STRION LASER 100% Self-Developed Welding System|Engineered for Zero Downtime

Every minute a laser welder stops on the production line results in lost output, delayed orders, and shrinking profit. Few manufacturers fully realize how much hidden cost lies behind these “unexpected shutdowns.”

The real cause of this production headache often comes from mismatched system architectures, reliance on external suppliers, and slow service response when issues occur.

At STRION LASER, we understand the importance of long-term stability. That’s why we commit to a fully self-developed and self-manufactured approach—embedding reliability into every component, every process, and every service step. Our goal is simple: eliminate your downtime concerns at the source and ensure worry-free operation.

Concern 1: Incomplete Service System Leading to Unresolved Issues

Issue Description:

When problems occur, many manufacturers struggle with limited communication channels, insufficient technical support, and incomplete solutions. Minor faults often escalate into major disruptions and repeatedly resurface, severely affecting production efficiency.

Root Cause Analysis:

Traditional service models involve long communication chains, unclear responsibilities, and a lack of structured remote diagnostic tools. As a result, response times are slow, problem identification is inaccurate, and troubleshooting remains incomplete—making it difficult to resolve issues at their source.

STRION LASER’s Solution:

STRION LASER has built a direct, efficient service structure designed to provide clear, timely, and effective support. Our goal is to be the most dependable partner in your production process.

- Fast Response

Our dedicated service team offers precise remote diagnostics and can respond immediately to customer requests, significantly reducing downtime. - Professional Support

We provide comprehensive technical assistance—from routine equipment maintenance to process optimization—to help improve overall production performance. - Remote Troubleshooting

Both the main unit and welding gun support remote firmware upgrades via the STRION mobile app, enabling quick resolution of common issues and greatly improving maintenance efficiency.

Concern 2: Frequent Equipment Shutdowns Disrupting Production

Issue Description:

Many users experience unexpected shutdowns when operating handheld laser welders, causing production lines to halt and creating serious delays.

Root Cause Analysis:

When a machine is built from components sourced from multiple brands, compatibility issues are common. Failures occur more frequently, troubleshooting becomes complicated, and repairs rely on multiple parties. This not only increases maintenance costs but also slows production and jeopardizes project schedules.

STRION LASER’s Solution:

STRION LASER avoids mixed-component assembly entirely. By developing and manufacturing every core system in-house, we ensure seamless coordination across all modules and deliver stable, reliable performance from the source.

Laser Source System

Our self-developed laser source and core optical components offer longer optical path lifespan and more consistent energy output, reducing the chance of failure at its origin.Control System

A fully customized control program enables millisecond-level response and precise synchronization between all modules—eliminating command delays or miscommunication and ensuring smooth welding operations.

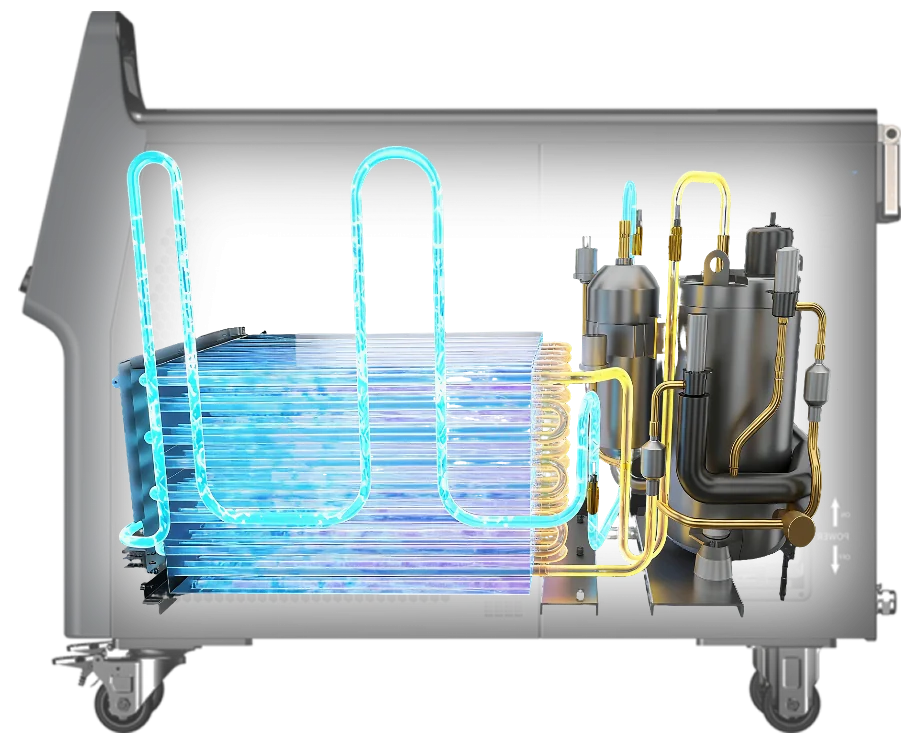

Cooling System

STRION LASER’s aerospace-grade dual-loop direct refrigerant cooling system delivers significantly higher heat dissipation efficiency than conventional technologies. It supports stable, round-the-clock operation even under extreme environments and long working hours.

Welding Gun System

The integrated welding gun is independently designed for lightweight handling, flexible operation, and reduced operator fatigue, while preventing common issues such as irregular beam swing or motion instability.

Concern 3: High Supply Risks When Core Components Depend on External Vendors

Issue Description:

When key components rely on external procurement, quality often varies and unified quality control becomes difficult. Any disruption in supply can directly affect production continuity and project delivery, leading to significant losses for customers.

Root Cause Analysis:

External suppliers operate under different quality systems, and key components often lack consistent standards, making full-process quality traceability nearly impossible. In addition, outside supply chains are sensitive to market fluctuations, logistics issues, and other uncertainties, resulting in unstable delivery and a higher risk of production interruptions.

STRION LASER’s Solution:

STRION LASER keeps all critical components under its own control. Through fully localized, in-house production, we ensure consistent quality and reliable supply for every machine we deliver.

Reliable Quality Control

A complete quality assurance system—from component selection to final machine testing—ensures every unit meets strict standards and delivers consistent, dependable performance.Stable Delivery

Full in-house production minimizes dependence on external supply chains, reducing the risk of delays and ensuring clear, predictable delivery schedules that keep customer production plans on track.

Contact STRION LASER

📞 +028-85812068

🌐 www.strlaser-en.com

📧 str@strlaser.com