STR-HW SERIES LASER WELDING EQUIPMENT

Redefine the Performance of Laser Welding

STR-HW Series Handheld Fiber Laser Welding Machine

All metals can be welded

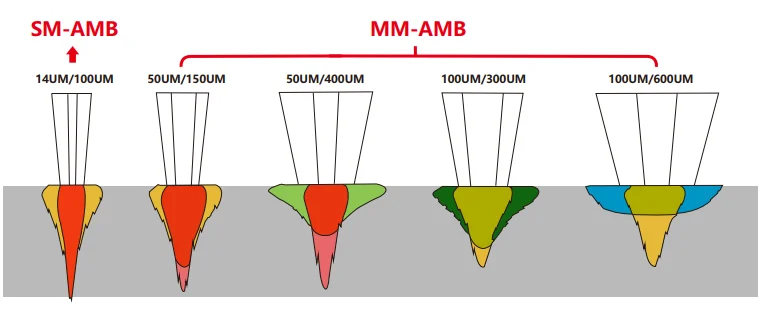

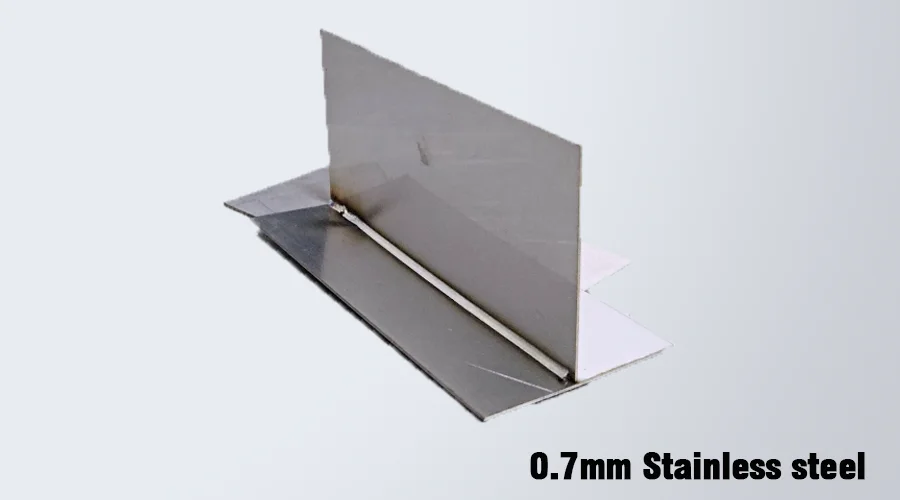

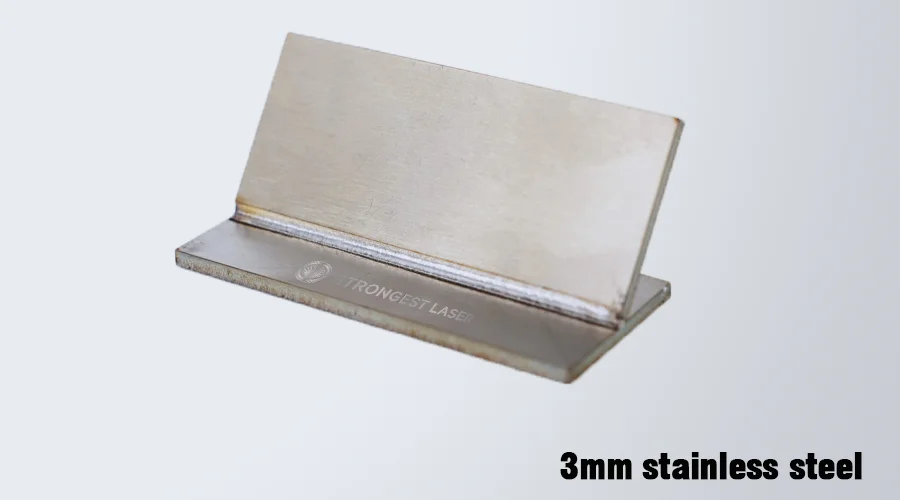

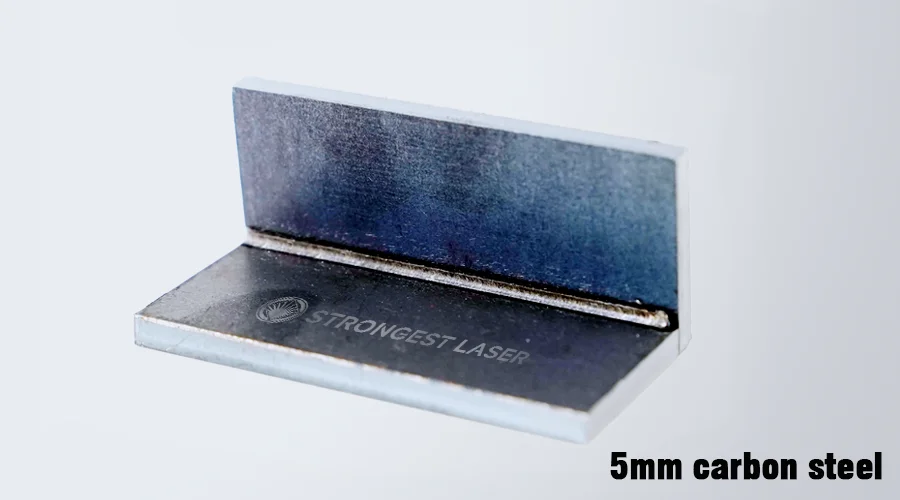

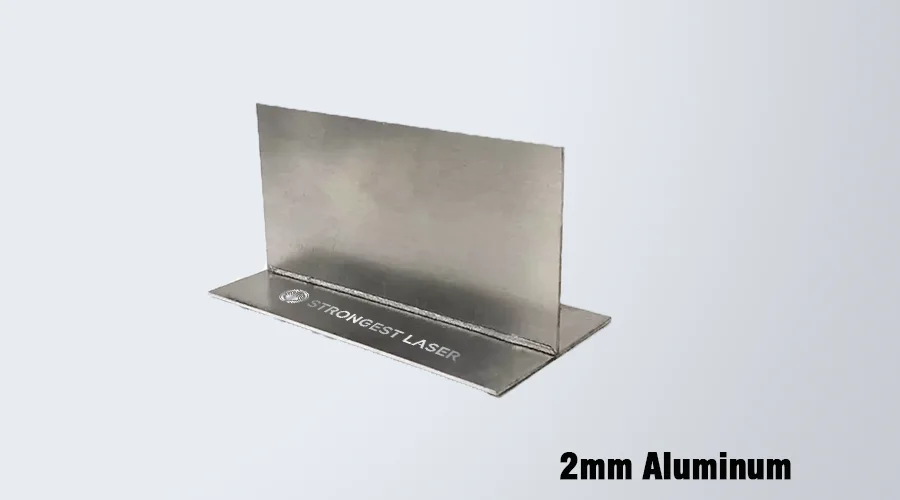

The STR-HW series handheld laser welding machines from STRION LASER laser welding manufacturer feature advanced “small core diameter” laser technology, a dual-circuit refrigerant cooling system, and an integrated design. Whether you choose the 700w handheld welding machine, the more powerful 900w handheld welding machine, or the high-capacity 1500w handheld laser welder, the STR-HW series provides a high-performance laser welding solution that ensures