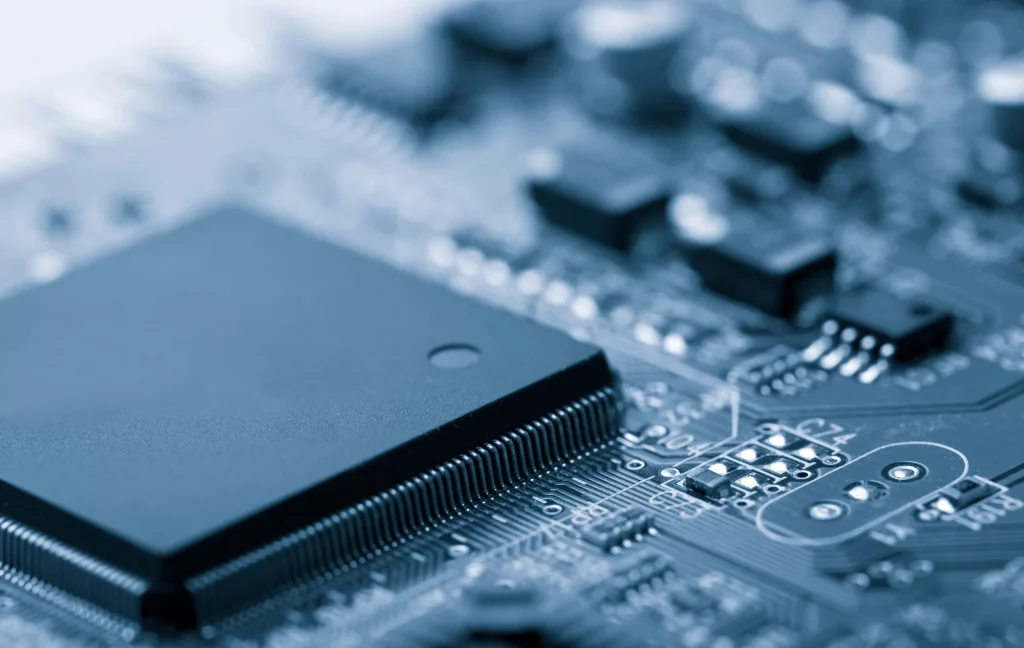

Electronic Communication:

In the electronics industry, laser welding is used for welding electronic components, including microelectronics, connectors, and heat-sensitive components. The precision and control offered by laser welding are essential for avoiding heat damage to delicate parts, such as semiconductors and printed circuit boards (PCBs), which are integral to electronic communication devices.

Hardware Products and Building Materials:

Laser welding is commonly used in the hardware industry to join metal parts used in construction and building materials. It offers high strength, durability, and precision, making it ideal for large-scale fabrication of structural components. Laser welding also helps minimize the amount of heat generated, reducing distortion and ensuring that materials retain their original properties.

Furniture and Electrical Appliances:

Handheld laser welding is used for welding stainless steel in furniture and electrical appliances, ensuring that the final products have a clean, high-quality finish. Stainless steel, being highly resistant to corrosion and durable, is often used in these industries, and laser welding ensures that the joints are not only strong but also aesthetically pleasing.

Automotive Technology:

In the automotive supply chain, handheld laser welding is used to efficiently weld components such as metal frames, exhaust systems, and body parts. Laser welding is highly beneficial in the automotive industry for its ability to weld lightweight materials like aluminum and advanced high-strength steels, which are increasingly used in modern vehicles to improve fuel efficiency and safety.

5. Welding Materials for Handheld Laser Welding Machines

Handheld laser welding machines can be used to weld a wide range of materials, including:

- Stainless Steel: Commonly used in industries requiring high corrosion resistance, such as medical devices and kitchen appliances.

- Carbon Steel: Ideal for welding in automotive and construction industries where strength is a key requirement.

- Aluminum: Lightweight and highly conductive, aluminum welding is particularly useful in the aerospace and automotive industries.

- Copper: Copper welding is used in electrical systems and other applications where high thermal and electrical conductivity is required.

- Galvanized Steel: Common in the construction industry for applications that require corrosion-resistant properties.

6. Limitations and Challenges

While handheld laser welding machines offer many benefits, there are also some limitations and challenges to consider:

- Material Limitations: Not all materials are suitable for handheld laser welding. Some materials, such as certain plastics, may not respond well to laser welding.

- Initial Investment: Handheld laser welding machines have a higher upfront cost compared to traditional welding equipment. However, this cost can be offset by the machine’s long-term benefits.

- Learning Curve: While the machines are generally user-friendly, operators still need training to fully utilize the technology’s capabilities and ensure high-quality results.

- Safety Considerations: Due to the intense laser beams, safety precautions must be followed, including protective eyewear and proper shielding to prevent injuries.

7. The Future of Handheld Laser Welding Machines

The future of handheld laser welding machines looks promising, with several key developments on the horizon:

- Advancements in Technology: Innovations in laser sources, automation, and AI are set to further enhance the capabilities of handheld laser welders. Expect greater control, faster processing speeds, and integration with Industry 4.0 technologies.

- Market Growth: As more industries recognize the advantages of laser welding, the market for handheld laser welders is expected to expand rapidly.

- Sustainability: Handheld laser welding is increasingly seen as an environmentally sustainable solution, with its low emissions and minimal waste contributing to more eco-friendly manufacturing processes.

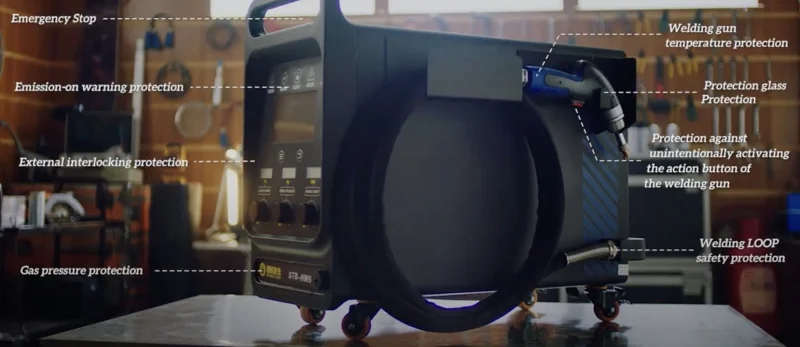

8. Handheld Laser Welding Machine Manufacturer

Strongest Laser is a leading manufacturer of handheld laser welding machines, offering a range of products with distinct advantages over competitors. Our machines are equipped with their own intellectual property laser source, ensuring superior performance and reliability. The integration design provides a one-stop service experience, simplifying the complexity of laser welding operations.

The dual-circuit refrigerant intelligent thermostat system ensures precise temperature control, while the small core diameter technology provides exceptional power and efficiency. This machine has undergone rigorous testing to ensure durability and long-lasting performance, making it a reliable tool for various industrial applications.

Moreover, Strongest Laser’s welding torch design is unique and easy to operate, reducing the likelihood of malfunctioning. Its operation is environmentally friendly and provides an ultimate energy-saving experience, making it a sustainable choice for businesses of different scales.

If you are considering laser welding, consult Strongest Laser handheld laser welding machine now to start your efficient welding journey!

Conclusion

Handheld laser welding machines are revolutionizing the welding industry by offering superior precision, speed, and flexibility. From automotive manufacturing to medical instrument production, these machines are opening new possibilities for industries requiring high-quality welds. While there are challenges to consider, such as initial cost and material limitations, the advantages and future potential of handheld laser welding make it a compelling choice for manufacturers. As technology continues to advance, handheld laser welding is poised to play an even larger role in the future of precision welding.