As titanium continues to dominate in aerospace, medical, and high-end manufacturing sectors, its welding challenges remain a critical concern for production engineers. STRION LASER has stepped up with advanced laser welding technologies and refined process strategies tailored to titanium’s unique metallurgy—delivering strength, precision, and purity where it matters most.

The Hidden Enemy: Contamination Embrittlement

Titanium is highly reactive at elevated temperatures. Even trace amounts of oxygen, nitrogen, or hydrogen can cause brittleness, delayed cracking, or complete weld failure.

Oxygen > 0.18% increases hardness by 50%, but reduces toughness by 80%.

Nitrogen > 0.03% elevates crack sensitivity by 5×.

Hydrogen > 150 ppm can result in delayed hydrogen-induced cracking.

STRION LASER’s recommendation: Ensure ultra-pure gas shielding and operate in fully decontaminated environments. Our systems support argon purity up to 99.999%, with dew point monitoring and trailing gas shields up to 25 L/min.

Oxide Scale Formation – A Silent Strength Killer

At temperatures above 400°C, titanium oxidizes at rates up to 1000× faster, forming brittle scales that hinder fusion and introduce defects. STRION advises:

Mechanical Cleaning: Use stainless steel brushes exclusively for titanium—never carbon steel.

Chemical Cleaning: Apply a 10% HNO₃ + 2% HF dip (≤10 min).

Environmental Control: Oil- and chlorine-free workspaces (Cl induces stress corrosion cracking).

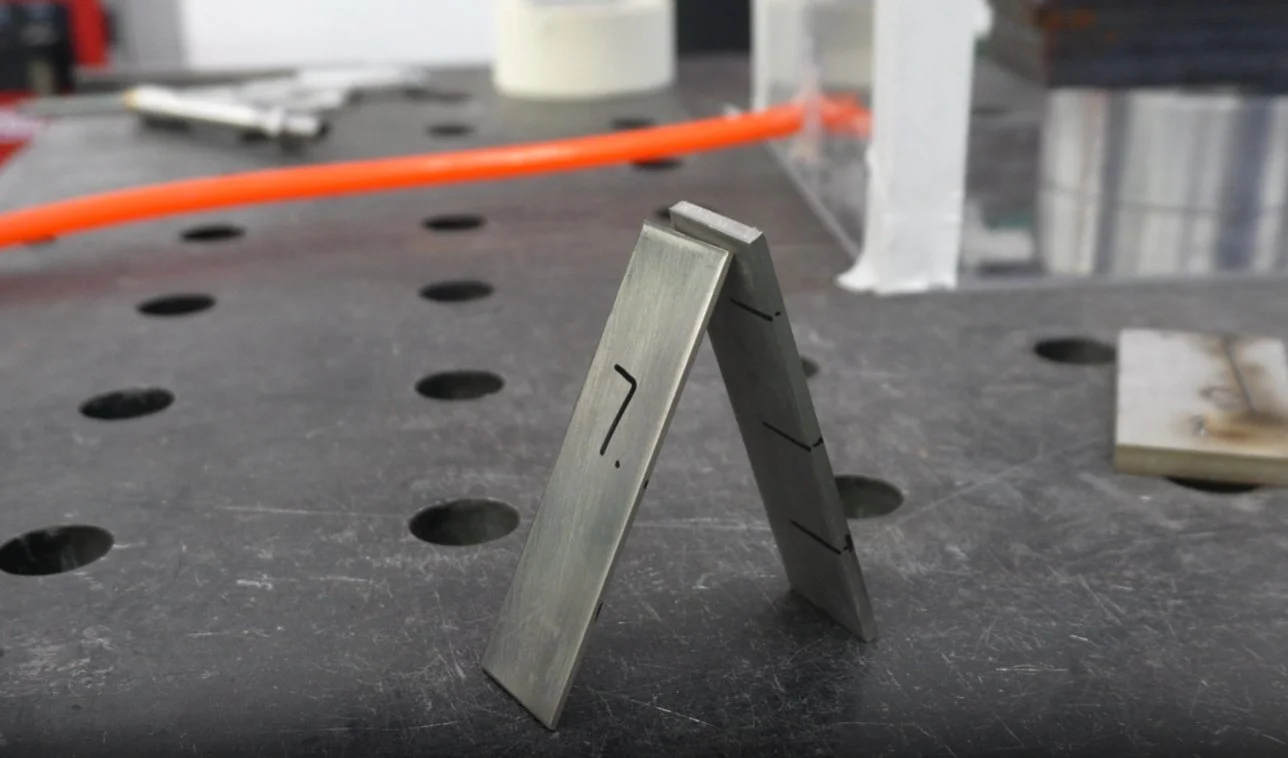

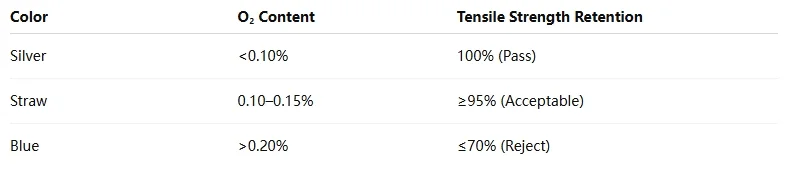

Weld Color Speaks Volumes

Weld bead color directly reflects oxygen contamination and mechanical performance:

Process Matters: Tailored Titanium Welding Approaches

GTAW (TIG) – Best for thin sheets and precision work; use 2% CeO₂ tungsten, DCEN polarity.

