In today’s fast-paced industrial landscape, precision welding of aluminum has become a critical requirement for sectors ranging from automotive and aerospace to electronics and medical device manufacturing. Aluminum’s unique properties—such as low density, high corrosion resistance, and excellent thermal conductivity—make it an ideal material for lightweight, high-performance components. However, its high reflectivity, softness, and susceptibility to warping pose significant challenges for achieving consistent, high-precision welds, especially in large-scale or complex production scenarios. Conventional welding methods often struggle to meet the strict quality standards demanded by modern industries, leading to inefficiencies, rework, and increased costs. Against this backdrop, STRION LASER has emerged as a pioneer, leveraging cutting-edge robotic technology to redefine precision aluminum welding.

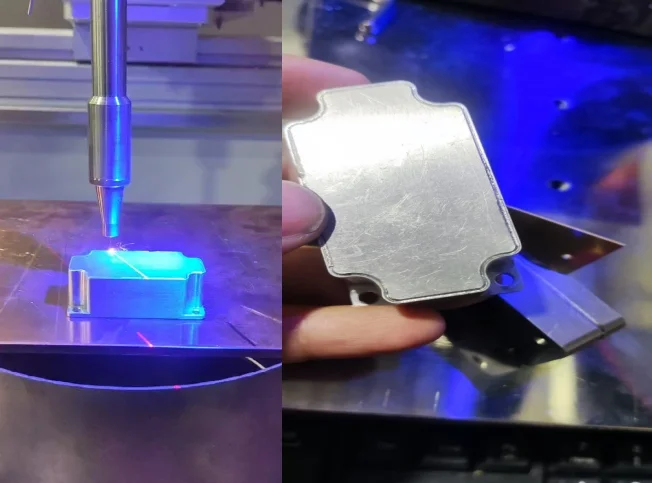

STRION LASER recently demonstrated the advanced capabilities of its AW550pro robotic welding system on aluminum boxes, showcasing high-precision and consistent welds for demanding industrial applications—addressing the long-standing pain points of aluminum welding and proving its value in mission-critical production environments.

Materials and Welding Process

The AW550pro robotic system stands out for its exceptional versatility, efficiently welding a diverse range of materials beyond aluminum, including copper, nickel, titanium, and stainless steel. This broad material compatibility is a game-changer for manufacturers handling multi-material projects, eliminating the need for multiple specialized welding systems and streamlining production workflows. Operating in a continuous welding mode, the system ensures seamless, uninterrupted welds—critical for maintaining uniformity in large or complex components like aluminum boxes. Whether used for intricate electronic enclosures or heavy-duty industrial containers, the AW550pro’s adaptability makes it a go-to solution for complex aluminum laser welding and other precision welding projects, catering to the varied needs of modern industries.

Key Welding Parameters

The success of the AW550pro’s precision welding is rooted in its optimized, industry-proven parameters, tailored to balance speed, accuracy, and quality:

Welding speed: 800 mm/min – This high-speed operation significantly reduces cycle times, boosting production efficiency without compromising weld integrity—ideal for high-volume manufacturing lines.

Wobble amplitude: 0.3 mm – The minimal wobble amplitude ensures tight control over the weld pool, preventing excessive heat input and minimizing material distortion, a common issue with aluminum welding.

Laser power: 28% – The precisely calibrated laser power delivers just the right energy for aluminum’s unique properties, avoiding over-welding (which can cause porosity or cracks) and under-welding (which leads to weak joints).

Welding Performance

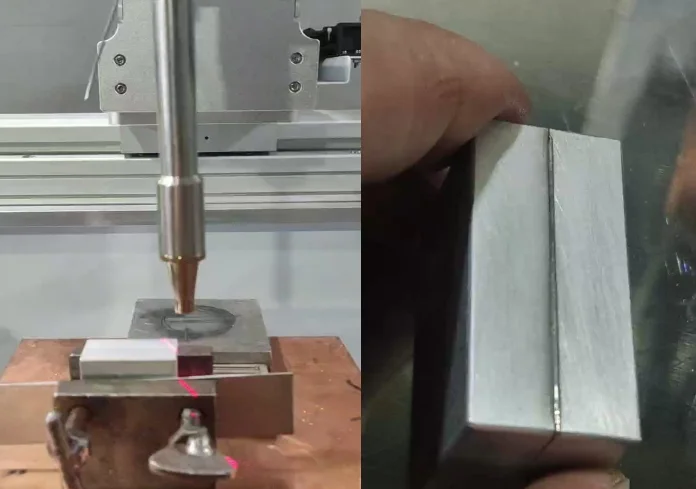

The results of the AW550pro’s demonstration speak volumes about its precision and reliability. The system produced weld seams narrower than 0.3 mm—far thinner than the industry average for aluminum welding—ensuring a clean, unobtrusive finish that meets the aesthetic and functional requirements of high-end components. Equally impressive was the minimal spatter generated during the process; this not only reduces post-welding cleanup time but also prevents contamination of sensitive parts (such as electronic components inside aluminum boxes). The excellent surface finish of the welds further eliminates the need for time-consuming grinding or polishing, cutting down on post-processing costs and accelerating time-to-market for finished products. This level of performance underscores the AW550pro’s ability to deliver consistent, high-quality results in even the most demanding robotic laser welding applications.

Challenges and Solutions

No welding project is without obstacles, and the AW550pro demonstration was no exception. Two primary challenges emerged during the process: fixturing (securing the aluminum boxes to prevent movement during welding) and material flatness (aluminum’s tendency to warp, which can disrupt weld alignment). The AW550pro robotic system addressed these challenges head-on with its inherent flexibility and precise control. Its advanced robotic arm features multi-axis movement, allowing it to adapt to slight variations in fixturing or material flatness in real time—ensuring the laser stays aligned with the weld joint throughout the process. Additionally, the system’s integrated sensors continuously monitor the welding area, making micro-adjustments to parameters like speed and power to compensate for any deviations. This proactive problem-solving capability guarantees stable and reliable aluminum laser welding, even in less-than-perfect production conditions, and minimizes the risk of costly errors.

This successful demonstration is more than just a proof of concept—it confirms STRION LASER’s leadership in providing automated robotic welding solutions that meet the highest standards of precision welding across multiple materials and industries. By combining versatility, speed, and pinpoint accuracy, the AW550pro robotic system empowers manufacturers to overcome the unique challenges of aluminum welding and elevate their production capabilities.

Conclusion

As industries continue to push the boundaries of precision and efficiency, the demand for reliable, automated welding solutions will only grow. STRION LASER’s AW550pro robotic system is not just a tool—it’s a strategic investment that helps businesses stay ahead of the curve, reduce costs, and deliver products of unmatched quality. Whether you’re manufacturing aluminum enclosures for electronics, lightweight components for aerospace, or corrosion-resistant parts for marine applications, the AW550pro is designed to meet your specific needs.

If you’re looking to enhance your aluminum welding processes, streamline multi-material production, or achieve consistent precision in automated welding, STRION LASER is your trusted partner. Our team of experts is ready to provide personalized consultations, share detailed technical specifications, and even arrange custom demonstrations of the AW550pro robotic system tailored to your operations. Contact STRION LASER today to discover how the AW550pro can transform your welding workflows and help you achieve new heights of industrial excellence.