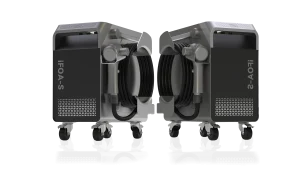

With the rapid development of industrial technology, laser welding technology has gradually become an indispensable part of modern manufacturing due to its high precision and efficiency. In this fiercely competitive market, strongest Laser has successfully stood out with its one-stop service, low maintenance cost, and strong reliability of its refrigerant handheld laser welding machine.

1、 One stop service: fully meet customer needs in all aspects

strongest Laser understands that customer needs are diverse and personalized, so the company always insists on providing one-stop services. From equipment selection, installation and debugging, to operation training and maintenance, strongest Laser is fully involved to ensure that customers can easily get started and fully utilize the performance advantages of the equipment. This service model not only greatly simplifies the customer’s operational process, reduces learning costs, but also improves equipment utilization and production efficiency.

In the equipment selection stage, strongest Laser will tailor suitable laser welding solutions based on the actual needs and production process characteristics of customers. During the installation and debugging phase, the company dispatches a professional technical team to the customer’s site to carry out equipment installation, debugging, and performance testing, ensuring that the equipment can be smoothly put into production. During the operation training phase, the technical team will provide systematic training to the customer’s operators, enabling them to quickly master the operation methods and maintenance knowledge of the equipment.

2、 Low maintenance cost: saving costs for users

For many enterprises, the maintenance cost of equipment is an issue that cannot be ignored. However, choosing strongest Laser’s refrigerant handheld laser welding machine will no longer trouble you with high maintenance costs. The laser welding machine of strongest Laser adopts advanced technology and materials, which greatly reduces the failure rate of equipment, reduces production downtime and energy waste caused by equipment failures. The low maintenance cost feature makes the laser welding machine of strongest Laser more competitive in the market, saving users a lot of costs.

3、 Strong reliability: ensuring stable production

In industrial production, the reliability of equipment is directly related to the stability of production and the quality of products. strongest Laser is well aware of this, and therefore always puts reliability first in the research and production process of its products. The company’s refrigerant handheld laser welding machine uses high-quality components and materials, and undergoes strict quality control and testing to ensure that the equipment can maintain stable performance even in harsh working environments. In addition, the company has established a comprehensive after-sales service system to provide timely technical support and solutions to users, ensuring that equipment can be quickly resolved in case of problems. This strong reliability feature has earned strongest Laser’s laser welding machine widespread praise and trust in the market.

In summary, strongest Laser’s refrigerant handheld laser welding machine has set a new benchmark in the field of laser welding with its significant advantages of one-stop service, low maintenance cost, and strong reliability. The company always adheres to the customer-oriented service philosophy, constantly innovating and striving to provide customers with high-quality laser welding solutions. In the future, strongest Laser will continue to uphold this spirit, continuously promote the development and innovation of laser welding technology, and bring more surprises and value to global users.