Laser welding in thin plate processing in the application of more and more widely, whether it is a breakthrough in technical bottlenecks, or plate thickness, have made great progress and development. In recent years small portable, air-cooled, refrigerant has become the laser handheld welding industry wind hot words, every time a manufacturer to push the envelope, novel technical descriptions, a variety of marketing methods also dazzle the majority of users. Handheld welding in thin plate welding, because it is very reflective of the product in the welding process of the technical content. The application of thin plate welding has gradually become a “soldier must fight”, a variety of marketing and publicity calibre endless.

Understand handheld laser thin plate welding

(thin plate welding)

STR-HW series handheld welding machine is always committed to stand in the customer’s point of view, for the customer put forward the thin plate welding application difficulties, to provide customised solutions. At present, this series of products, to achieve continuous mode of 0.5mm welding without worry, pulse mode breakthrough to 0.2mm welding process limit.

We found that for thin plate welding, the main technical bottleneck of handheld welding is still the “stable” word of the product.

Welding Power – Steady

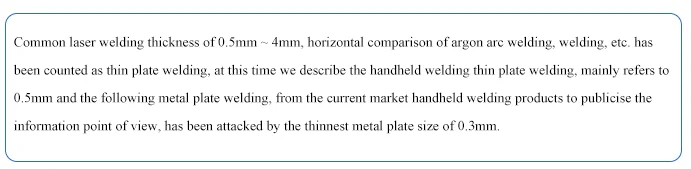

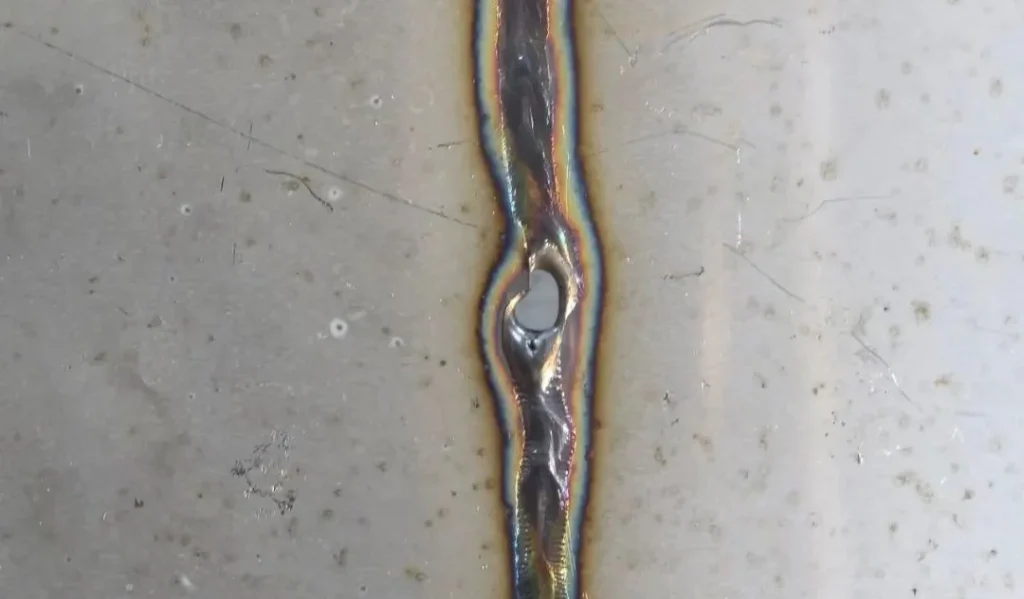

0.5mm below the thickness of the plate in the welding, vulnerable to the stability of the handheld welding power, laser power instability, in the regular plate thickness welding may not have much impact, but in thin plate welding, the first direct impact on the quality of the weld seam, the second so that the plate is more likely to melt through.

Thin plate welding process is difficult to overcome, in the final analysis, is the stability of the power output fails to reach the standard of precise control.

(Weld hole in the middle of the weld)

(Weld seam is big and small)

Some handheld soldering is constrained by cooling solutions, either by temperature variations or poor fit between assemblies, which can have a direct impact on the output power stability.

In what aspects does the STR-HW series achieve power stability?

Machine integration

The concept of whole-machine integration that has been adhered to since the early stages of research and development enables highly adaptive operation among optical, electrical, refrigeration, and welding gun components, ensuring high-quality, highly stable power output;

Self-developed dual-circuit refrigerant direct cooling

The self-developed patented dual-circuit refrigerant direct cooling system makes the equipment have good environmental adaptability. Even if it works 7*24 hours, high-efficiency refrigeration maintains the constant temperature of the equipment and makes the power output more stable;

Adaptive Repair Process Package

We are the first to use power adaptive repair technology and perform regular parameter corrections to ensure continued reliability during the life cycle and effectively avoid the impact of laser attenuation on power stability;

laser digitization

We have always integrated laser digital technology into the research and development of handheld welding to complement the last step of precise control of power output.

Welding process package Steady

Handheld welding products why the process package in the customer’s actual application, but also need to repeatedly debug the situation, in addition to the above mentioned laser power “instability”, the process package can only be re-adjusted. The more common reason is that the handheld welding directly take the market parameters of the existing process packages, not based on the customer’s actual application scenarios for verification and debugging, but also not with the handheld welding product itself for adaptation. At present, the effective attack on the thin plate welding process parameters are even less, and the standard level of different levels, levels, it is difficult to have a reference, not to mention welding good results.