efficiency, deep penetration, energy savings, and stable operation. Versatile and reliable, these laser welding machines deliver excellent results on aluminum, stainless steel, carbon steel, galvanized sheet, brass, and more.

STR-HW Series - UNIQUE TO US BETTER THAN ALL

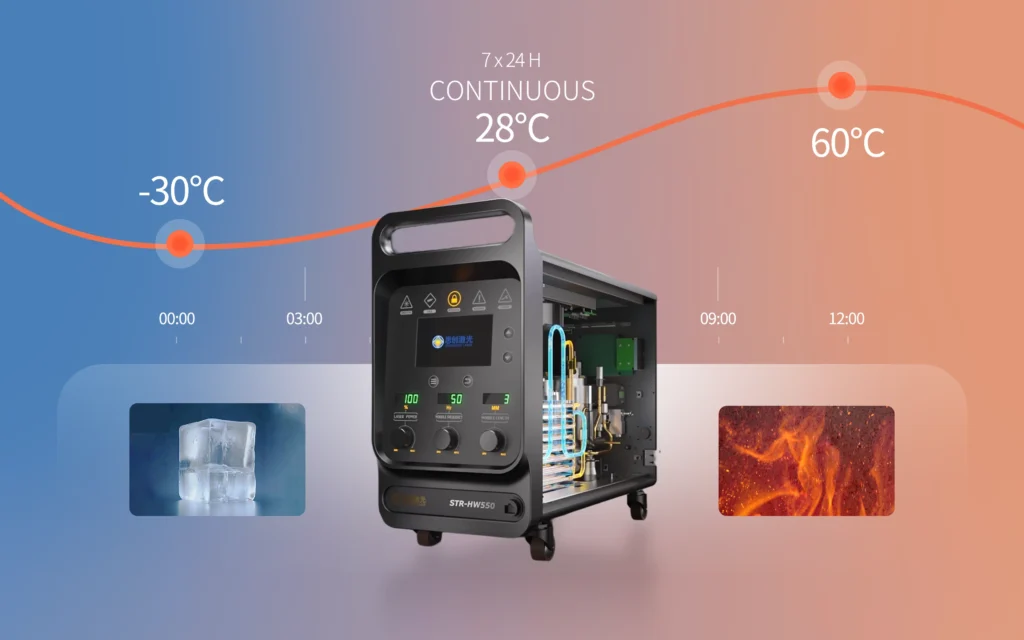

- Dual-circuit refrigerant system — 24/7 stable laser welding from -30°C to 60°C

- Self-repairing power, 5000 hours without attenuation

- Superior stability, long-term power fluctuation <1%

- 50% less energy consumption to any other welding method

Compact and portable STR-HW laser welding machine — 60% smaller and 1/3 the weight of conventional water-cooled machines.

STR-HW Series -3 IN 1 welding | cutting | cleaning

World’s first 3000W full-power laser cleaning machine — 6 output modes, 300×300mm scanning range.

