Copper, known for its outstanding electrical and thermal conductivity, is widely applied in industries such as electronics, telecommunications, aerospace, automotive, and construction. As manufacturing demands continue to grow, the use of handheld laser welding for copper has become a focal point in manufacturers’ promotions. However, with marketing jargon flooding the market, buyers seeking truly suitable handheld welders for copper must keep a sharp eye and make informed choices.

Selecting the appropriate handheld welder begins with a clear understanding of the inherent difficulties in welding copper.

1. Difficulty in Material Fusion

Copper’s high thermal conductivity causes heat to dissipate rapidly from the weld zone, resulting in a wide heat-affected area across the entire workpiece. This makes it challenging to achieve proper material fusion during welding.

2. Susceptibility to Deformation

Due to copper’s high coefficient of thermal expansion, excessive heat during the welding process can easily lead to material deformation. This places high demands on the welder’s skill and precision.

3. Prone to Porosity

During copper welding, the presence of hydrogen and oxidation-reduction reactions can easily lead to porosity. This issue becomes even more pronounced in deep penetration welding processes.

4. High Laser Reflectivity

At room temperature, copper has a very low absorption rate for near-infrared laser wavelengths. As a result, a significant portion of the incident laser is reflected during welding, leading to severe energy loss, low laser energy utilization, increased wear on optical components, and ultimately, a shorter service life for handheld laser welders.

STRION LASER’s STR-HW Series handheld welders are designed with customer needs at the core. In response to the key challenges of copper welding, the series offers customized solutions tailored to real-world applications. Today, STR-HW products have been widely adopted across various manufacturing sectors, earning continued recognition from clients both at home and abroad.

(Copper welding effect)

During commissioning and use by end customers, the STR-HW series has demonstrated outstanding performance in copper welding.

Copper is characterized by rapid heat conduction and high reflectivity. Laser energy density and resistance to high levels of reflected energy are critical factors in copper welding. The STR-HW series handheld welders feature an integrated machine design, with a unique all-in-one welding gun that offers exceptional resistance to back-reflected laser energy. This enables continuous welding of highly reflective materials without overheating or downtime.

(STR-K20 welding Torch)

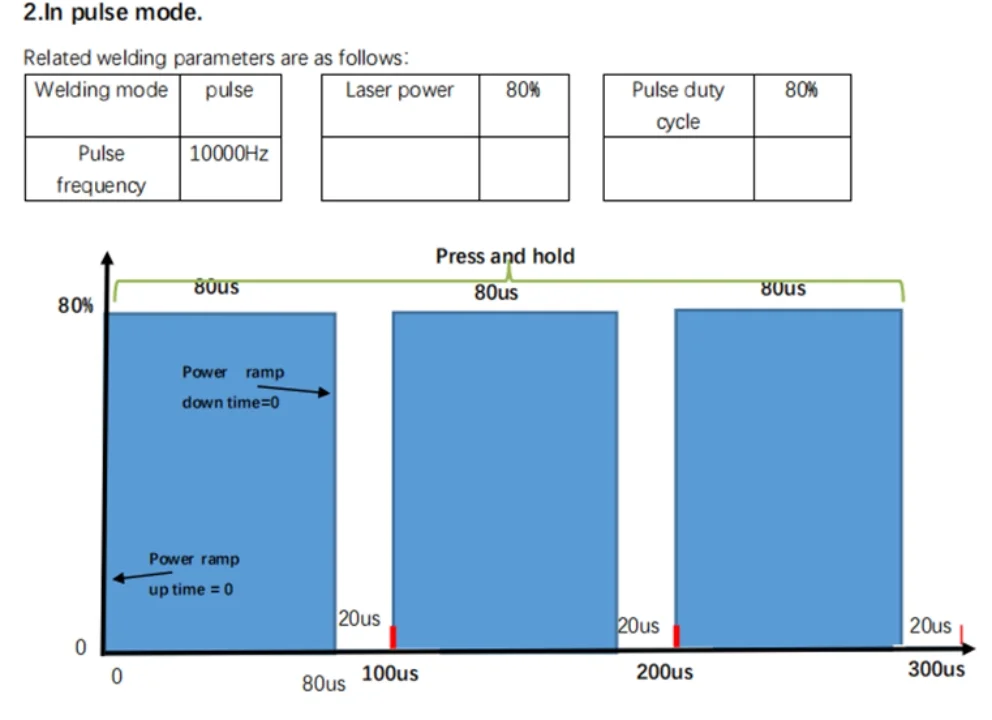

Copper has a high coefficient of thermal expansion and excellent thermal conductivity. Continuous welding can cause the laser temperature to rise excessively, leading to workpiece deformation. This not only increases welding difficulty but also directly impacts weld quality. The STR-HW series handheld laser welding machines offer a variety of welding modes, including a pulse welding mode with a maximum welding frequency of up to 50 kHz. In this high-frequency welding mode, the small laser spot can penetrate copper to form a weld seam while minimizing the heat-affected zone.

(pulse welding mode)

Porosity suppression during copper welding primarily relies on increasing laser energy density while reducing overall heat input. The STR-HW series handheld welders adopt advanced 14μm “small core diameter” technology, delivering a laser spot size of less than 40μm. This results in a laser energy density up to 300% higher than that of conventional laser welding machines. Even without oscillation welding, it can effectively reduce porosity, making it a powerful tool for copper welding applications.

(14μm small core diameter)

STRION LASER continuously drives technological innovation and research, actively engaging with real customer scenarios and gathering user feedback. By focusing on the true challenges and pain points faced by end users, the company transforms laser technology into practical applications. Through innovation and technical excellence, STRION LASER creates product value and delivers truly effective solutions, building a distinctive competitive edge unique to its brand.