In production environments, the continuous operating time of welding tools has a direct impact on overall efficiency. As one of the most sought-after welding devices in recent years, handheld laser welders have significantly boosted manufacturing productivity while also reducing the workload for operators. However, a major shortcoming that persists across many brands is the limited continuous welding time. Due to the nature of laser technology, effectively managing laser energy emission and reception, as well as optimizing the cooling of supporting components, has become a critical challenge—especially in the development of compact and lightweight equipment.

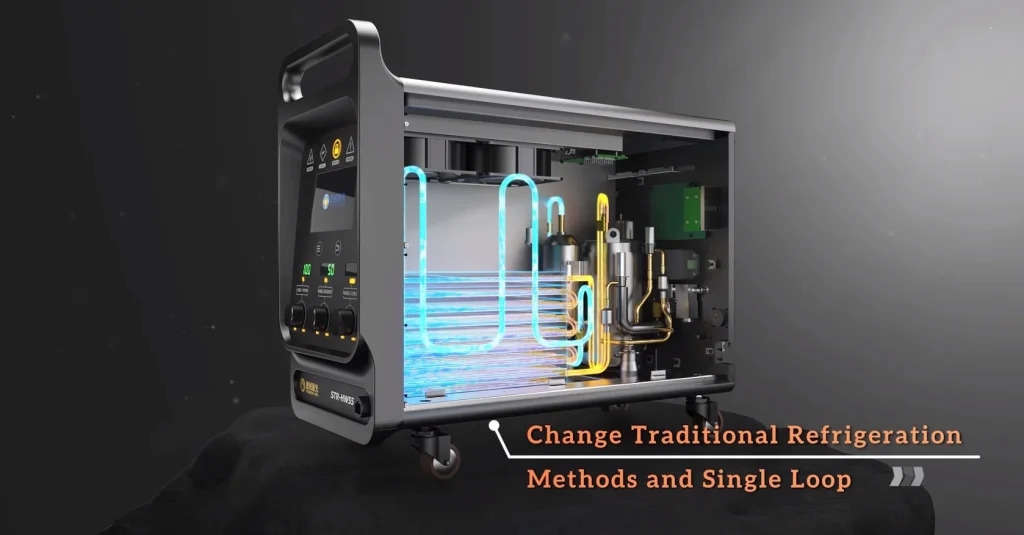

1.Dual-Circuit Coolant Intelligent Thermostatic System

The dual-circuit coolant system with intelligent temperature regulation owes its efficiency to a uniquely engineered cooling design. Combining dual-loop cooling modes with smart control algorithms, it enables rapid internal heat dissipation for long-running welders. This system effectively adapts to sudden power fluctuations, ensuring optimal laser operating temperatures and stable beam output, while significantly enhancing the welder’s long-term operational stability.

2.Optimized Optical Path Design Minimizes Energy Loss

STRONGEST LASER’s patented technology features collimated optical path output within the welding torch, significantly reducing light loss from refraction and dispersion. This design ensures enhanced beam focus and stability, even during prolonged use. As a result, the welding torch handle remains cool in various working environments, improving the user experience while extending the torch’s lifespan and enhancing operational safety during continuous welding tasks.

3.Integrated Structural Design for Enhanced Reliability

The truly integrated design of the system is reflected not only in its highly compact internal architecture, but also in the optimized layout of fiber spooling and laser output from the welding torch. This comprehensive integration improves photoelectric conversion efficiency beyond that of most comparable welders on the market. The robust structural design ensures stable 24/7 operation, making the welder highly reliable for continuous industrial use.

4.Powerful Laser Core for Superior Efficiency

The STR-HW Series handheld laser welder is equipped with a self-developed laser core, rigorously tested and validated over years of technical refinement. Widely recognized by global customers, this laser module significantly enhances the photoelectric conversion efficiency of the overall optical system while minimizing energy loss. As a result, the welder consumes less power during extended operation, enabling longer working time under the same power conditions.

Strength is the True Measure!