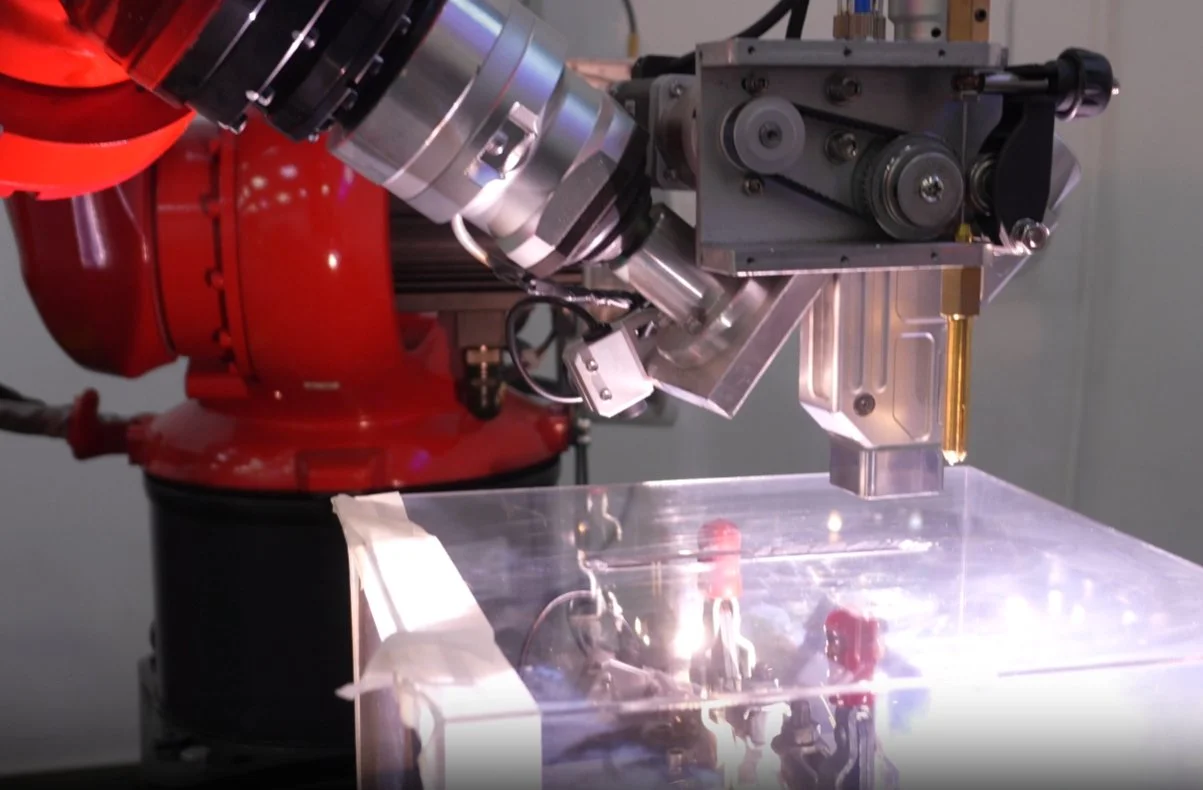

Laser Welding – Ideal for deep, narrow welds; wavelength 1070 nm, helium shielding preferred.

EBW (Electron Beam Welding) – For aerospace-grade thick parts; vacuum ≤ 5 × 10⁻⁴ mbar.

Non-Negotiables in Titanium Laser Welding

Gas Shielding

Primary gas: Ultra-high purity Ar (dew point ≤ -50°C)

Trailing: 20–25 L/min to protect welds during cooling

Backing gas: Oxygen < 50 ppm in purge chamber

Heat Input Control

Interpass temperature ≤ 150°C

Heat input limits: <3 mm: max 0.8 kJ/cm

3–6 mm: max 1.2 kJ/cm

6 mm: max 1.5 kJ/cm

Filler Metal Matching

Gr.1/2 → ERTi-2 (ELI grade recommended)

Gr.5 (Ti-6Al-4V) → ERTi-5, baked at 250°C × 2h

Gr.23 (Medical) → ERTi-23ELI with medical certification

Defect Diagnosis & Remedies

Porosity → Bake wire, double gas shielding

Cracking → Reduce restraint, hydrogen < 100 ppm

Lack of Fusion → HF acid cleaning, increase current by 10%

STRION LASER: Your Titanium Welding Partner

At STRION LASER, we don’t just provide machines—we engineer performance. Our titanium welding packages are fine-tuned for precision shielding, minimal heat distortion, and defect-free results, making us the preferred choice for manufacturers who demand nothing but excellence.

Ready to optimize your titanium welding process?

Visit www.strlaser-en.com or reach out to our expert support team for a tailored consultation.