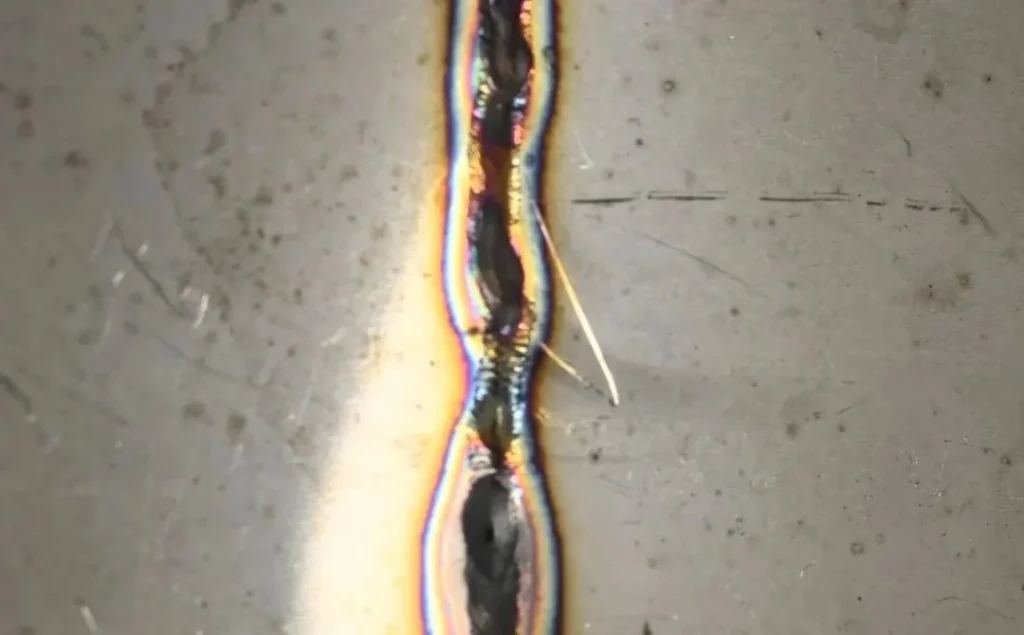

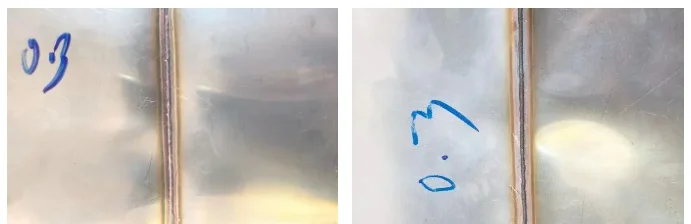

STR-HW series of products self-developed intelligent thin plate welding process package, in order to make the process package perfect to achieve the performance of the machine, STR laser from product development, welding technology, two-pronged approach, the early stage of research and development will set up a dedicated welding process team, consisting of a number of doctoral and master’s degree from the Harvard University of Technology and other prestigious schools specialising in welding, after more than 2 years of actual welding verification, in order to achieve the pursuit of the thin plate welding effect, many times to adjust, improve Process package parameters, and further upgrade the series of software control procedures, for 0.5mm, 0.3mm welding launched a special process package, the light out of the pendulum control is more delicate and practical, really let the technology out of the laboratory, effectively achieve the technology to meet the needs of industrialisation of thin plate welding.

In years of exploration, we have also deepened our understanding of hand-held welding products: no matter how much welding process development and adjustment is, it is empty talk when faced with the inability to accurately and stably control power output.

Wire Feeder Steady

Thin plate welding is very dependent on the welding speed, but the self-fusion welding can not be precise control of welding speed, welding operation by hand, fast and slow more likely to melt through the situation, so the thin plate can not be separated from the wire feeder for welding, and the thinner the plate, the higher the wire feeding speed, accuracy requirements.

At this time, the wire feeder as the core welding auxiliary tool, and the host of the integration of the degree of matching is very important. STR-HW series of handheld welding with STR-WF self-developed wire feeder, embedded in matching the performance of the host of the self-developed intelligent process package, the welding use of the full embodiment of the whole integration of the machine – with the matching, suitable, fit the advantages of the host, no need to repeat the debugging host and the parameters of the wire feeder. STR Laser is able to break through to the 0.2mm welding process limit in overcoming the difficulties of thin plate welding without its divine assistance.

Conclusion

The above analysis of the thin plate welding several major difficulties to overcome, but it should be noted that, unlike the welding of plates above 0.5mm, thin plate welding has a certain skill threshold, it is really difficult to achieve the novice easy to start, so you can not deliberately weaken the requirements of the welder, whether it is the fixed precision of the pre-weld assembly, or the welding in the proficiency of masters need to have a certain degree of welding experience to weld a good result. We should pay attention to the combination of product characteristics and the conditions of the company’s labour allocation, and carefully screen the purchase of products to avoid unnecessary cost losses.

Based on innovation and the pursuit of excellence, STRONGEST LASER is not satisfied and stagnant under the stage of products rapidly entering the market, and continues to penetrate into the customer’s scene, actively collects users’ feedbacks, and carries out product upgrade based on practical applications. We know that the greater the ability, the greater the responsibility, determined to benefit the market with the core technology, with the market to feed the industry innovation and development, the future will bring customers more practical, convenient handheld laser welding products.