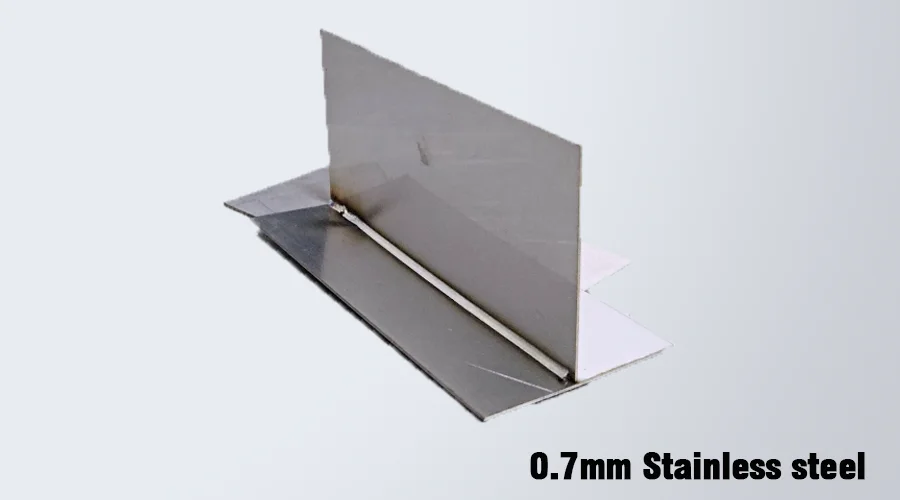

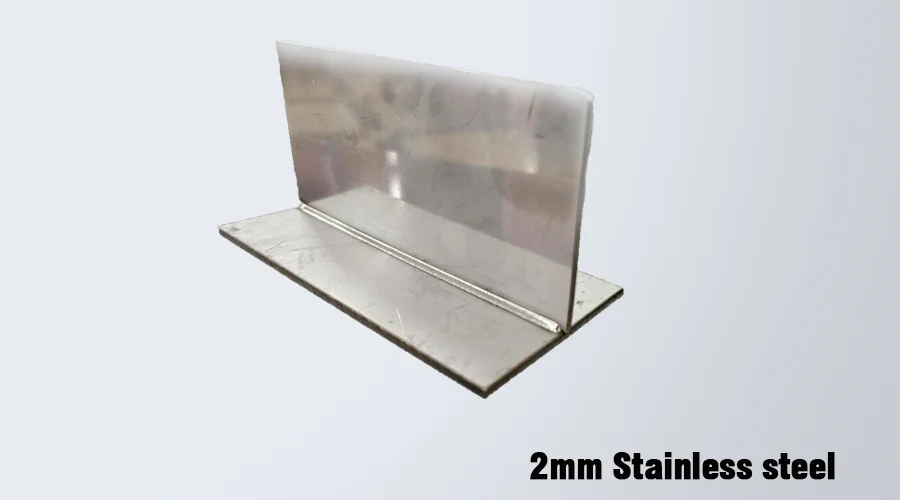

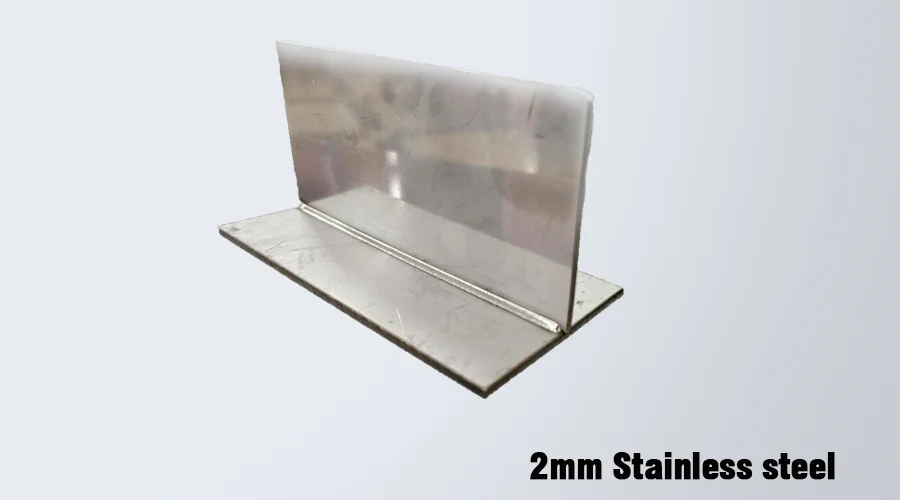

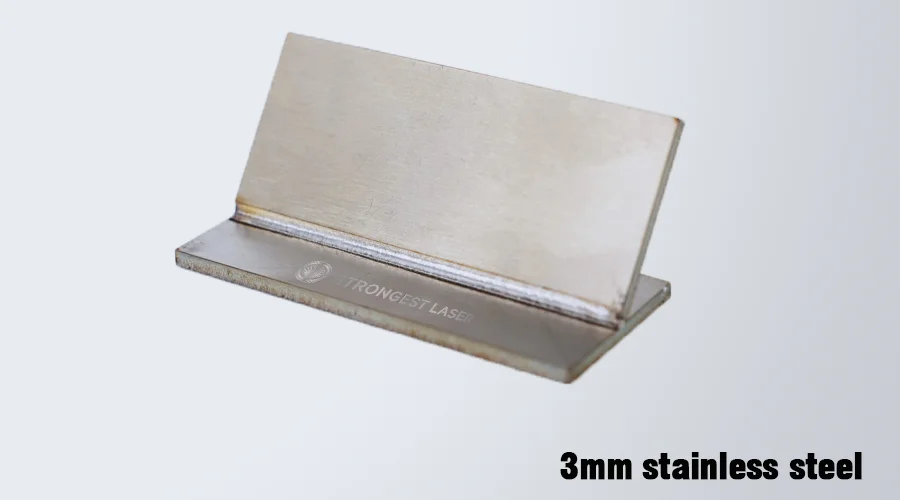

- Maximum 10 mm laser welding depth on stainless steel and steel

- Completes cutting tasks for various complex work scenarios in a short period of time and improves productivity.

Product Parameters

Product Parameters

Items |

STR-HW200 welding and cutting |

STR-HW350 welding and cutting |

STR-HW450 welding and cutting |

STR-HW550 welding and cutting |

STR-HW850 Welding, cutting, cleaning |

Rated input power supply | Single phase220V | Single phase220V | Single phase220V | Single phase220V | Three phase380V |

Input power frequency | 50/60Hz | 50/60Hz | 50/60Hz | 50/60Hz | 50/60Hz |

Laser power | 700W | 900W | 1200W | 1500W | 3000W |

Rated input power | 3200W | 3800W | 4200W | 5400W | 10500W |

Welding speed | 20~200cm/min | 20~200cm/min | 20~200cm/min | 20~200cm/min | 20~250cm/min |

Working temperature | -30℃~60℃ | -20℃~60℃ | -20℃~60℃ | -20℃~60℃ | -30℃~60℃ |

Working humidity | 0-90% | 0-90% | 0-90% | 0-90% | 0-90% |

Product dimensions | 675mm×310mm×580mm | 675mm×310mm×580mm | 673mm×310mm×605mm | 673mm×310mm×605mm | 863mm×410mm×724mm |