The STR-HW Series handheld laser welder is equipped with a self-developed laser core, rigorously tested and validated over years of technical refinement. Widely recognized by global customers, this laser module significantly enhances the photoelectric conversion efficiency of the overall optical system while minimizing energy loss. As a result, the welder consumes less power during extended operation, enabling longer working time under the same power conditions.

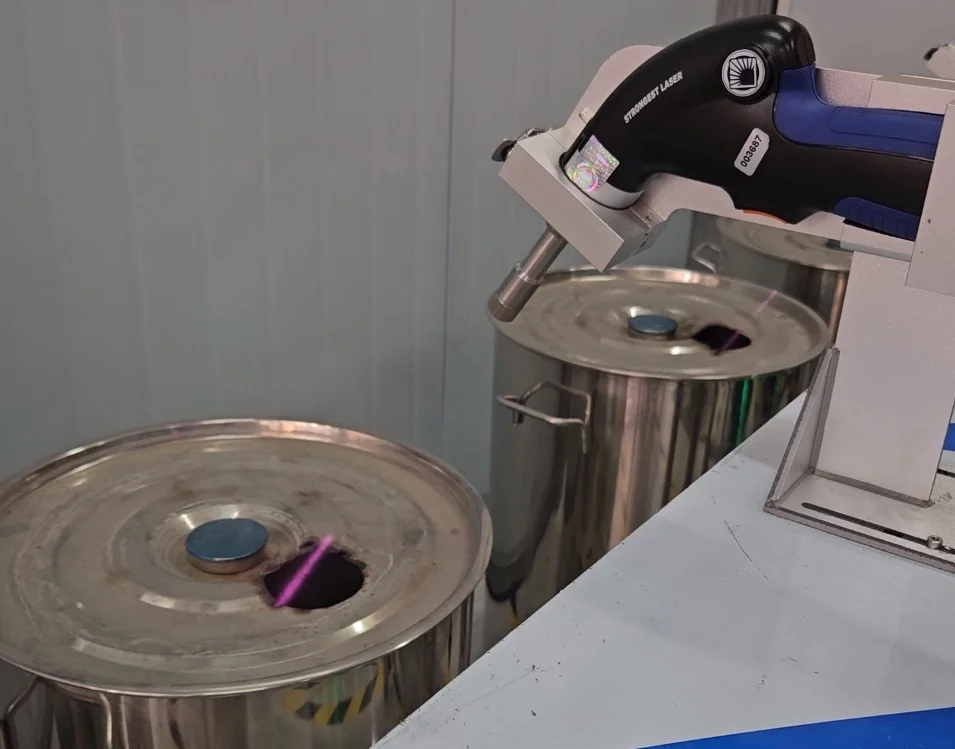

A total of 15 prototype units—covering all models of the STR-HW Series—underwent continuous outdoor testing for six months. During this period, the STRONGEST LASER STR-HW Series handheld laser welders successfully completed 28 rounds of 24-hour continuous laser emission tests and 20 rounds of 7×24-hour continuous laser emission tests.

In each test, the emitted laser beam continuously heated water inside a container. By monitoring the welder’s operational status and periodically measuring water temperature changes, the test team was able to verify whether the laser was functioning correctly. Additionally, the temperature of both the welder and the welding torch was checked every 30–40 minutes to analyze heat variation and assess thermal stability.

While testing the stability of laser output, we simultaneously monitored the temperature of the welding gun handle. The results showed that continuous laser emission by the STR-HW Series handheld laser welder did not cause internal overheating of the welding gun. Instead, the internal temperature of the gun varied in accordance with ambient environmental conditions, ensuring that the handle remained comfortably cool during operation.

Thanks to the powerful intelligent cooling system and the professionally engineered internal structures of both the welder and the welding gun, the STR-HW Series stands out as an advanced solution in the handheld laser welding field—especially in terms of extended welding duration. It demonstrates outstanding long-term operation capability, stable laser output, and minimal power attenuation over time.