One of the most common misconceptions in the handheld laser welding market today is the belief that laser power is everything. Consumers are led to assume that higher power automatically means better welding performance. But is that really the case?

In reality, with the rapid evolution of laser technology, the era of choosing a handheld welder based solely on power is long gone. Handheld laser welding has continuously advanced—from early-generation assembled water-cooled models, to air-cooled units, and now to integrated refrigerant-cooled systems from leading brands. These advancements have ushered in the era of Handheld Welding 4.0.

A refrigerant-cooled handheld laser welder with just 900W of power can now rival the welding performance of a 1500W assembled water-cooled model. STRONGEST LASER is at the forefront of this new generation, proving that it’s not just about power—it’s about smarter, more efficient technology.

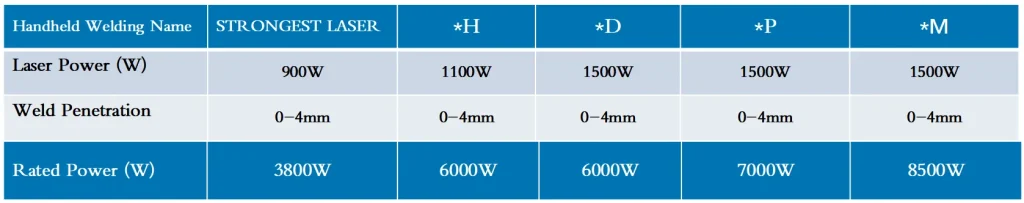

(Figure 1:Handheld laser welding machine product parameters)

The handheld laser welding market is currently flooded with a wide range of products. Aside from laser power, price is one of the top concerns for users. Many end up choosing lower-priced machines just to save a couple thousand yuan, only to fall into hidden cost traps they didn’t anticipate.

Laser power doesn’t just affect welding penetration—it’s also directly linked to input power consumption (see Figure 1). As shown, even when welding the same 4mm thickness, differences in laser power can lead to drastic variations in the input power required by different types of handheld welders.

Based on the conversion formula between input power and electricity cost, a handheld welder with higher input power will inevitably lead to higher electricity expenses over time.

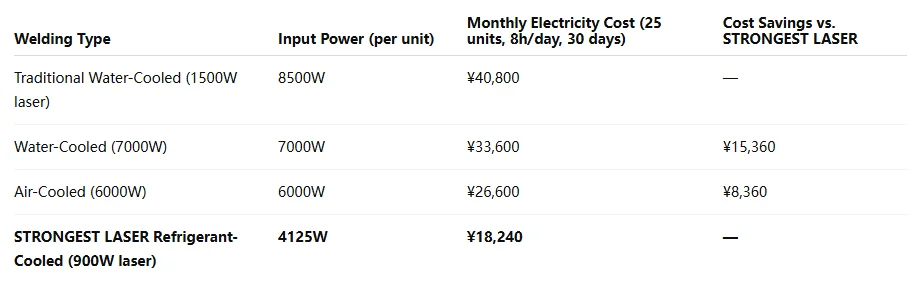

Take, for example, a 1500W assembled water-cooled handheld laser welder. Using its input power as a reference and assuming full-power output, we can calculate the electricity cost associated with using this machine for production. This gives a clearer picture of the long-term operational costs that often go overlooked when focusing solely on the initial purchase price.

With an input power of 8500W, let’s assume the factory operates 8 hours per day and uses a total of 25 handheld welding machines. Given that electricity rates vary by region and time, we’ll use an average electricity cost of approximately ¥0.8 per kilowatt-hour.such as 30 days of production and processing in January, the 1500W assembly of water-cooled hand-held welding for a month to produce electricity costs of ¥40,800.

According to the calculation,

the input power of 7000W water-cooled handheld welding, ¥33,600/month ;

input power of 6000W air-cooled handheld welding machine,¥26,600/month ,

while the STRONGEST LASER refrigerant handheld laser welding, ¥18,240/month.

Even when compared to the more energy-efficient air-cooled handheld welders, STRONGEST LASER’s refrigerant-cooled handheld welder can save business owners nearly 20% in electricity costs. And when compared to traditional water-cooled models, the savings soar to an impressive 60%.

Over just a few months of regular production, these energy savings can easily add up to the cost of an entire new machine—putting real money back in your pocket while improving efficiency at the same time.

(Electricity Cost Comparison – Same Weld Depth, Same Output, Different Handheld Welders)

After seeing this kind of cost analysis, would anyone still rush to buy a machine just to save a couple thousand yuan upfront?

From the very beginning of product design, STRONGEST LASER has focused on real user needs—thinking from the user’s perspective. We’ve not only continuously improved performance and welding quality, but also prioritized energy efficiency and environmental responsibility.

On one hand, this helps users significantly reduce electricity costs. On the other, it supports the national call for energy conservation and emissions reduction. By embedding a strong sense of social responsibility into our R&D process, STRONGEST LASER is actively contributing to sustainable development—one weld at a time.