STRION LASER-Laser hybrid welding

Redefine the Performance of Laser Welding

STRION LASER-Laser hybrid welding

NON-FERROUS METAL WELDING EXPERTS

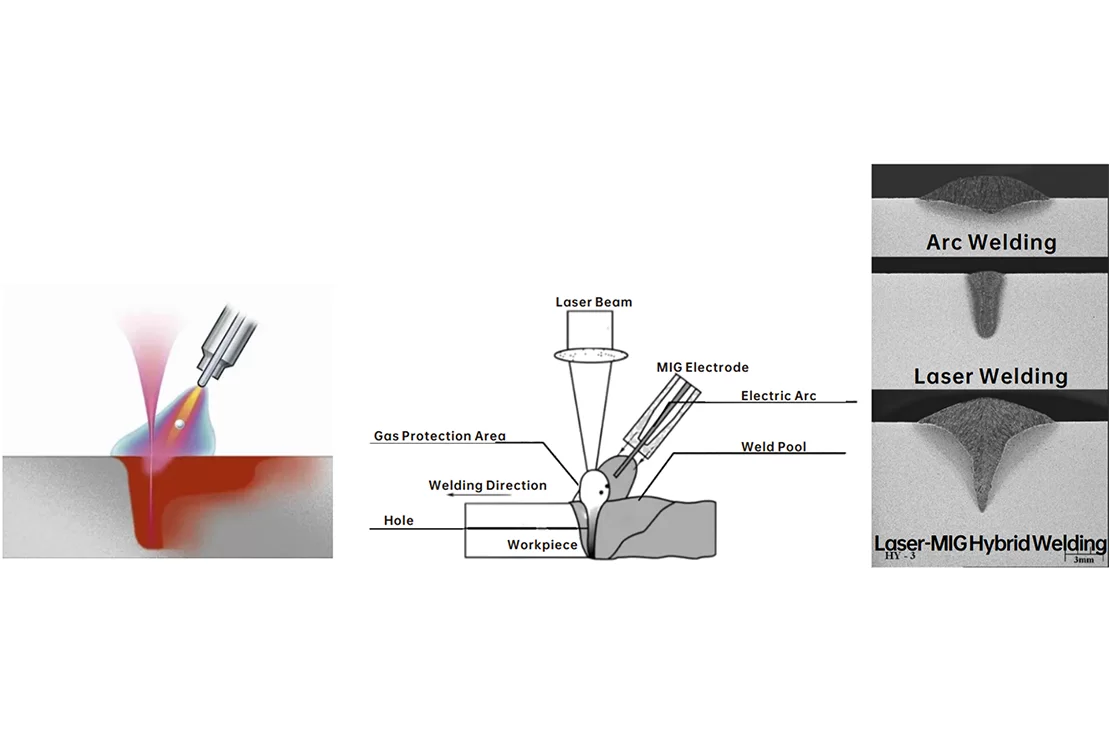

STRION LASER’s Laser hybrid welding combines the advantages of laser welding with those of arc welding. This welding process is becoming particularly established in shipbuilding, automotive production and rail vehicle construction.

STRION LASER- Red and Blue Laser Hybrid Welding

- Combining The Advantages Of Red And Blue Lasers For Wider Material Applications

- GreatlyIncrease The Absorption Rate Of Non-ferrous MetalsToImprove The Utilization Rate Of Laser Energy

- Normal Temperature Welding,Effectively Saving Materials

- Greatly Reduce The Welding Heat Effect To Meet The High-precision Welding Needs Of High-end Manufacturing

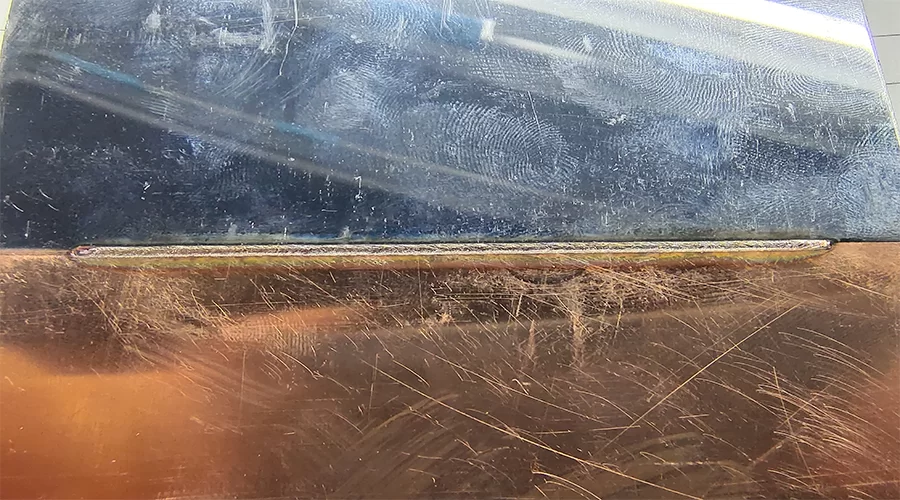

STRION LASER - Laser-MIG Hybrid Welding

- Powerful Combination of Laser Welding and Arc WeldingTechnology Reach Higher Penetration