Product weight | 38kg | 39kg | 43kg | 45kg | 70kg |

Armored cable length | 5m/10m/15m/20m(Customizable) | 5m/10m/15m/20m(Customizable) | 5m/10m/15m(Customizable) | 5m/10m(Customizable) | 5m/10m(Customizable) |

Pre set process package | 16 | 24 | 30 | 40 | 50 |

Output mode | Integrated armored cable+welding torch | ||||

Applicable wire diameter | 0.8mm/1.0mm/1.2mm/1.6mm/2.0mm | ||||

Cooling mode | Dual-circuit refrigerant direct cooling | ||||

Welding mode | Spot welding/Continuous spot welding/ Pulse welding/Continuous welding | ||||

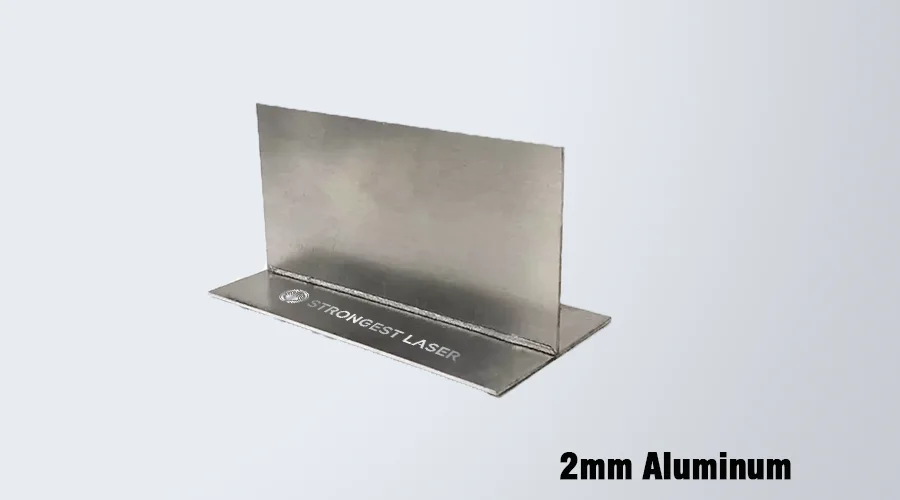

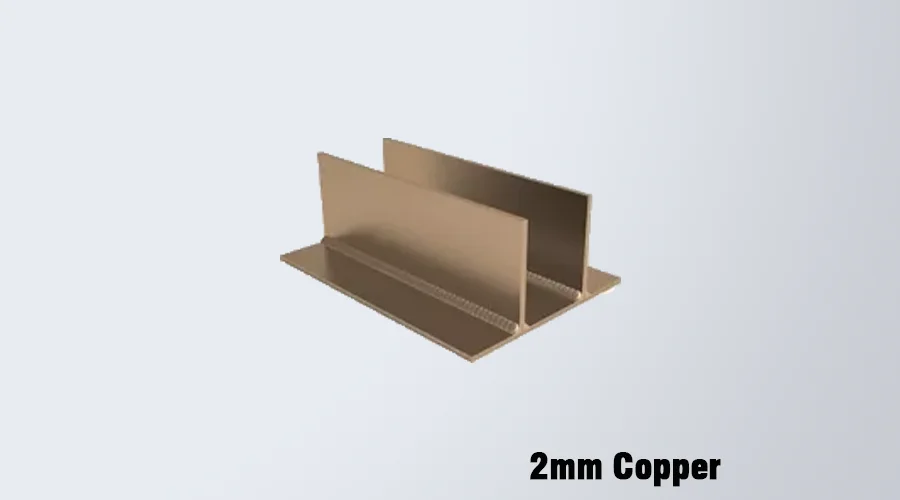

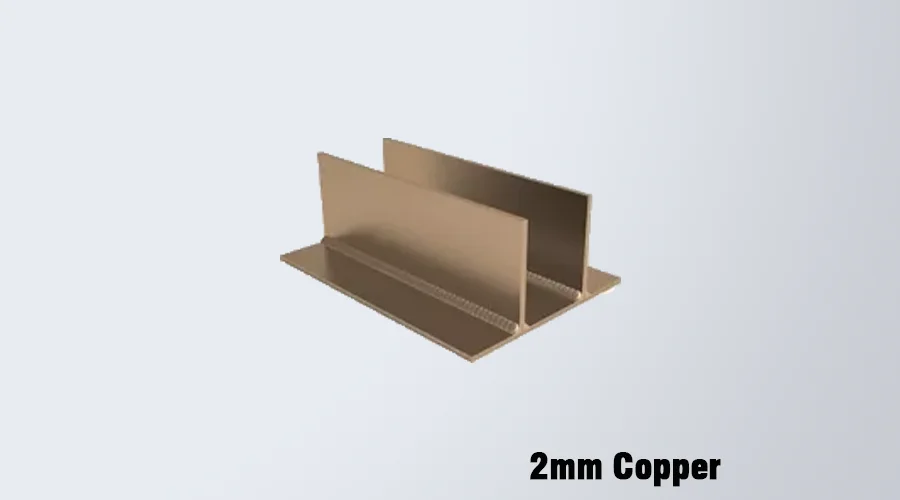

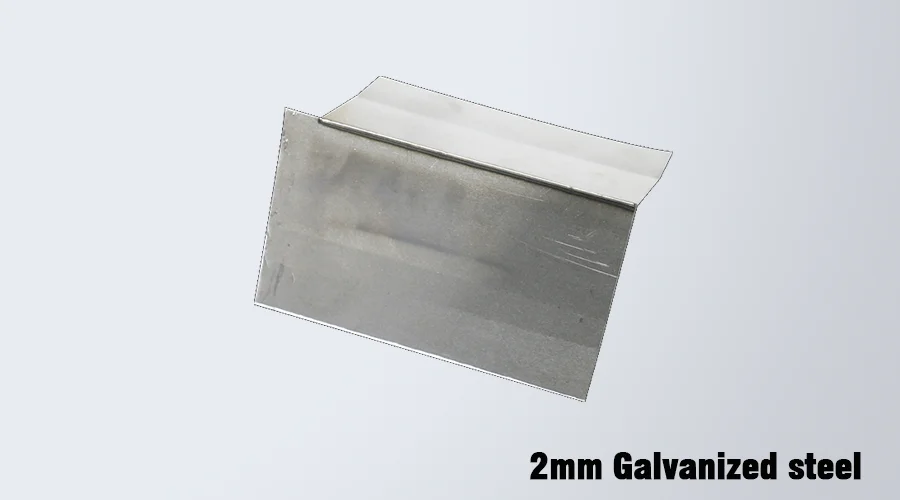

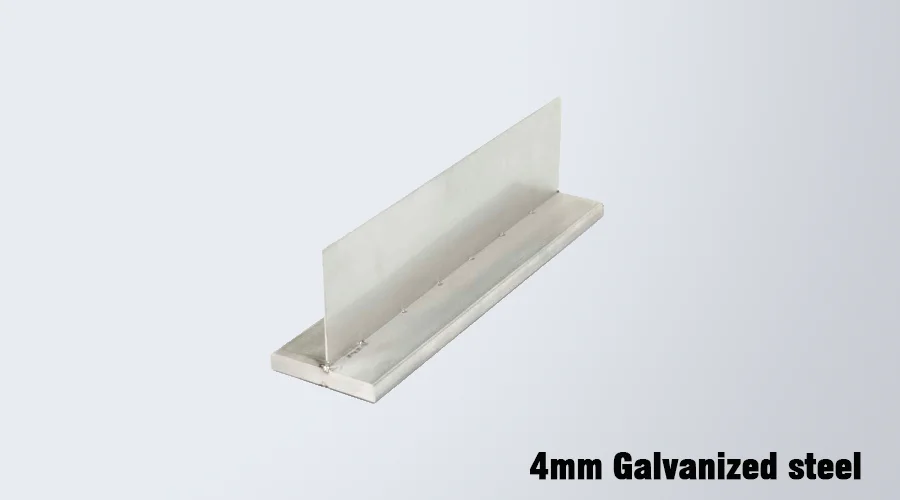

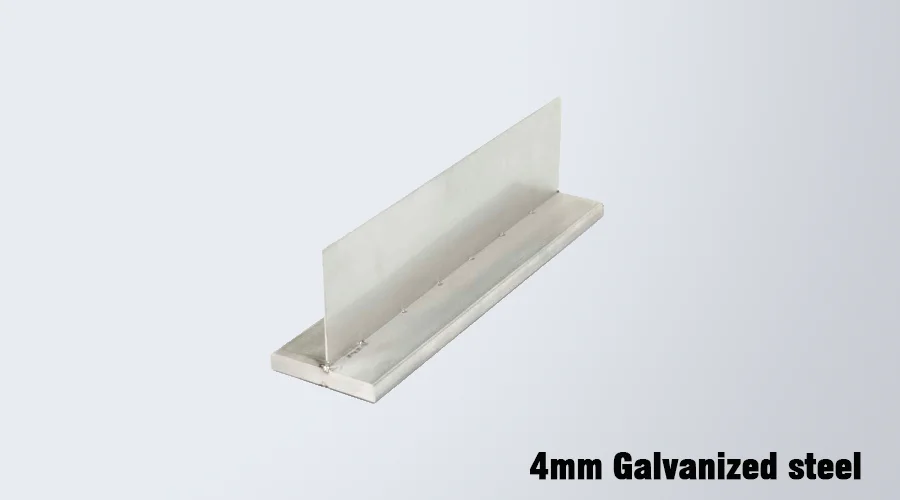

Aluminum | Stainless steel | Galvanized sheet | Carbon steel | |

STR-HW200 | 2mm | 2.5mm | 2.5mm | 2.5mm |

STR-HW350 | 3mm | 3mm | 3mm | 3mm |

STR-HW450 | 4mm | 4mm | 4mm | 4mm |

STR-HW550 | 6mm | 6mm | 6mm | 6mm |

STR-HW850 | 8mm | 10mm | 10mm | 10mm |

CLOSE

Product Core Benefits

Product Core Benefits

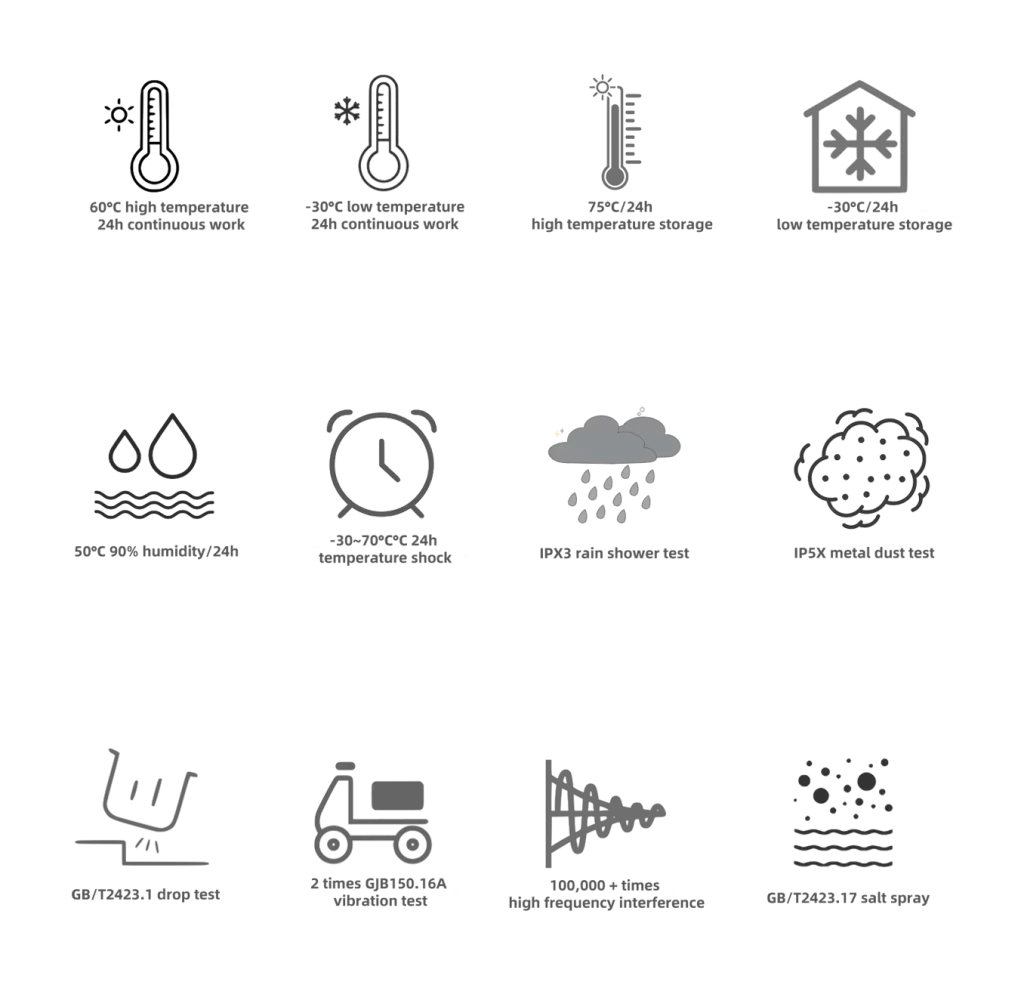

After rigorous testing it is durable and long-lasting

- Continuous working test at 60℃ for 24 hours

- 24-hour continuous operation test at 30℃ low temperature

- High temperature storage test at 75℃ for 24 hours

- Low temperature storage test at 30℃ for 24 hours

- 100000+ high-frequency interference tests

- -30~70℃ 24-hour temperature shock test

|

|

|

|

|

|

Unique design of welding torch, easy to operate and less malfunctioning

