Proper torch inspection is essential for maintaining optimal performance and preventing overheating in laser welding systems. In this article,follow this procedure to ensure your torch operates efficiently and safely.

Protective Window and Focus Lens Checking

Contamination on the protective window and focus lens can lead to heat absorption, affecting the efficiency of the laser and causing overheating. Always inspect and clean the protective window and focus lens to prevent any debris or foreign particles that may compromise the torch’s performance.

Ensure Laser Alignment

The laser must be properly aligned. If the laser is not positioned in the middle or is on the wire, it can cause the laser to overheat the nozzle and tube. Regularly check the alignment to avoid unnecessary heat buildup, which can result in torch damage. Proper alignment ensures the longevity of your laser welding machine.

Monitor Duty Cycle and Work Time

Excessive work time in high-temperature environments can increase the temperature of the torch. Long work hours in these conditions will inevitably lead to a higher torch temperature. Monitor the duty cycle carefully to prevent overheating, and ensure the torch is not overused in such conditions.

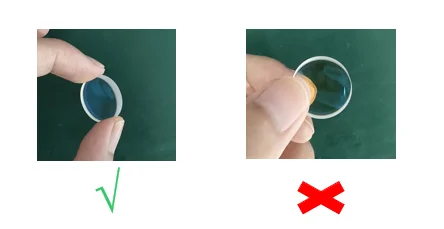

Handle with Care

Be cautious when handling the lens and window. Never touch the surface of the lens and window directly to avoid transferring oils and dirt, which can cause contamination. If welding quality is compromised, immediately check the lens and window for any dirt or damage. Additionally, sparks entering the tube can lead to overheating. Regular inspection of internal components is crucial to avoid this issue.