- Faster Welding Speed to Improve Welding Efficiency

- Lower Unit Line Energy and Lower Welding Distortion

- Strong Weld Bridging, Insensitive Weld Gap,Wide Weldable Range

Laser-MIG Hybrid Welding

Laser-MIG Hybrid Welding

STRION LASER’s Laser-MIG hybrid welding technology is a welding method that combines laser and MIG welding to achieve efficient and high-quality welding by simultaneously utilising the high energy density of the laser and the filler material properties of MIG welding.

Laser and MIG 1+1>2 Welding Effects

- The plasma cloud generated by the laser and arc further absorbs and scatters the incident laser energy.

- By using the laser to generate the keyhole effect to attract,compress and stabilize the welding arc,the current density is significantly increased and a high-efficiency heat source is established.

- Arc guidance heats up the base metal and ncreases the absorption of laser energy,thereby increasing

.

| Technical parameters | ||

| Item | Parameters | Remarks |

| Laser power | 15kW | |

| Beam quality | 5mm-mrad | @100μm |

| Central wavelength | 1070nm | ±10nm |

| Modulation frequency | Max:20kHz | |

| Welding current(max) | 500A | DC Mode(No Pulse) |

| 400A | DCMode(With Pulse) | |

| Duty cycle | 100% | @Ambient temperature below45℃ |

| Optical platform scanning range | Max:12mm | |

| Optical platform scanning frequency | Max:500Hz | |

| Welding capacity(max) | Carbon Steel:20mm | Effective weldingquality |

| Welding head weight | 35kg | Standard configuration |

| Rated power consumption | Max:55kW | |

CLOSE

Red and Blue Laser Hybrid Welding

Red and Blue Laser Hybrid Welding

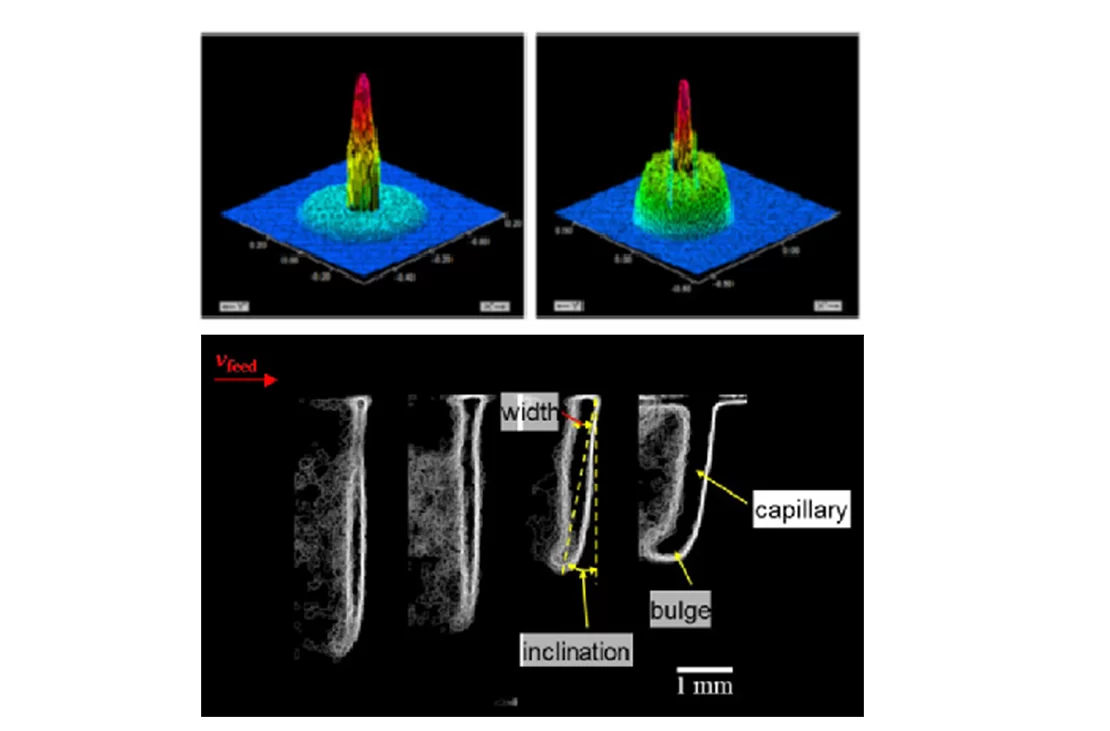

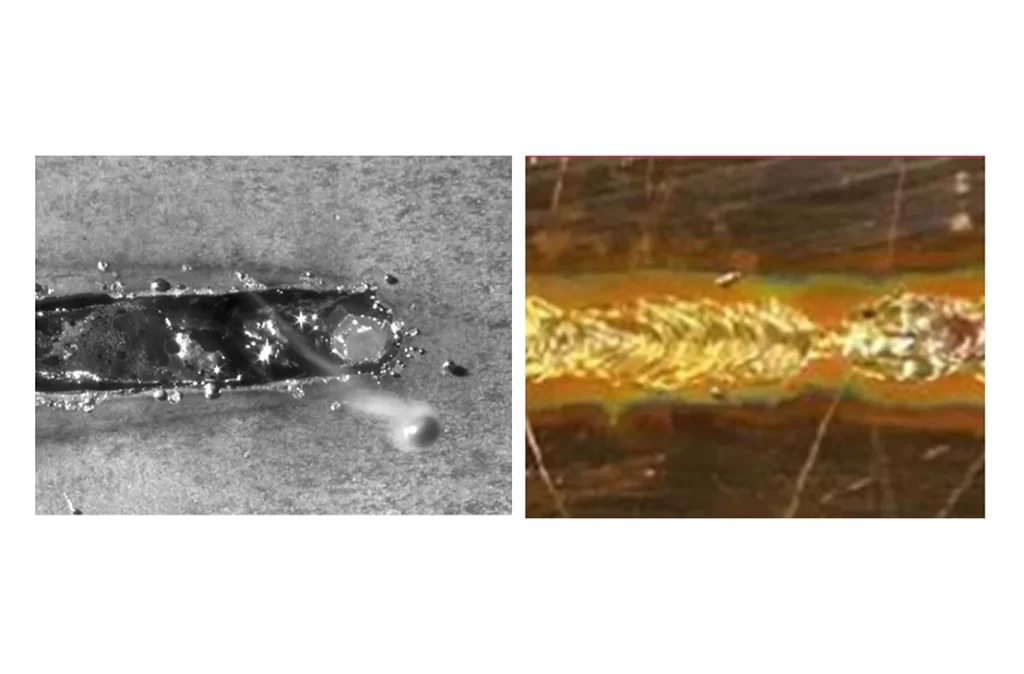

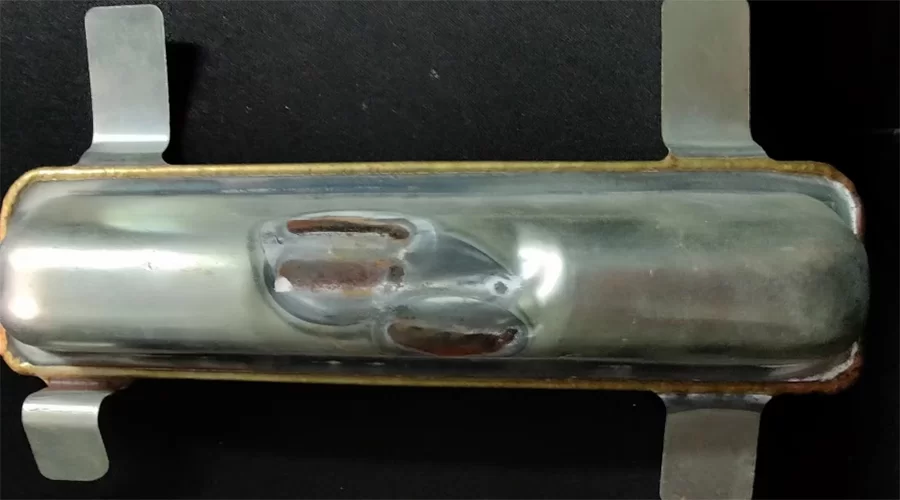

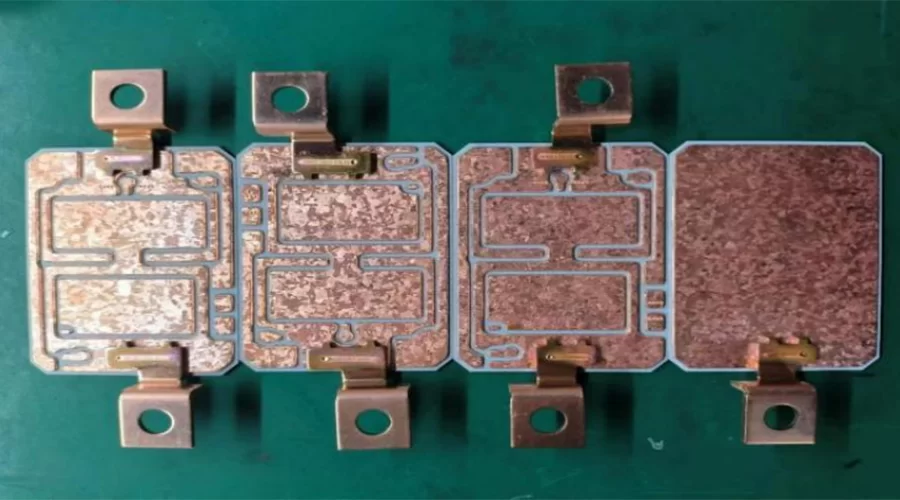

