Titanium alloy has earned its reputation as a standout among advanced lightweight structural materials, prized for an impressive blend of high strength-to-weight ratio, outstanding corrosion resistance, and reliable thermal stability. Recently, STRION LASER demonstrated its mastery in precision laser welding through a remarkable project: joining 0.5mm titanium alloy components to craft a teapot. The result? Welds that meet the strictest standards for strength, hermetic sealing, and radiographic inspection.

Why Titanium Alloy?

Titanium alloys strike a rare balance: they match the strength of steel while weighing in at just 60% of its density, making them a go-to material in aerospace engineering, medical device manufacturing, and high-end consumer goods. A naturally forming dense oxide film shields them from corrosion in acidic, alkaline, and marine environments, and they hold steady even under temperatures ranging from 300–500°C—qualities that make them indispensable for high-performance applications.

However, titanium’s reactivity presents unique welding hurdles. When heated above 500°C, it readily reacts with oxygen, nitrogen, and hydrogen in the air, forming brittle compounds that weaken weld toughness. Taming this reactivity demands meticulous control and sophisticated laser welding systems—exactly where STRION LASER’s expertise shines.

Welding Requirements for the Titanium Teapot

For this project, the welds needed to excel on three fronts:

A smooth, uniform finish with zero signs of oxidation

Complete penetration to ensure airtight sealing (critical for a teapot’s functionality)

Compliance with rigorous radiographic and tensile testing standards

STRION LASER’s Optimized Welding Parameters

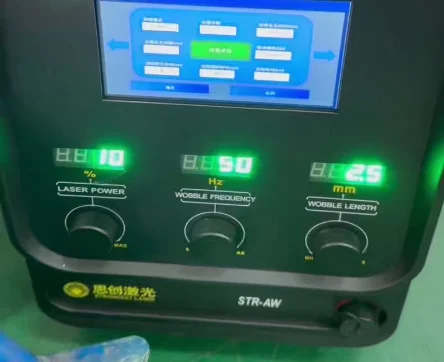

To achieve these results, the team fine-tuned key parameters:

Laser Power: 10%

Pulse Frequency: 2000Hz

Scanning Speed: 5mm/s

Wobble Width: 0.2mm

Duty Cycle: 100%

Travel Speed: 80mm/s

This precise setup enabled deep, consistent penetration, evenly distributed energy, and reliable weld formation—even across the delicate 0.5mm titanium walls.

Key Considerations for Titanium Alloy Welding

Shielding Gas Control: Protecting the weld zone is critical. By directing side-blowing shielding gas from already welded areas toward unwelded sections, we prevent welding fumes from contaminating the molten pool—keeping oxidation at bay.

Porosity Prevention: Gas bubbles (porosity) can form if hydrogen is released during solidification or if shielding is inadequate. STRION addresses this with high-purity argon, thorough pre-weld cleaning (removing oils and oxides), and tight parameter control.

Mechanical Performance: The final welds delivered on strength, sealing, and durability—ensuring the teapot can withstand daily use for years to come.

Conclusion

The success of this titanium alloy teapot project is more than a single feat; it’s proof of STRION LASER’s ability to tackle titanium’s trickiest welding challenges. Whether for high-end consumer products, aerospace components, or life-saving medical devices, our laser welding systems bring the precision, reliability, and consistency needed to fully leverage titanium’s potential.

By pairing cutting-edge technology with a deep understanding of material behavior, STRION LASER continues to push the boundaries of what’s possible in laser welding. For your next titanium alloy project—no matter how intricate—trust us to turn complex challenges into seamless, high-quality results.