Copper welding has long been recognized as one of the most technically demanding tasks in the field of precision manufacturing. As a leading innovator in laser welding solutions, STRION LASER is proud to share advanced strategies and best practices for high-quality copper (Cu) welding—particularly purple copper—drawing on extensive field experience and our latest equipment capabilities.

Understanding the Unique Challenges of Copper Welding

Copper’s distinct material properties pose several challenges:

High Reflectivity: Copper reflects over 90% of near-infrared laser light (1064nm), making energy absorption difficult. To overcome this, STRION LASER recommends using shorter wavelength lasers such as green (515nm) or blue (450nm) to significantly enhance absorption.

High Thermal Conductivity: With a thermal conductivity of around 400 W/m·K, copper rapidly dissipates heat. This requires high energy density and rapid heating to achieve full penetration.

Pre-Welding Preparations for Superior Results

To ensure welding consistency and structural integrity, STRION LASER recommends the following preparations:

Shielding Gas: Use high-purity (≥99.99%) argon or helium with dual-layer nozzles or backside shielding to isolate the weld pool from air.

Gas Flow Control: Maintain a stable flow rate (15–25 L/min) to prevent turbulence from disrupting the molten pool.

Surface Cleaning: Degrease using acetone or alcohol, and mechanically polish the surface using a stainless steel brush to remove oxide layers.

Defocusing Adjustment: Use negative defocus (focus point beneath the surface) to enhance penetration.

Preheating and Slow Cooling: Preheat to 100–300°C to reduce thermal stress and cracking risk.

Post-Weld Annealing: Apply heat treatment to relieve residual stress and enhance durability.

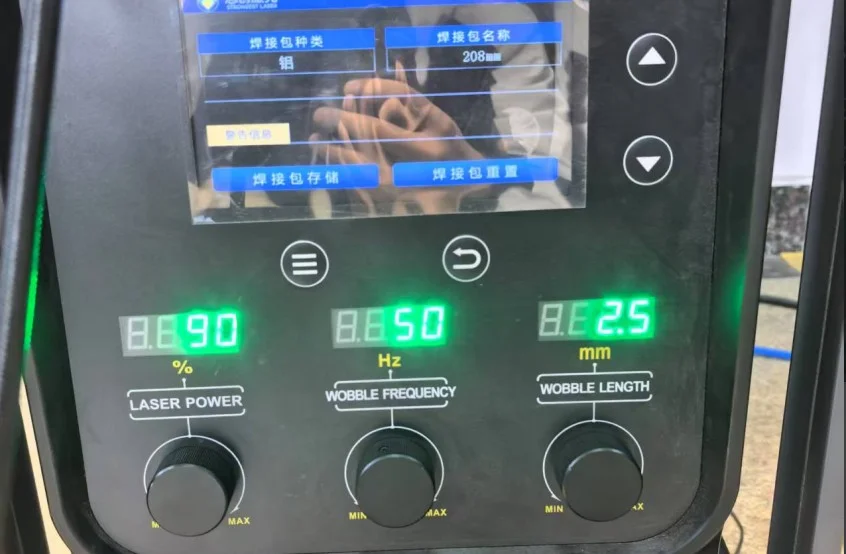

STR-HW550: Precision-Engineered for Copper Welding

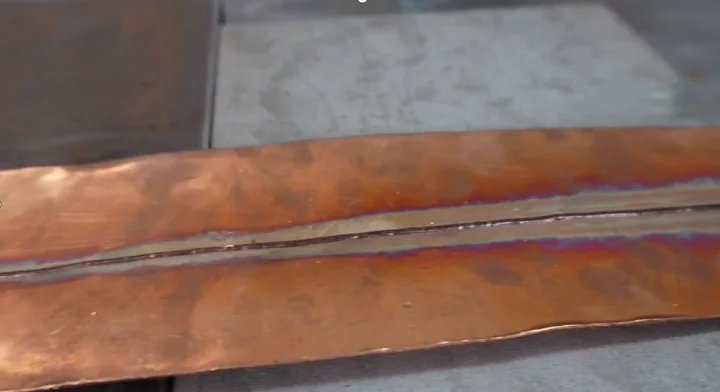

The STR-HW550, a flagship handheld laser welding model by STRION LASER, is engineered to meet the precision demands of copper welding. For instance, when welding 1.5mm-thick purple copper, recommended parameter settings include:

- Laser Power: 90%

- Wobble Frequency: 50Hz

- Wobble Length: 2.5mm

These optimized settings ensure a stable, uniform weld while minimizing heat-affected zones.

Key Operational Guidelines

- Filler Material: Choose compatible copper alloys or low-melting-point filler wire such as silicon bronze.

- Welding Angle: Maintain a torch angle below 70° to ensure proper beam coupling and control.

- Protective Gear: Always wear gloves and laser safety goggles, especially due to copper’s high reflectivity.

- Feeding Accessories: Use U-shaped wire feed rollers and graphite liners to ensure smooth wire delivery.

- Start Technique: Enable preheating or apply wire feeding delay to guarantee complete fusion at the weld start point.

STRION LASER remains committed to pushing the boundaries of laser welding technology, offering robust solutions for even the most challenging materials like copper. With our deep technical know-how and precision-engineered equipment, we help industries achieve faster, smarter, and more reliable welding outcomes.

For more insights or technical consultation, please contact us or visit www.strlaser-en.com.