Blue-red hybrid laser welding process, through the blue laser’s high absorption rate of preheating the material, so as to achieve the absorption rate of the red laser rise, at the same time due to the blue laser’s power density compared with the fibre optic laser is small, can be achieved by combining the stabilisation of heat conduction welding and deep melting welding, to achieve the highly efficient welding of high anti-alloys (aluminium, copper).

Red and blue laser hybrid welding reduces spatter,porosity and improves weld seam forming

- Low brightness,high absorption blue light substrate heating, surface melt pool formation.

- Red and blue laser hybridlight field with enhanced infrared absorption(3X).

- Arc guidance heats up the base metal and ncreases the absorption of laser energy,thereby increasing.

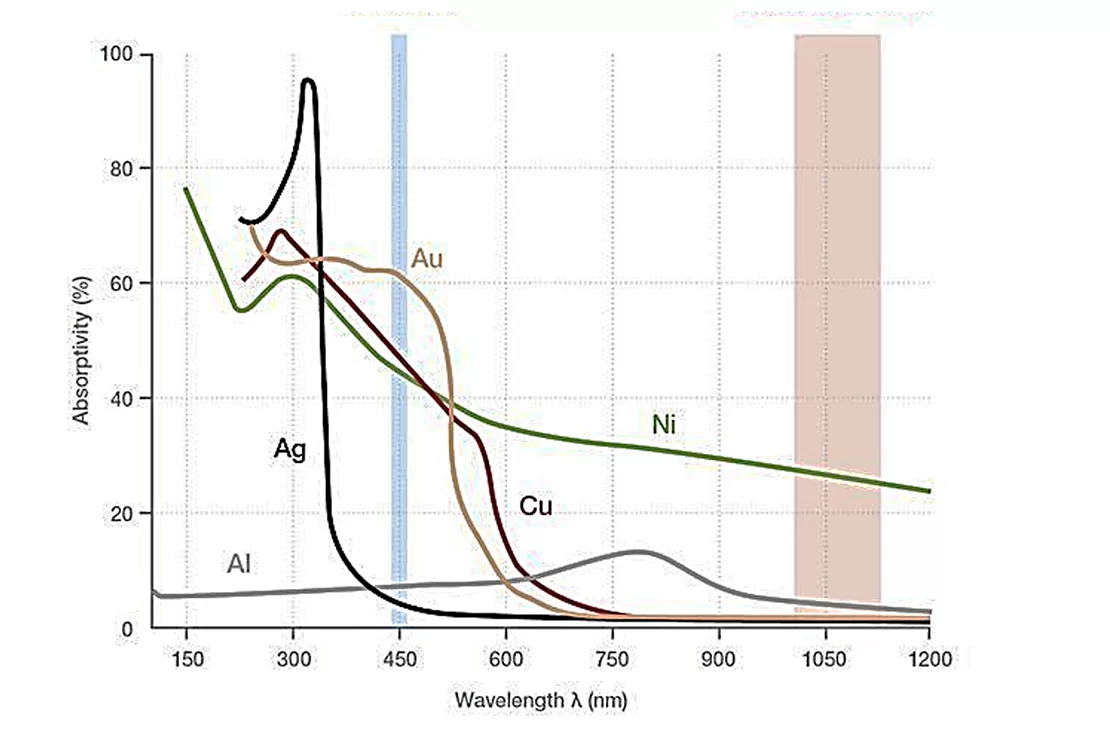

Blue laser absorption enhancement for solving non-ferrous solder ability problems