- By adopting a direct fiber optic collimation module input and a fully enclosed interface free design, the refraction and scattering losses of laser energy transmission between lenses are minimized to the greatest extent possible.

- The innovative handle is made of industrial plastic and soft rubber, greatly reducing the weight of the welding gun and providing better insulation performance.

CLOSE

Product Core Benefits

After rigorous testing it is durable and long-lasting

- Continuous working test at 60℃ for 24 hours

- 24-hour continuous operation test at 30℃ low temperature

- High temperature storage test at 75℃ for 24 hours

- Low temperature storage test at 30℃ for 24 hours

- 100000+ high-frequency interference tests

- -30~70℃ 24-hour temperature shock test

|

|

|

|

|

|

Unique design of welding torch, easy to operate and less malfunctioning

- By adopting a direct fiber optic collimation module input and a fully enclosed interface free design, the refraction and scattering losses of laser energy transmission between lenses are minimized to the greatest extent possible.

- The innovative handle is made of industrial plastic and soft rubber, greatly reducing the weight of the welding gun and providing better insulation performance.

CLOSE

What is STRION LASER? What is the traditional welding method?

What is STRION LASER? What is the traditional welding method?

An Innovation to Traditional Arc Welding Technology Effectively Improves Welding Efficiency

STRION LASER’s Handheld Laser Welding | Traditional Argon Arc Welding | |

| Welding effect | Beautiful welded joints | Post-processing grinding or polishing is needed for welded joints |

| Heterogeneous metal splicing | Yes | No |

| Workpiece deformation | Small | Large |

| Welding efficiency | It is 6-10 times the efficiency of argon arc welding | Energy is not concentrated and efficiency is wasted |

| Cost of use | Unskilled workers can operate, savign labor costs | High grade level welders required |

| Physical hazards | Low radiation, protective spectacles can filter out strong light | Great harm to welders and high incidence rate of occupational diseases |

| Environmental Pollution | Green and environmentally friendly | A large amount of smoke and dust pollution |

TIG Welding

TIG welding is time-consuming and requires skilled operators, generating high heat that can distort thin materials, reduce cosmetic quality, and limit welding of copper or metals with varying thicknesses. STRION laser welding machines overcome these issues with precision and efficiency.

STRION LASER

Compared with MIG or TIG, STRION laser welding machines use independent “small core diameter” laser welding technology with dual-circuit refrigerant cooling and integrated design, delivering higher efficiency, deeper penetration, energy savings, and easy operation.

MIG Welding

MIG welding requires consumable wire, material pre-cleaning, and beveled joints in thick metals to allow for complete penetration. Movement and working angles are limited, and vertical positions are challenging.

