What is a Membrane Wall?

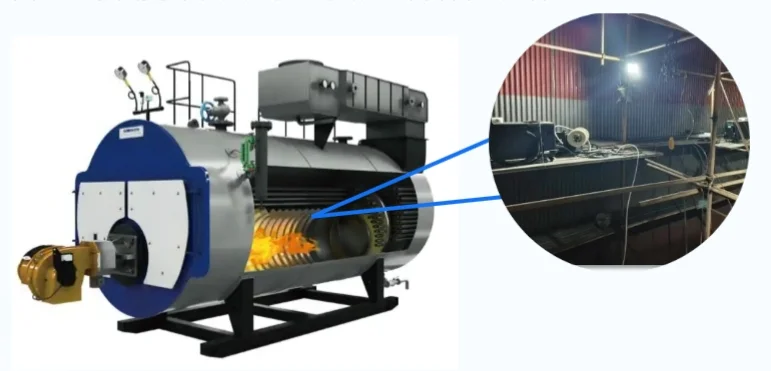

Membrane Wall (also known as Membrane Water-Cooled Wall) A membrane wall is a sealed tube panel structure in boilers, composed of multiple steel tubes welded together with flat bars or fins. These tube panels are then assembled to form an integrated wall surface. Membrane walls are primarily designed to efficiently absorb radiant heat from the furnace and protect the boiler’s refractory walls.

Main Material: Grade 20 carbon steel (a high-quality low-carbon structural steel with approximately 0.2% carbon content), thickness around 6 mm.

Is laser welding a suitable method for repairing membrane walls?

Membrane wall repair is a type of laser cladding, which falls under the category of laser additive manufacturing.Laser cladding is an advanced surface modification technology that uses a high-energy laser beam to melt and deposit a layer of material with special properties onto the surface of the base metal. This process significantly enhances the component’s resistance to high temperatures, corrosion, and wear.

By fine-tuning laser parameters—including power output, welding speed, and spot size—laser welding enables precise control over penetration depth and weld bead width. Practical trials have confirmed that the process delivers comparable results in membrane wall repair applications.

(STRION LASER handheld welder is working on membrane wall repair)

Limitations of Traditional Repair Methods:

Conventional repair requires a minimum thickness of over 1 mm

Thermal spray welding applies only 0.2–0.3 mm per pass

Thermal spraying is complex, low in efficiency, and prone to peeling

Arc cladding uses flux-cored wire and causes significant deformation

Arc welding cladding demands highly skilled welders

Not suitable for beginners, resulting in high labor costs

STRION LASER Targeted Solutions

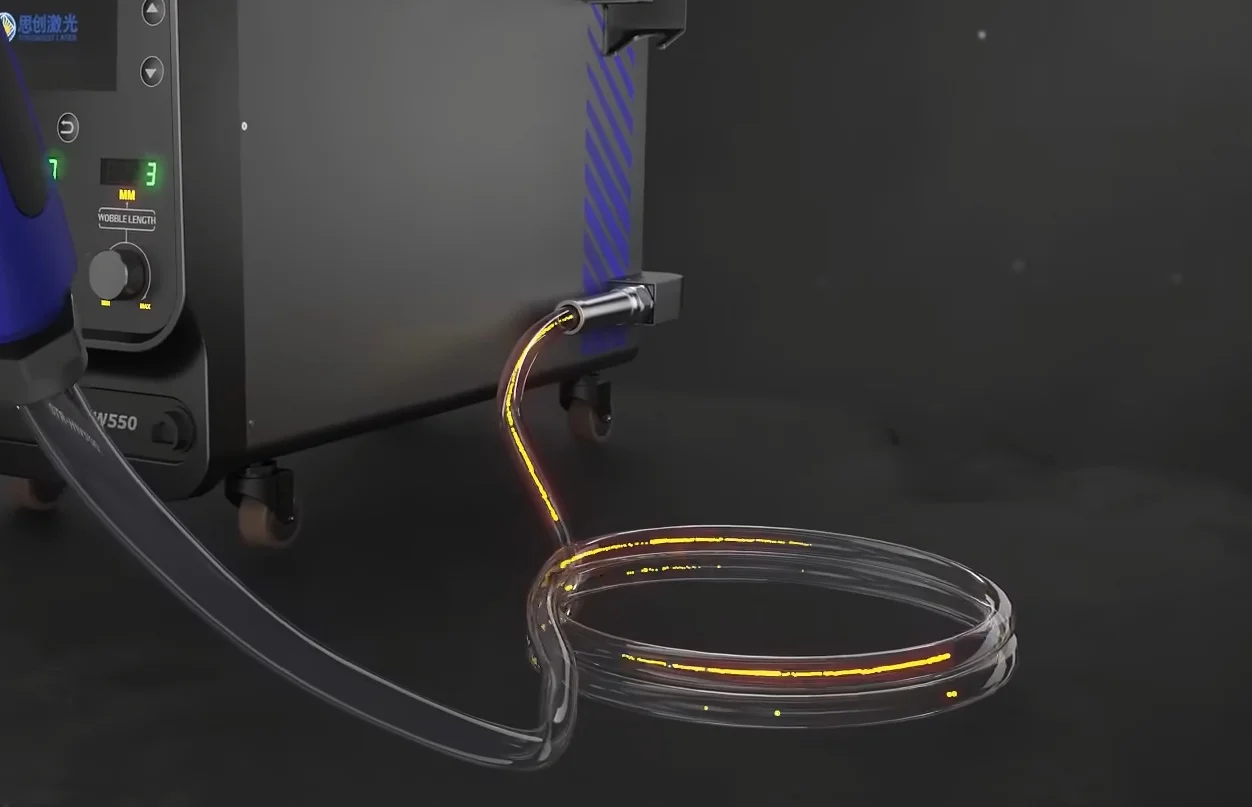

Revolutionary Light Source

This membrane wall laser repair uses special 625 welding wire, suitable for corrosion resistance and extreme temperature environments (high or low).

Combined with STRION LASER’s industrial-grade single-mode small-core fiber laser source, the high energy density paired with nickel alloy welding wire enables precise melting.

This results in fast cladding speed, stable penetration depth, uniform overlay area, and high controllability.

Traditional repair speed is 1.5 ㎡/day, while STRION LASER handheld welding repair reaches up to 2 ㎡/day, far exceeding customer expectations.

STRION LASER Handheld Welder with Superior Environmental Adaptability

The membrane wall repair site is a near-enclosed space with on-site temperatures reaching 40–50°C. Thanks to STRION LASER’s proprietary dual-loop refrigerant direct cooling technology, the handheld laser welder operates stably for extended periods.It has been used continuously on-site for 15 days straight (three shifts), running 24 hours non-stop, truly withstanding the demands of 7×24-hour operation.

With IP53 protection against metal dust, STRION LASER handheld welders confidently withstand harsh industrial environments, ensuring reliable production support for customers.

Precise control of laser output

In extreme and continuous nonstop working environments, maintaining stable penetration depth and consistent cladding height requires very tight control of laser source energy fluctuations. STRION LASER handheld welders achieve a power dynamic instability of less than ±0.5% and an annual power degradation of ≤1%.

(Long-term welding power fluctuation less than 1%)

(Cladding Application Results)

Proven in the critical field of boiler membrane wall repair, STRION LASER handheld welding has demonstrated undeniable advantages: faster construction speed, minimal deformation, superior quality, and cost savings.This breakthrough technology is setting a new industry standard and exceeding customer expectations.