- Blue laser (455nm)has a significantly higher absorption rate for non-ferrous metals than conventional 1064nm NIR lasers(copper:X12,gold:X20);

- Dramatically increased laser energy utilisation;

- The high absorption of accumulated heat overcomes the energy dissipation of the material’s high thermal conductivity to achieve a molten pool;

- High absorption,low brightness+wide range of absorption coefficient consistency, ·stable soldering process.

| Absorption of blue laser by common metals comparison of multiplicity of absorption by near-infrared laser light | |||||

| Material | Aluminium | Copper | Gold | Tin | 304 SS |

| Multiple | 2.5 | 11.9 | 60.2 | 1.2 | 1.4 |

Industry Pain Points

- Welding of non-ferrous metals is a process bottleneck for batteries,motors and electronic packaging

- Copper and gold laser welding common technical problems

- Conventional welding(arc welding,plasma welding),brazing and other welding processes;low speed,abrasive,unstable,unable to be automated and intelligent

- Red laser,low absorption,high thermal conductivity of the material,changes in the absorption rate at different temperatures: the need for high laser power spattering,serious porosity;the process is not stable,high defective rate

- The low output power and high cost of the blue laser and the slow welding speed result in a large andwide molten pool,which causes the centre of the weld to collapse

| Technical Data | ||

| ltem | Parameters | Remarks |

| Laser power | Red laser waveband 3000w | Max.supported 15000W |

| Blue laser waveband 600W | Max.supported 3600W | |

| Beam quality | Red laser waveband≤1.8m? | @25um corediameterlaserfiber |

| Blue laser waveband focal spot size lmmX1mm | @FF=200mm | |

| Power Stability | ±2% | @24H |

| Optical platform Scanning range | Max:12mm | |

| Optical platform Scanning frecuency | Max:500Hz | |

| Max.welding capacity | Copper:6mm | Effective welding quality |

| Rated power | Max:8kW | |

CLOSE

Applications

Applications

The perfect combination: laser hybrid welding combines the advantages of laser welding with those of arc welding.In this welding process, an advancing laser beam initially heats the surface of the workpiece to vaporization point. This results in deep and narrow penetration. The subsequent arc forms a wide focal spot.

CLOSE

Key Points of STRONGEST LASER’s Service Philosophy

Key Points of STRONGEST LASER’s Service Philosophy

Customer First Philosophy

STRONGEST LASER prioritizes customers in its service approach.

High-Quality Products

The company bases its service on delivering high-quality products.

Efficient After-Sales Service

Provides fast, responsive, accurate, and localized after-sales service through its dedicated system.

Closed-Loop Management

Implements a comprehensive process from acceptance to completion to enhance management efficiency and customer satisfaction.

CLOSE

Certifications and Achievements

Certifications and Achievements

Since its establishment, STRION LASER has established itself in the domestic laser field with comprehensive capabilities such as technological innovation, product development, and market expansion, established a good brand image, and won unanimous praise from industry insiders.Has passed IS0 9001 quality system certification, IS0 3834 welding system certification, EU CE certification and other qualifications, and has applied for 95 intellectual property rights.

CLOSE

Become Our Distributor

Why become our distributor?

Benefit from our experts’ advice to meet your brand’s needs.

Product & Pricing Support

- High-performance laser welding equipment – including handheld, hybrid, and robotic systems

- Competitive distributor pricing – ensuring attractive profit margins.

- Customized product recommendations – tailored to different industry needs.

- Demo machine support – for marketing and customer demonstration

Marketing & Brand Empowerment

- Authorized use of our brand – legally use trademarks and branding materials.

- Exclusive territory protection – avoid price wars and protect your market.

- Exhibition and promotion support – marketing materials and event cost subsidies

- Joint promotion on our official website and social media – increase your local visibility

CLOSE

Frequently Asked Questions

Frequently Asked Questions

laser-hybrid-welding

What is Laser hybrid welding?

Laser hybrid welding combines the advantages of laser welding with those of arc welding. This welding process is becoming particularly established in shipbuilding, automotive production and rail vehicle construction.

Can Strongest Laser weld materials of different thicknesses and metals?

Sure, different types of metals (such as copper and stainless steel or aluminum) can be easily welded together.

What are the process advantages of laser hybrid welding?

Laser hybrid welding combines the advantages of both processes, allowing high weld depths and high gap bridging at the same time, and is particularly suitable for high thickness materials. The filler material can also have a positive effect on the properties of the weld.

Want customized solutions?

With our expertise and experience in welding, we are happy to advise you and work with you to find the perfect solution for your specific welding requirements. Please contact us.

CLOSE