CLOSE

Independent research and development of wire feeder

Independent research and development of wire feeder

Items |

STR-WF00C |

STR-WF00B |

STR-WF00D | |

Wire feed tube length | 3m/5m | 3m/5m | 3m/5m | |

Compatible wire diameter | 0.8mm/1.0mm/1.2mm/1.6mm | 0.8mm/1.0mm/1.2mm/1.6mm | 1.0mm/1.2mm/1.6mm | |

Welding wire spool weight | 5kg/7.5kg/15kg/20kg | 5kg/7.5kg/15kg/20kg | 5kg/7.5kg/15kg/20kg | |

Wire feeder weight | 18kgs | 12kgs | 20kgs | |

Overall dimensions | 585mm×265mm×457mm | 510mmx290mmx425mm | 625mmx350mmx440mm | |

Maximum allowable wire spool diameter | 270mm | 300mm | 300mm | |

Wire feed mode | Single feed mode | Single feed mode | Double feed mode | |

Compatible wire materials | Stainless steel/Carbon steel/Aluminum alloy | |||

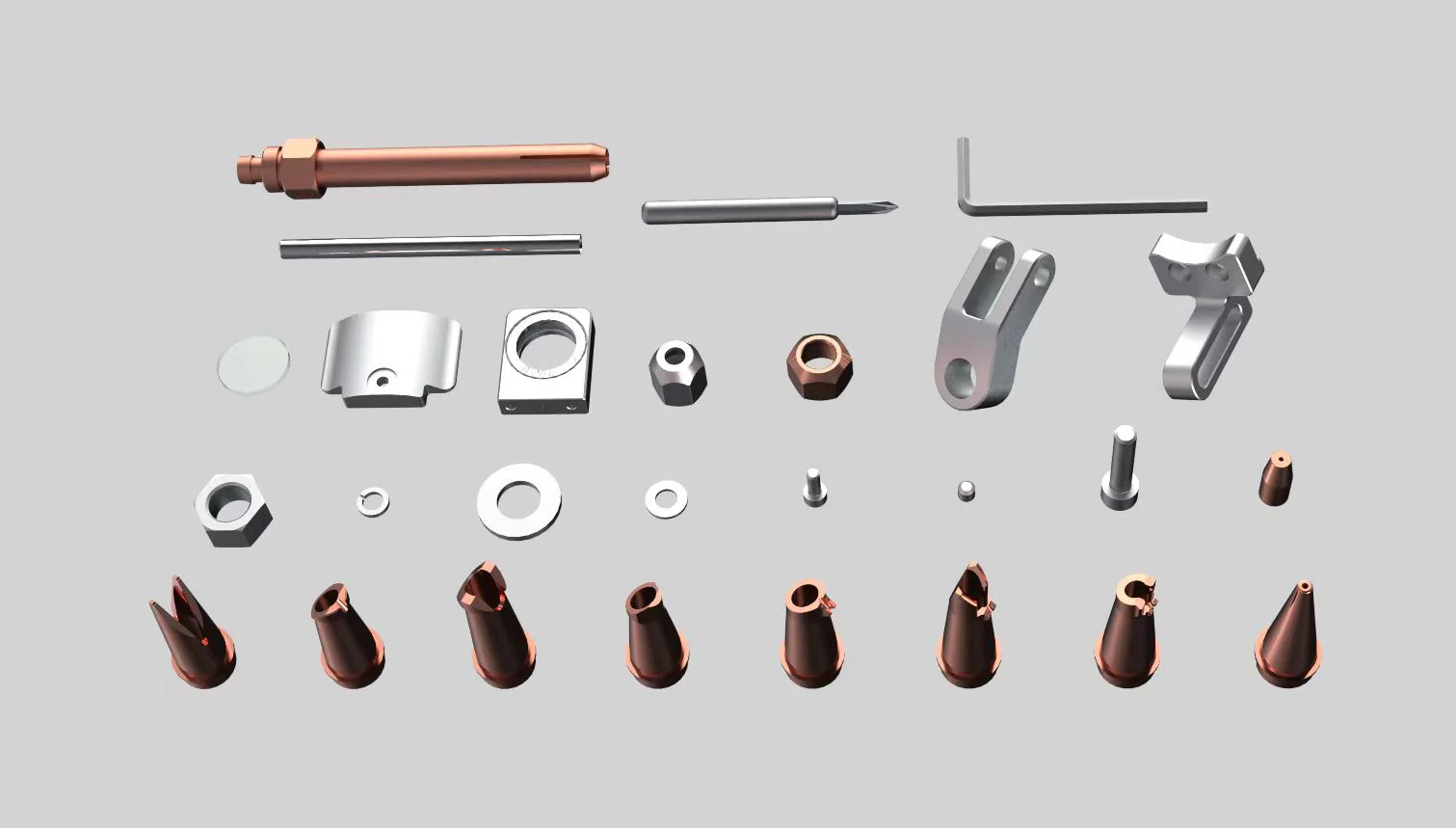

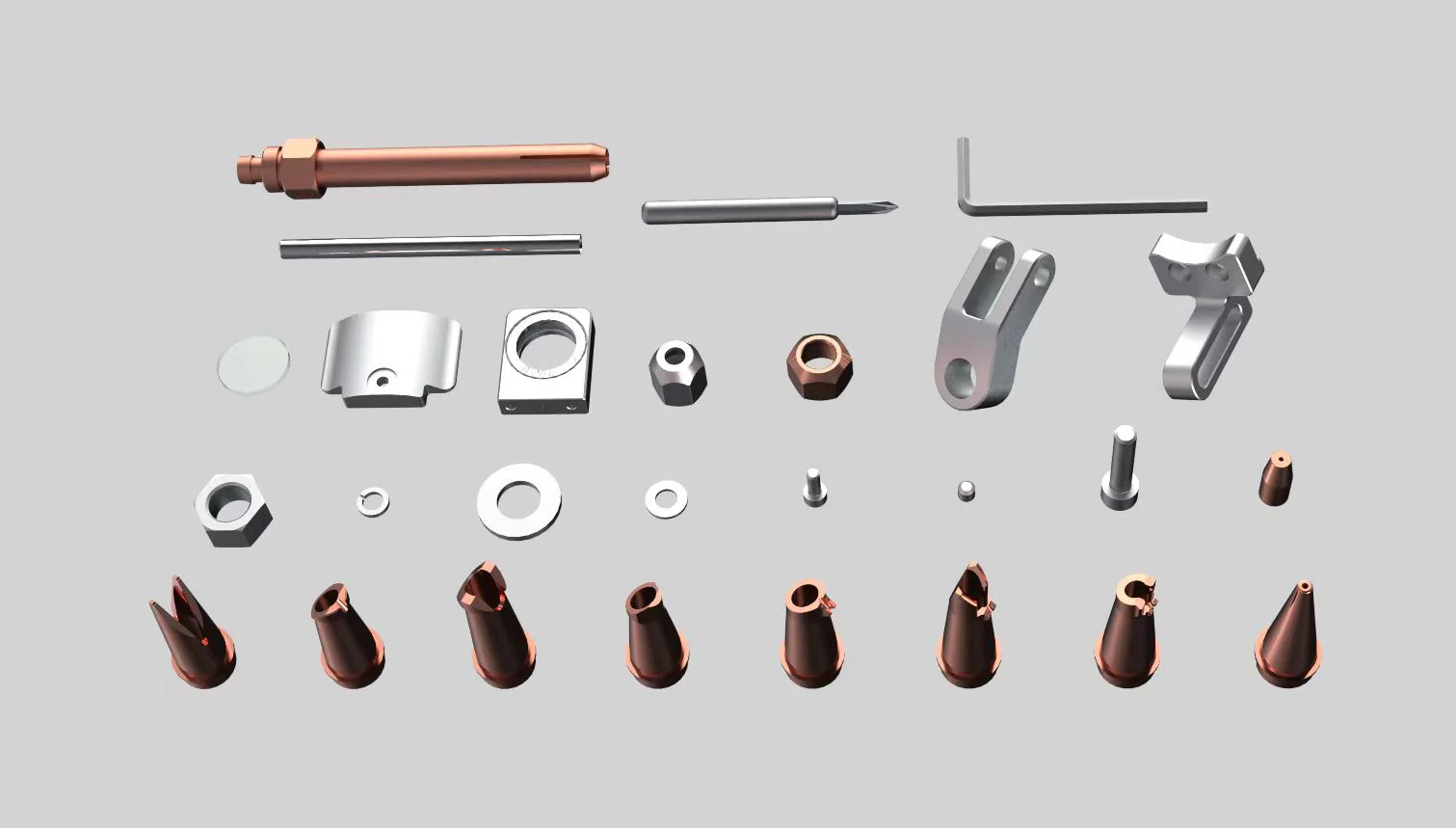

Components & Accessories

In order to facilitate customers to better use our handheld laser welding machine, STRION LASER will include a set of standard accessories, including (Protective Window/Focusing Lens/Copper nozzle and other perishable accessories). To learn more, please get in contact with us.

CLOSE

Applications

Applications

STRION LASER STR-HW series refrigerant handheld laser welding system has unique technology and performance in welding various metal materials such as aluminum, stainless steel, carbon steel, galvanized sheet, copper, etc. (special materials can be customized and developed).

CLOSE

Key Points of STRONGEST LASER’s Service Philosophy

Key Points of STRION LASER’s Service Philosophy

Customer First Philosophy

STRION LASER prioritizes customers in its service approach.

High-Quality Products

The company bases its service on delivering high-quality products.

Efficient After-Sales Service

Provides fast, responsive, accurate, and localized after-sales service through its dedicated system.

Closed-Loop Management

Implements a comprehensive process from acceptance to completion to enhance management efficiency and customer satisfaction.

CLOSE

Certifications and Achievements

Certifications and Achievements

Since its establishment, STRION LASER has built a strong reputation in the domestic laser field, excelling in technological innovation, product development, and market expansion. Its laser welding machines have earned ISO 9001, ISO 3834, CE certifications, and 95 intellectual property rights.

CLOSE

Become Our Distributor

Why become our distributor?

Benefit from our experts’ advice to meet your brand’s needs.

Product & Pricing Support

- High-performance laser welding equipment – including handheld, hybrid, and robotic systems

