The 2025 “China Welding Industry Forum – Conference on Robotic and Intelligent Welding Technologies and Applications” was grandly opened in Jiaxing, Zhejiang. This forum gathered many leaders, experts, scholars, authoritative organizations, and leading enterprises in the welding industry, focusing on the frontier development and application of robotic and intelligent welding technologies, aiming to promote industrial upgrading and technological progress.

As an important participant in the global laser industry, STRION LASER was invited to attend. Yang Qingchun, Deputy Director of the Marketing Department, delivered a keynote speech titled “STRION LASER Robotic Welding System Integration and Engineering Application Cases.”

Deputy Director Yang Qingchun provided an in-depth analysis of the development history and future trends of the laser welding market, and officially released STRION LASER’s newly developed standardized robotic laser welding solution tailored for the era of automation.

He precisely outlined the development stages of laser welding technology:

“2018 marked the first year of large-scale application of handheld laser welding technology. By 2025, with major breakthroughs in robotic automation and standardization at the application level, laser welding technology is reaching a critical inflection point.”

This perspective highlights the urgent demand in global manufacturing for highly efficient, consistent, and flexible production methods, while underscoring the enormous potential of deep integration between laser welding technology and industrial robotics.

At this critical juncture, STRION LASER, leveraging its strong technological foundation and deep insight into industry pain points, has innovatively launched a standardized robotic laser welding solution designed to address the sector’s core challenges.

This solution systematically resolves key issues such as high integration complexity, long delivery cycles, and difficulties in long-term maintenance often encountered in robotic laser welding systems. Its core design philosophy lies in high standardization and modularization, ultimately delivering the core values of easy integration, easy delivery, and easy maintenance.The solution is composed of three major core modules:

High-Performance Self-Cooled Laser Source

1.Proven Reliability: Built on STRION LASER’s STR-HW series platform, ensuring stable and dependable performance.

2.Advanced Cooling: Proprietary dual-loop coolant system maintains stable operation in temperatures from -30°C to 60°C, supporting 7×24-hour continuous production.

3.Long-Term Power Stability: Delivers consistent output for up to 5,000 hours, guaranteeing uniform weld quality.

4.Wide Material Compatibility: Capable of welding materials from 0.3 mm to 7 mm, suitable for diverse industrial applications.

(Self-Cooled system)

Lightweight, high-performance wire feed assembly

1.Intelligent anti-collision: Equipped with a sensitive anti-collision system, it can quickly and automatically return to its position when encountering an unexpected collision, effectively protecting the torch head from damage.

2.Smooth Wire Feeding Experience: The optimized wire feed assembly ensures continuous, smooth wire delivery throughout the welding process, effectively preventing wire jams and breakage.

3.Precise and Rapid Positioning: Integrated with a red-line positioning device, it provides intuitive guidance for focal point measurement, significantly improving focus accuracy and efficiency while saving time and effort.

4.Lightweight and Agile Handling: The torch weighs only 4.2 kg, significantly reducing robot load, enabling more flexible and agile welding movements, and adapting easily to complex trajectories.

5.Wide Welding Coverage: The 140° large-angle flange connector provides the torch with an expanded range of motion and superior posture adjustment, enabling full weld access with no blind spots.

6.High Process Compatibility: Compatible with a wide range of welding process packages, effortlessly handling various materials, thicknesses, and welding requirements for versatile industrial applications.

(Push-pull wire feeding system)

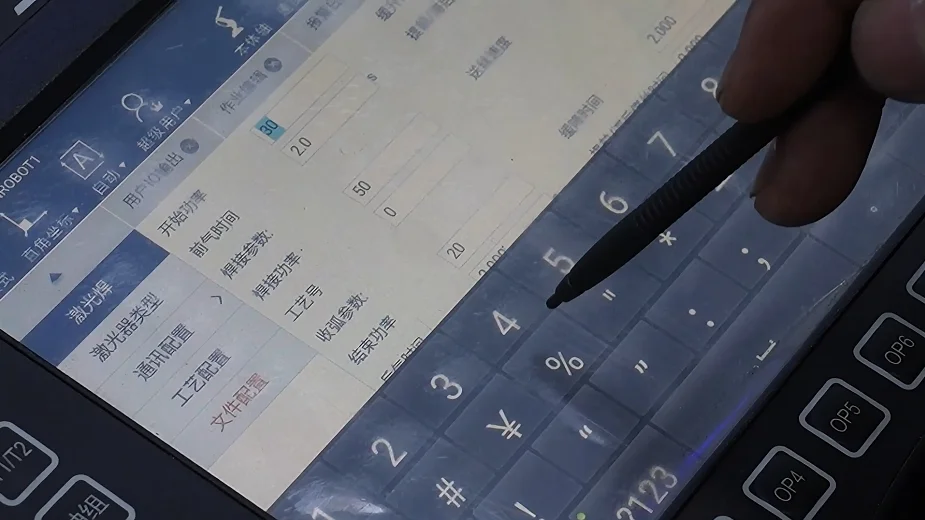

Intelligent robot master control system

1.Integrated Core Component Control: Innovative unified control of the laser source, welding torch, and other key components, streamlining operation and simplifying workflow.

2.Industrial Connectivity & Integration: Supports multiple mainstream industrial communication protocols and offers abundant expansion ports, ensuring seamless compatibility and efficient integration with various industrial robots and automation systems.

3.Preloaded Automated Welding Packages: Equipped with multiple rigorously validated welding process packages, significantly reducing user setup complexity and enabling out-of-the-box operation.

(Intelligent control system)

Strion Laser leverages its in-depth understanding of self-developed laser core performance and proprietary control system capabilities to achieve highly optimized integration between the master control system, laser source, and actuators. This system-level, bottom-up approach ensures optimal welding process performance, distinguishing Strion Laser’s solutions from simple component-assembled systems.