In today’s increasingly competitive metal furniture industry, manufacturers face persistent challenges such as high production costs, low efficiency, and heavy reliance on manual labor. Against this backdrop, achieving cost reduction and efficiency improvement through technological innovation has become a key driver of competitiveness. STRION LASER welding solutions are designed to directly address these pain points, offering targeted solutions that help furniture manufacturers accelerate their shift toward intelligent, efficient, and high-quality production.

STRION LASER Welding Solutions for the Furniture Manufacturing Industry

To meet the diverse, small-batch, and flexible production demands of the furniture manufacturing sector, STRION LASER offers a comprehensive range of welding solutions:

- Handheld Laser Welding Machines – Ideal for accessories and small parts, providing high flexibility and adaptability.

- Platform Laser Welding Systems – Suited for small-batch finished products, balancing precision and stability.

- Robotic Laser Welding Solutions – Designed for standardized mass production, easily integrated into automated production lines to significantly boost consistency and efficiency.

Typical Application Cases of Laser Welding Machine for Furniture

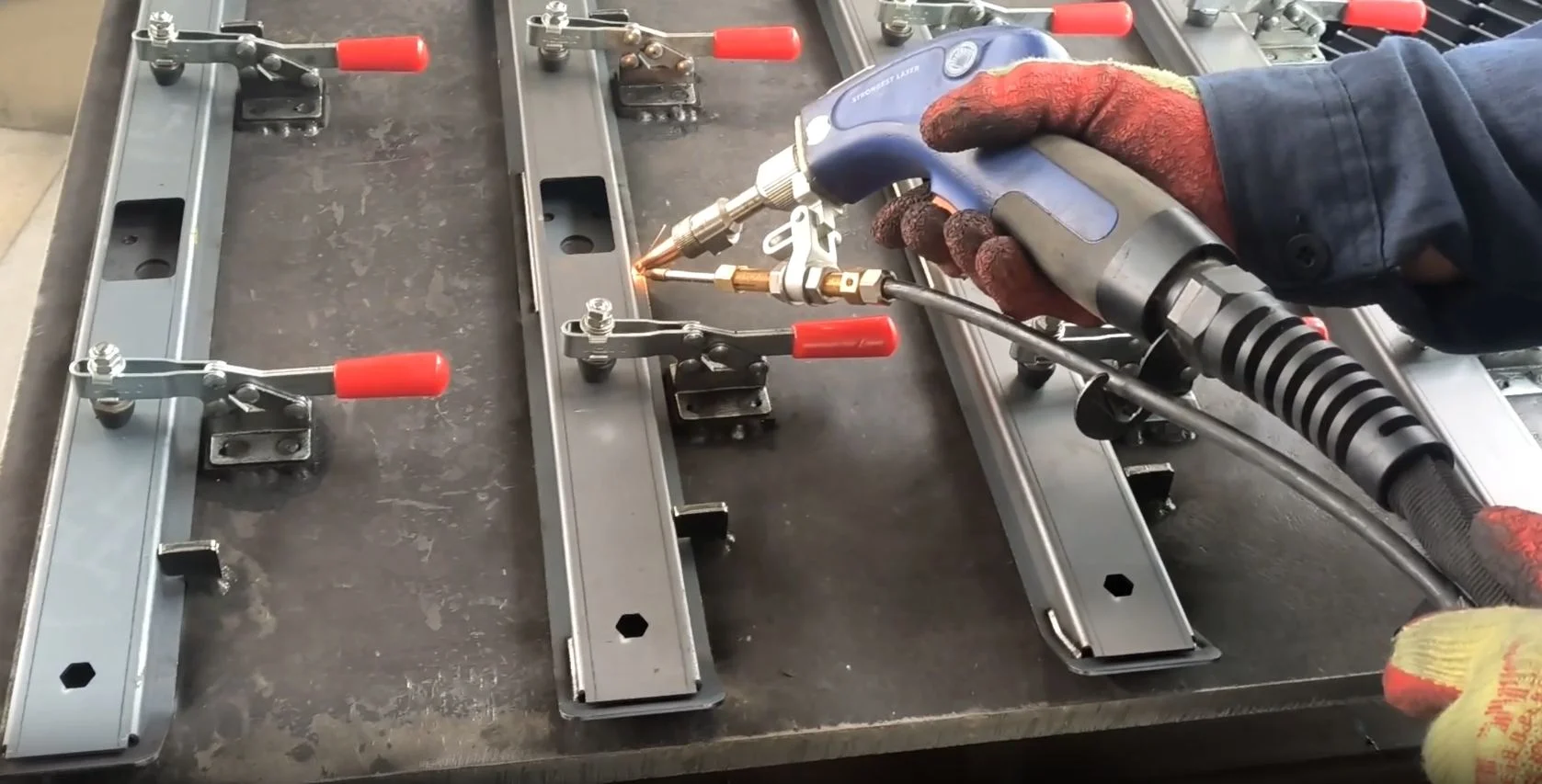

Furniture Accessories & Parts – Handheld Laser Welding Solution

Industry: Metal bed components

Equipment: STR-HW350 Handheld Laser Welding Machine

Advantages: Annual savings of over ¥120,000 in polishing costs and ¥60,000 in labor costs, totaling more than ¥180,000 per year.

Industry: Chair connector welding

Equipment: STR-HW450 Handheld Laser Welding Machine

Advantages: Small heat-affected zone reduces polishing time from 3 minutes per piece to just 1 minute—cutting polishing time by threefold. Average productivity increases by 150 chairs per operator per day.

Industry: Chair leg accessories

Equipment: STR-HW550 Handheld Laser Welding Machine

Advantages: Tackling the challenge of wide weld seams, STRION LASER’s dual-wire welding technology enabled reliable joining of 5mm plates and 1.5mm tubes. In bending strength tests, the welded joints showed no cracking, earning high customer recognition for quality and reliability.

Case Study: Finished Furniture Welding – Automated Laser Welding Solution

Industry: Dining chair leg manufacturing

Equipment: Laser welding platform retrofitted onto existing OTC robot

Advantages: Successfully eliminated post-weld grinding processes, achieving smoother surface quality. The solution reduces manual finishing requirements and saves over ¥80,000 annually in grinding costs.

Core Value of STRION Laser Welding Equipment

STRION Laser welding solutions deliver clear advantages for the metal fabrication and furniture manufacturing industries, making them an excellent choice for any laser welding machine manufacturer looking to enhance their offerings:

- Significantly Reduce Welding Costs: Compared with conventional MIG/MAG welding, laser welding lowers unit welding costs by up to 50%.

- Optimize Workforce Structure: Minimize reliance on highly skilled welders. With intuitive interfaces and smart process packages, general operators can master welding tasks after short training.

- Simplify Post-Processing: Laser weld seams are smooth and precise, eliminating most grinding and polishing. This saves both production time and labor expenses.

By integrating these benefits, STRION Laser helps manufacturers improve efficiency, cut operational costs, and achieve higher product quality.

Partner With STRION Laser – Global Distributor Program

As laser welding reshapes modern manufacturing, STRION Laser is actively seeking global distributors and agents to expand our international market presence. We provide competitive products, full technical support, and marketing resources to help partners achieve long-term growth.

Email: str@strlaser.com

Website: www.strlaser-en.com

Join us and become part of the next wave of laser welding innovation worldwide.