In the manufacturing industry, welding high-reflectivity thick plates such as aluminum has long been a formidable challenge that plagues many enterprises. The combination of the need for deep-penetration welding, the difficulty in laser absorption due to high reflectivity, and the proneness to porosity and cracks during aluminum welding has made this task a bottleneck for improving production efficiency and product quality. However, STRION LASER‘s MASTER X80 handheld laser welder has emerged as a game-changer, offering a powerful solution to overcome these obstacles. This case study will delve into how the MASTER X80 effortlessly tackles the challenges of welding high-reflectivity thick plates and why it stands out as the preferred choice for businesses in need.

Tackling High-Reflectivity Thick Plates – One-Pass Full Penetration with Double-Sided Formation

Challenges:

Deep-penetration welding demands extremely high energy density, which is hard to achieve with conventional welding equipment.

Aluminum’s high reflectivity makes laser absorption difficult, resulting in inefficient energy utilization and poor welding results.

Aluminum welding is prone to porosity and cracks, which severely affect the structural integrity and durability of the welded products.

STRION LASER Solution:

To address these challenges, STRION LASER has equipped the MASTER X80 with an industrial-grade high quality laser beam small-diameter laser source. This advanced laser source, combined with multiple anti-back-reflection technologies, ensures that the laser energy is effectively absorbed even by high-reflectivity materials like aluminum. Additionally, the integration of an intelligent process library allows the MASTER X80 to achieve deep penetration while maintaining the ideal weld width and excellent surface quality, eliminating the common issues of porosity and cracks.

Demonstration Setup:

Equipment: MASTER X80 high-power, water-cooled handheld laser welder – designed to provide stable and consistent performance even during long-hour operations.

Laser Power: 90% (one-pass full penetration, double-sided formation) – enabling efficient welding in a single pass, saving time and reducing production costs.

Wire: 5356 aluminum wire, Ø1.6mm – carefully selected to match the welding requirements of aluminum plates, ensuring strong weld joints.

Wire Feed Speed: 50 cm/min – optimized to coordinate with the laser power, ensuring uniform wire melting and proper fusion with the base material.

Welding Frequency: 30 Hz – contributing to a stable welding process with minimal spatter.

Wobble Width: 2.5 mm (stable, splash-free process) – enhancing the weld’s uniformity and aesthetics while preventing splashing that could damage the workpiece.

Welding Results:

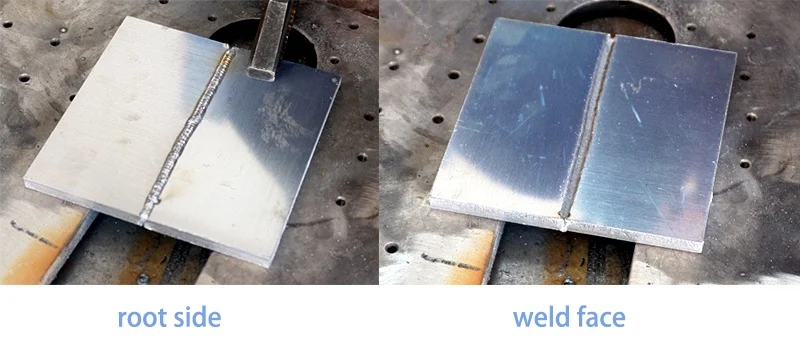

Complete penetration – ensuring the weld joint has sufficient strength to withstand various stresses.

Smooth and aesthetically pleasing front weld – meeting the high-quality standards of modern manufacturing, reducing the need for post-welding finishing.

Uniform and stable backside weld – guaranteeing the integrity of the entire weld, even on the reverse side of the thick plate.

Why Choose STRION for Thick High-Reflectivity Materials?

Deep-Penetration Welding Expert: The MASTER X80 boasts extreme beam quality that is specifically designed for deep and efficient welding. This superior beam quality allows it to conquer the challenges of thick-plate welding, ensuring that even the thickest high-reflectivity plates are welded with precision and strength.

High-Reflectivity Specialist: STRION LASER’s proprietary anti-back-reflection technology is a key differentiator. It safely and reliably handles a wide range of reflective metals, including aluminum, copper, and gold. This technology not only improves energy absorption but also protects the equipment from potential damage caused by back-reflected laser energy.

Stable & Efficient: Built with industrial-grade quality, the MASTER X80 is capable of 24/7 continuous operation. This reliability ensures that production lines run smoothly without frequent interruptions, maximizing productivity and minimizing downtime. Its efficient performance also helps reduce energy consumption and operational costs.

Expert Process Library Support: STRION LASER provides a comprehensive process database and a dedicated technical support team. The process library offers a wealth of pre-set parameters for different materials and welding scenarios, allowing users to quickly set up and start welding. The technical support team is always available to provide guidance and solutions, helping users unlock more application possibilities and overcome any technical difficulties they may encounter.

Continuous Improvement, Parameter Sharing, Supporting Smart Manufacturing

This practical demonstration not only validates the capabilities of the STRION LASER MASTER X80 handheld welding machine but also sets a new standard for welding high-reflectivity thick plates. With its “sword-like” beam that delivers precise and powerful energy, and “shield-grade” anti-reflection capability that ensures safe and efficient operation, the MASTER X80 provides a perfect solution for aluminum and other high-reflectivity thick plates.

If you are struggling with high-reflectivity materials or seeking to improve thick-plate welding efficiency and quality, STRION LASER is your ideal choice. The MASTER X80 handheld laser welder is not just a piece of equipment; it is a strategic investment that can help your business gain a competitive edge in the market.

Contact us today to access more practical parameters, request samples, and get a customized welding solution tailored to your specific needs. Let STRION LASER be your partner in overcoming welding challenges and driving your business towards greater success.