- Competitive distributor pricing – ensuring attractive profit margins.

- Customized product recommendations – tailored to different industry needs.

- Demo laser welding machine support – for marketing and customer demonstration

Marketing & Brand Empowerment

- Authorized use of our brand – legally use trademarks and branding materials.

- Exclusive territory protection – avoid price wars and protect your market.

- Exhibition and promotion support – marketing materials and event cost subsidies

- Joint promotion on our official website and social media – increase your local visibility

CLOSE

Frequently Asked Questions

Frequently Asked Questions

str-hw-series-laser-welding-equipment

Is the STRONGEST LASER really that easy to operate?

Of course, compared to MIG and TIG welding, both of which take a lot of time to master, the STRONGEST LASER is quick to learn and a new user can produce high-quality welds in just a few hours.

How much does the STRONGEST LASER handheld laser welding machine cost?

STRONGEST LASER has various models, please tell me more about your requirements such as the material to be welded, the thickness to be welded, etc. so that I can give you the best advice on the machine and price to recommend to you. You can contact our sales department.

Where are STRONGEST LASER machines produced?

STRONGEST LASER is located in Chengdu, Sichuan Province, China. It is one of the few manufacturers in the world that has the ability to independently develop laser sources. It currently has more than 15,000m² of R&D and production sites, equipped with complete technology R&D, product production, and application testing sites, including a 8,000m² optical cleanroom and a series of internationally advanced modern experimental instruments and equipment.

What kind of service system does STRONGEST LASER have?

On the one hand, we provide complete product installation teaching video in the early stage, which is systematic.

On the other hand, we have set up localized service sites in many countries, we will even provide technical training for you, and we will also provide some maintenance spare parts, such as copper, for free after bulk purchase.

What brand of laser source does STRONGEST LASER use?

STRONGEST LASER uses in-house developed laser sources. We are one of the few manufacturers in the world who are able to develop their own laser sources.

Can STRONGEST LASER weld dissimilar metals or parts with different thicknesses?

Yes, you can easily weld dissimilar metals like copper to stainless steel or to aluminum, plus parts with different thicknesses across all weld joint types: tee, butt, corner, lap and edge.

CLOSE