Fiber laser technology has become a cornerstone of modern industrial applications, with small-core and large-core fiber lasers each offering distinct advantages depending on the specific requirements of the task. Understanding the differences between these two types of lasers—particularly in terms of power density, heat-affected zone, and weld surface quality—is crucial for optimizing performance in precision welding, surface treatment, and other manufacturing processes. This article provides a detailed comparison of small-core and large-core fiber lasers, highlighting their respective strengths and ideal use cases.

1.Power density:

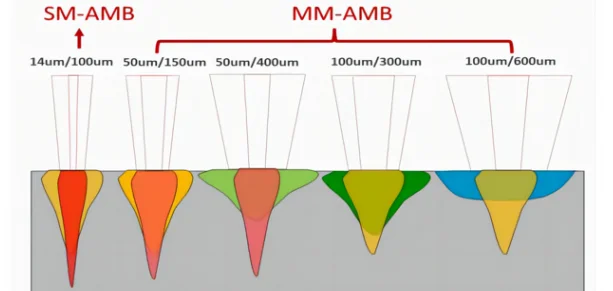

Small Core Lasers: At the same power, the power density of the small core diameter laser welding machine is high. For example,14μm.

Large Core Lasers: The large core diameter laser welding machine has a large light spot, more dispersed energy, and a small unit power density.

2.Heat-affected zone:

Small Core Lasers:Due to the concentrated energy, the small-core-diameter laser welding machine has a small heat-affected zone. It can accurately heat the welded parts, is suitable for materials and processes with strict requirements for the heat-affected zone, and can effectively control thermal deformation and thermal damage.

Large Core Lasers: During large-core diameter laser welding, the heat coverage area is large and the action area is wide, which will increase the melting width and the heat-affected zone will also be larger.

3.Weld surface quality:

Small Core Lasers:The small core diameter laser has a high probability of keyhole collapse during low-speed welding, and the keyhole closure period is long, which is easy to produce defects such as porosity, and the surface of the weld is relatively rough. However, the quality of the weld seam is improved at high speeds or with oscillating trajectories.

Large Core Lasers: The large core diameter laser has a large light spot, energy dispersion, and a relatively stable welding process, which is more suitable for laser surface remelting, cladding, annealing and other processes with high requirements for weld surface quality, which can make the surface of the material slightly melted and obtain better surface quality.

In conclusion, the choice between small-core and large-core fiber lasers depends largely on the specific demands of the application. Small-core lasers excel in high-precision tasks requiring concentrated energy and minimal heat-affected zones, while large-core lasers are better suited for processes prioritizing stability and superior surface quality. By carefully considering factors such as power density, thermal impact, and weld characteristics, manufacturers can select the most appropriate laser technology to achieve optimal results in their operations. As fiber laser technology continues to evolve, both small-core and large-core systems will play pivotal roles in advancing industrial manufacturing capabilities.