In the world of precision manufacturing, selecting the right materials and welding process is critical to ensuring high-quality, durable products. Laser welding systems have emerged as a superior choice for a wide range of applications due to their ability to deliver exceptional precision and minimal thermal distortion. However, understanding the unique welding characteristics of different steel types is essential for optimizing performance and preventing defects. At STRION LASER, we specialize in providing advanced laser welder solutions that are tailored to meet the specific needs of various materials. In this comprehensive guide, we will explore the classifications of steel and their laser welding behavior, helping manufacturers achieve stable, high-efficiency, and high-quality results with our innovative technologies.

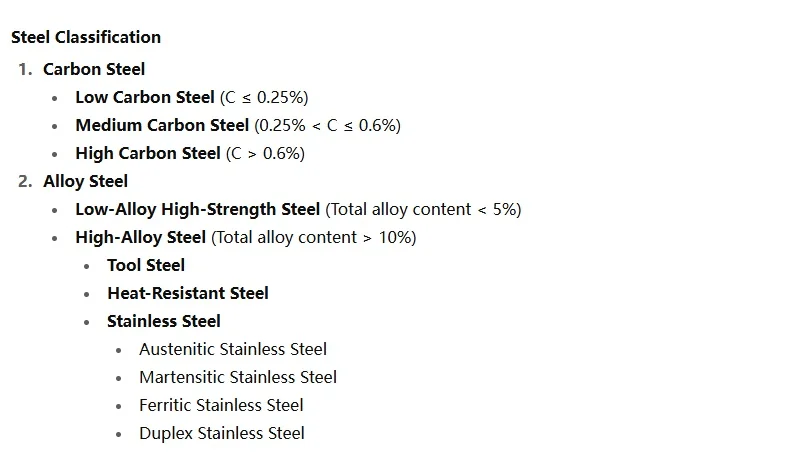

Steel Classification Overview

Steel is primarily classified based on its chemical composition and microstructure. Below are the major categories and subtypes:

Key Characteristics of Laser Welding

Carbon Steel

Low Carbon Steel

Low carbon steel exhibits excellent weldability. It allows the use of zero or positive defocus to increase the weld pool width and reduce spatter.High-purity argon or nitrogen is recommended as shielding gas, with a flow rate of 10–20 L/min.For thicker plates, backside gas shielding is required to ensure weld quality.

Medium Carbon Steel

Zero or positive defocus is recommended to enlarge the weld pool and stabilize the keyhole.

Preheating is necessary to prevent cracking due to increased hardness and brittleness.

Use high-purity argon as the shielding gas, with a flow rate of 15–25 L/min.

High Carbon Steel

Requires high heat input to slow the cooling rate and reduce martensite formation.

Due to low surface tension of the molten pool, keyhole collapse is likely — positive defocus is recommended to widen the weld pool and stabilize the keyhole.For thick plates, consider dual-beam or hybrid welding (laser + TIG) to improve fusion.Use high-purity argon as shielding gas, with a flow rate of 20–30 L/min.

Alloy Steel

Low-Alloy High-Strength Steel

Moderately increasing the heat input helps slow down the cooling rate and prevents overcooling in the heat-affected zone (HAZ). A positive defocus is recommended to widen the weld pool, reduce spatter, and extend the solidification time. High-purity argon should be used as shielding gas, with a recommended flow rate of 15–25 L/min.

Tool Steel

Tool steel has poor weldability. The heat-affected zone (HAZ) tends to form coarse martensite, resulting in extremely low ductility and toughness. Additionally, it is prone to oxidation and nitridation during welding, further reducing the weld’s mechanical properties. A shielding gas mixture of argon with 10–20% helium is recommended to improve arc stability and reduce contamination.

Heat-Resistant Steel

Due to its high melting point, low thermal conductivity, strong hardenability, and tendency toward oxidation and nitridation, heat-resistant steel poses significant welding challenges. These characteristics often lead to issues such as cracking, porosity, and poor fusion during the welding process, resulting in generally poor weldability.

Stainless Steel

Austenitic Stainless Steel

Weldability: Excellent, well-suited for laser welding.

Characteristics: High thermal expansion coefficient; prone to hot cracking during welding.

Recommendations: Use low power with short focal length;

Control line energy; preheating may be necessary;

Shielding gas: High-purity argon at 15–25 L/min to prevent oxidation.

Martensitic Stainless Steel

Weldability: Poor.

Characteristics: Strong hardening tendency; high risk of cracking.

Recommendations: Preheat to 200–300°C; post-weld tempering is essential;

Use positive defocus to widen the molten pool;

Shielding gas: Argon or Ar+He mixture at 20–30 L/min.

Ferritic Stainless Steel

Weldability: Moderate.

Characteristics: High thermal conductivity; coarse-grained heat-affected zone (HAZ); prone to embrittlement.

Recommendations: Use higher energy density and fast welding speed;

Post-weld heat treatment improves ductility;

Shielding gas: Argon at 15–25 L/min.

Duplex Stainless Steel

Weldability: Good, but phase balance must be controlled.

Characteristics: Reduced austenite content after welding may affect corrosion resistance.

Recommendations: Control heat input to maintain appropriate phase ratio

Consider hybrid welding methods (e.g., laser + TIG)

Shielding gas: Argon or Ar+N₂ mixture at 20–30 L/min

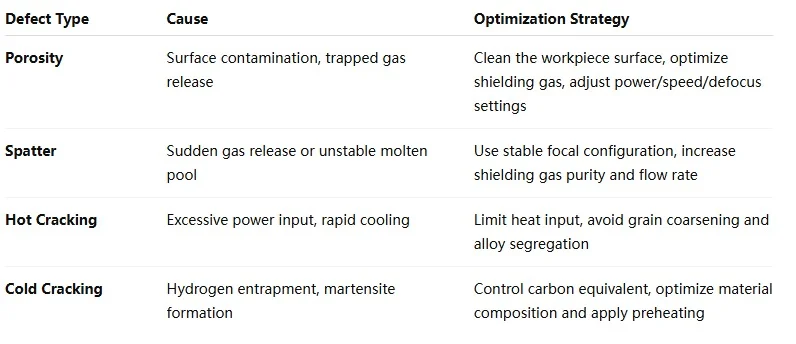

Common Laser Welding Defects and Optimization Measures

Note: For galvanized steel, it is recommended to preheat the material to the boiling point of zinc (908°C) or grind off the zinc coating prior to welding to prevent porosity and cracking caused by zinc vapor.

Laser welding, with its advantages of high precision, low heat input, and minimal deformation, is increasingly replacing traditional welding methods and becoming the preferred process for various types of steel. STRION LASER is committed to in-depth research on the welding behavior of different metal materials, offering customized, professional solutions to help clients achieve high-efficiency and high-quality laser welding production.

For tailored welding parameter recommendations based on your material, please visit the STRION LASER official website or contact our technical support team.