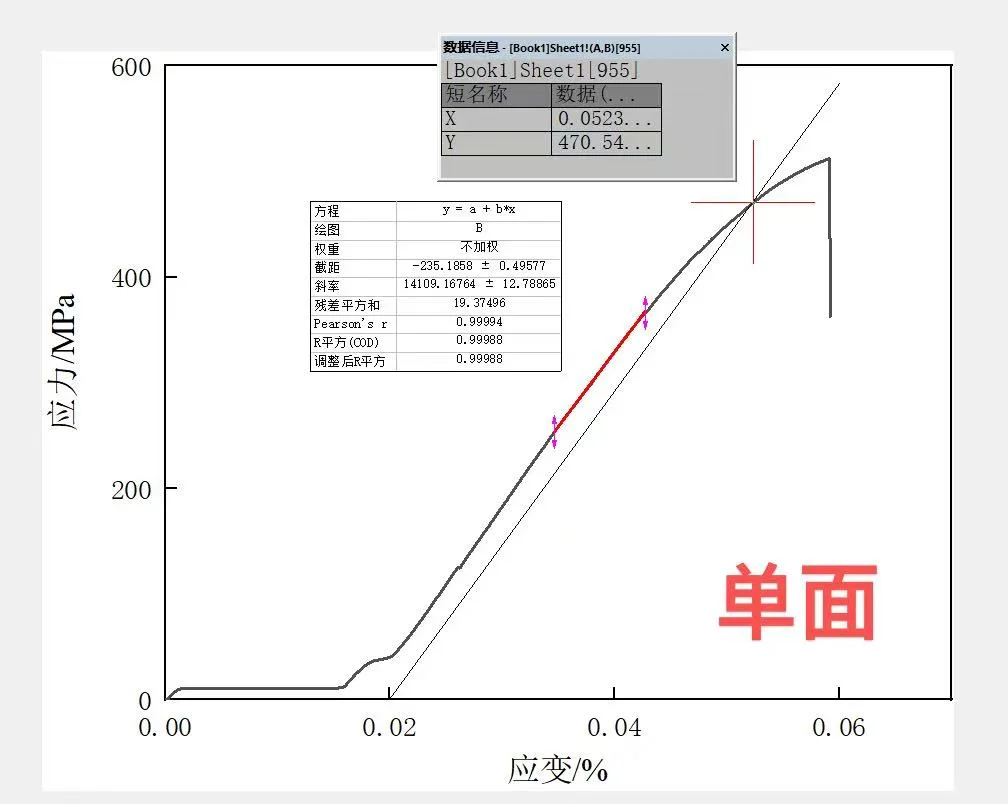

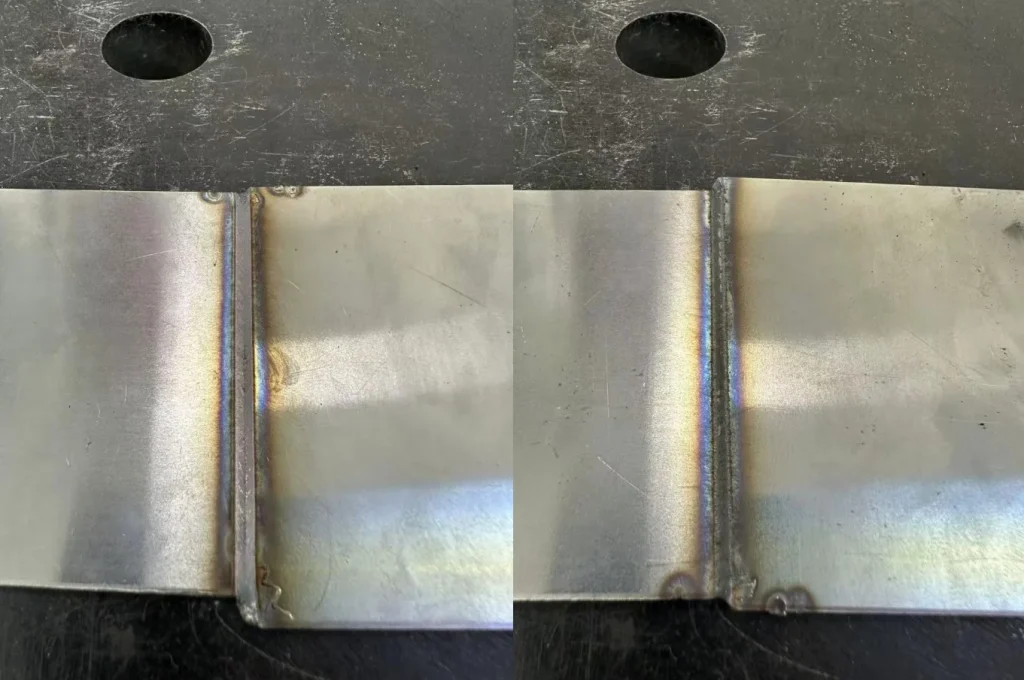

STRION LASER has successfully completed a tensile and weld strength verification test on 430 stainless steel using its advanced 1.8M Sinomach robotic welding system (Model: HW850), achieving an impressive tensile strength of 512MPa, well above the technical challenge benchmark of 400MPa.

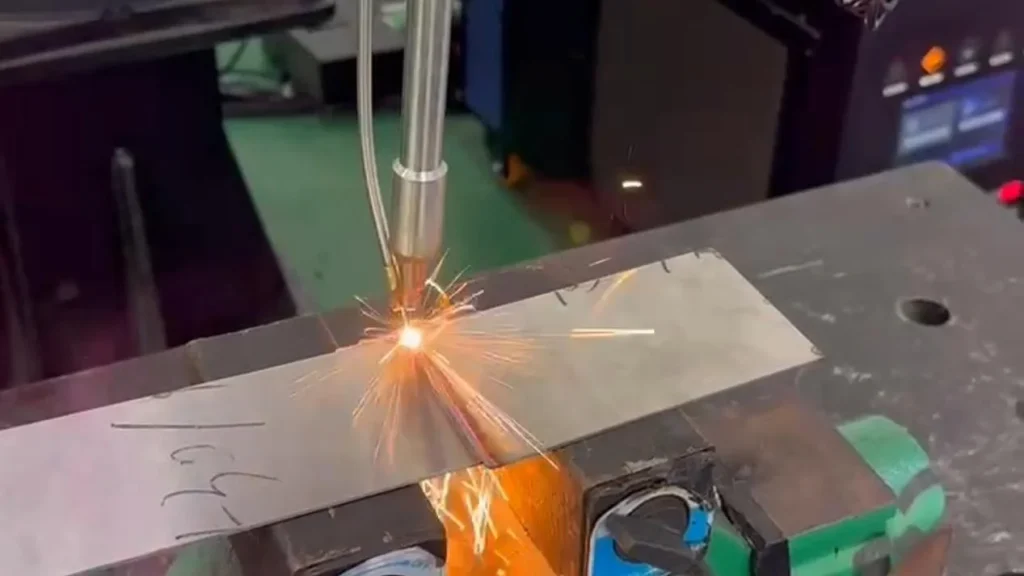

The test was performed using a 1.2mm 309L stainless steel wire in laser splicing weld mode. Welding parameters included a power setting of 31%, scanning speed of 400mm/s, wobble width of 3.0mm, wire feed speed of 50cm/min, and robot travel speed of 10mm/s. The process successfully demonstrated STRION LASER’s expertise in laser welding technology for high-strength applications.

Key Welding Techniques Ensuring Strength and Reliability:

1.Uniform Welding Speed

Maintains consistent weld bead geometry and enlarges contact area with the base metal, improving overall joint integrity and tensile resistance.

2.Effective Shielding Gas Protection

Reduces oxidation during welding, resulting in cleaner, higher-quality weld seams.

3.Consistent Wire Feeding

Guarantees stable filler deposition and controlled fusion of materials.

4.Full Penetration Welding

Ensures that weld metal completely fuses with the base material, forming a continuous metallic structure across the joint section.

5.Avoiding Overwelding

Excessive power or slow travel speed can lead to brittle welds or hot cracking. Optimized parameters help prevent these issues and maintain mechanical performance.

6.Prevention of Undercut Defects

Minimizing undercut maintains the contact area and prevents reduction in tensile strength at the weld edge.

This successful test not only proves the weldability of 430 stainless steel with 309L filler using STRION’s robot laser welding equipment but also highlights the company’s commitment to precision engineering, process control, and high-performance welding solutions for the industrial manufacturing sector.

For further information or collaboration opportunities, please contact STRION LASER at: