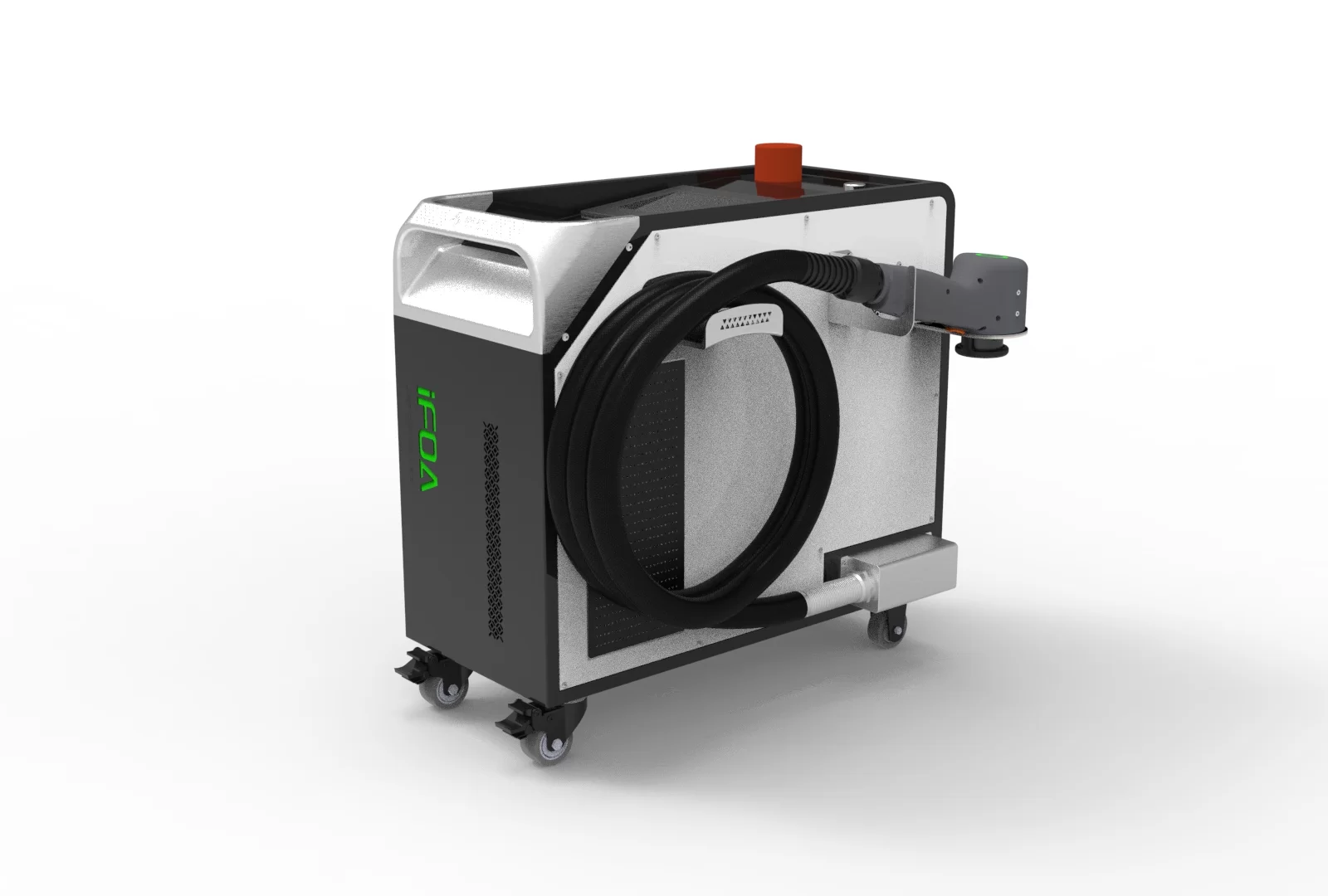

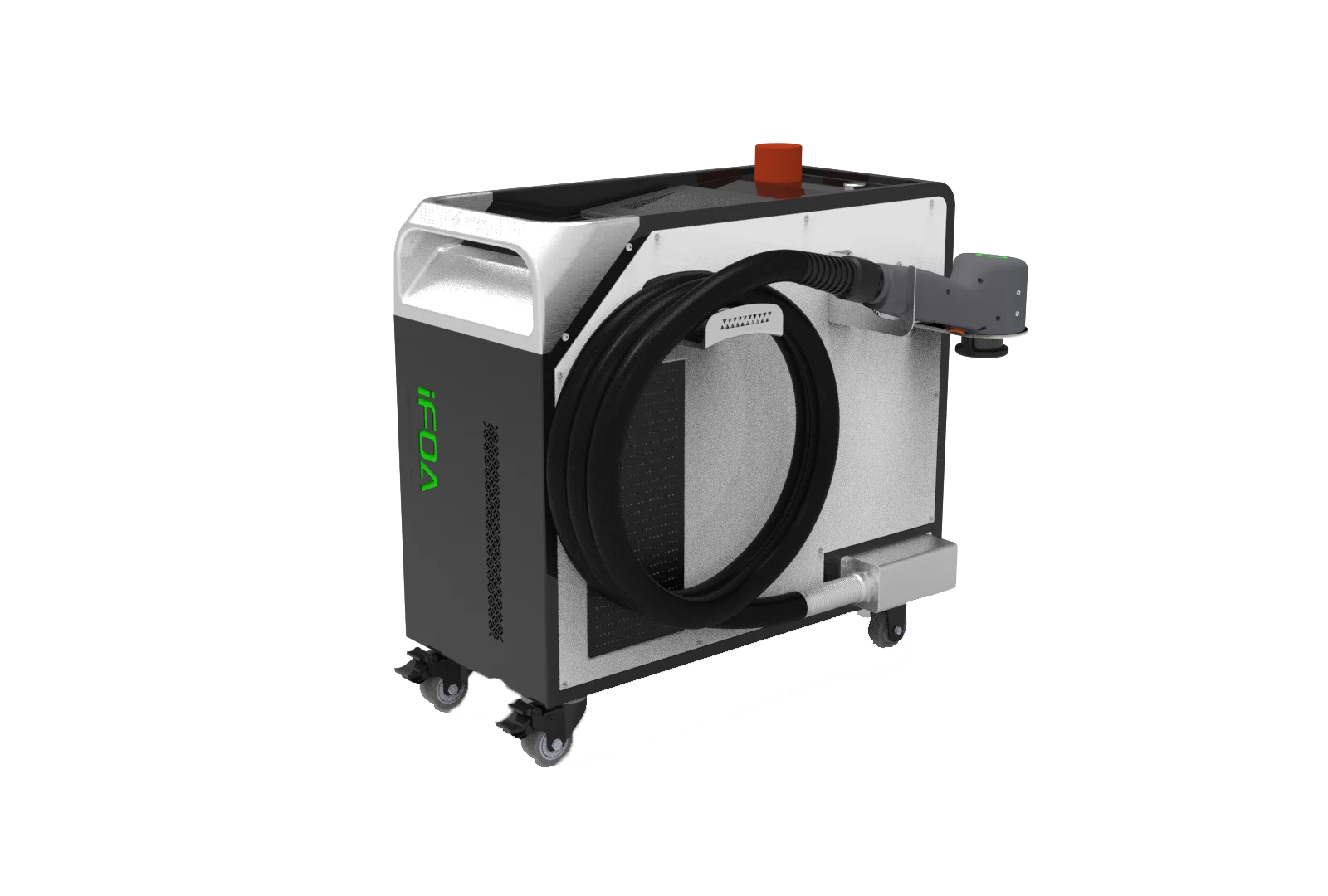

iFOA SERIES Laser cleaning machine

Where Light Reaches,a Smarter, Cleaner Future Begins

iFOA Series Laser Cleaning Machine

Clean Smarter, Clean Greener

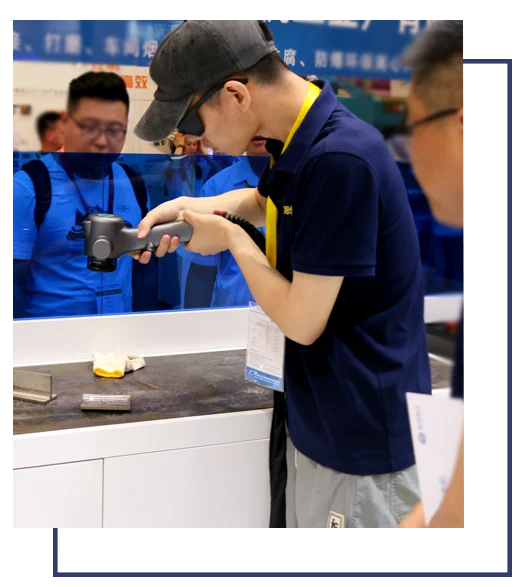

The STRION LASER iFOA Series features a user-friendly interface with dual modes for operators and engineers, reducing errors and shortening the learning curve. Designed for high adaptability, it supports integration with automation lines, robots, and lifting platforms for overhead applications. The system maximizes spatial flexibility while ensuring user safety — the laser only activates when the safety lock is pressed, preventing accidental firing and providing reliable protection in all working environments.

iFOA Series - Laser cleaning Machine

Where Light Reaches,a Smarter, Cleaner Future Begins

- LIGHTWEIGHT DESIGN-Weight: 30 kg, Torch: 0.9 kg

- INTEGRATED MAINFRAME STRUCTURE:Sealed Enclosure,Dust-Proof and High-Temperature Resistant. IP54 Protection for Safeand Reliable Operation

- SUPPORTS MULTIPLE CLEANING MODES

- SUPPORTS MULTI-LEVEL FUNCTIONAL EXPANSION

Product Parameters

| Model | iFOA-EU | ||||||

Energy Density(reference value for 254mm field lens) | 50J/cm² | 10J/cm² | 5J/cm² | 80J/cm² | 30J/cm² | 12J/cm² | 7J/cm² |

| Maximum Pulse Energy | 2mJ | 5mJ | 15mJ | 2mJ | 5mJ | 15mJ | 50mJ |

| Field lens focal length | F=254mm(Optional:F=160mm、F=330mm) | F=254mm(Optional:F=160mm、F=330mm) | |||||

| Focus spot (reference value for 254mm field lens) | 0.08mm | 0.25mm | 0.68mm | 0.05mm | 0.14mm | 0.43mm | 0.9mm |

| Scanning Speed | 10000mm/s | 10000mm/s | |||||

| Scanning width(reference value for 254mm field lens) | 140mm | 100mm | |||||

| Laser type | MOPA Pulsed fibre laser | MOPA Pulsed fibre laser | |||||

| Laser Wavelength | 1064nm | 1064nm | |||||

| Average power | ≥300W | ≥500W | |||||

Total power consumption | ≤1500W | ≤2000W | |||||

Operating environment temperature | 0~40°C | 0~40°C | |||||

Operating Humidity | 30%-50%RH | 30%-50%RH | |||||

Power Instability | <5% | <5% | |||||

Pulse Width | 13-500ns | 30-500ns | |||||

Power Adjustment Range | 0~100% | 0~100% | |||||

Pulse Frequency Range | 1-3000kHz | 1-4000kHz | |||||

Optical cable length | 5m (up to 30m) | 5m (up to 30m) | |||||

Laser Wavelength | 1064nm | 1064nm | |||||

Cooling System | Air-cooling | Air-cooling | |||||

Dimension | 580x385x556mm | 580x385x556mm | |||||

| Weight | ~35kg | ~36kg | |||||

Operating Mode | Handheld/Automated (Platform or Robotic Arm) | Handheld/Automated (Platform or Robotic Arm) | |||||

| Handheld torch Weight | ~960g(Air-cooling) | ~1.25kg(Air-cooling) | |||||

Product Core Benefits

Main Unit Advantages

- Compact and Agile:The main unit is lightweight and equipped with omnidirectional casters, making it easy to move and transport.

- Durable Integrated Frame:Designed with a one-piece frame structure, it can withstand heavy loads and vibrations, ensuring long-term durability.

- IP54 Protection:The machine body features IP54-rated protection, ensuring safe and reliable operation in various environments.

Handheld Torch Head Advantages

- Ergonomic Design: Designed for comfort with a supportive grip at the thumb crotch, making handheld operation easier and less fatiguing.

- Built-in Air Blowing System: Effectively removes dust while protecting the optical lens during operation.

- Dual Red Laser Alignment: External dual red beams enable fast and precise focusing, significantly improving efficiency.

- Integrated LED Lighting: Enhances visibility in low-light environments and allows real-time comparison of surface conditions before and after cleaning.

Key Problem-Solving Advantages

Precise and Controllable Cleaning

iFOA SERIES Laser cleaning enables standardized operations with high accuracy and consistency.

Labor Replacement for Higher Efficiency

Automates manual tasks, significantly boosting productivity and reducing labor costs.

Improved Quality and Lower Defect Rates

Enhances processing quality and reduces defects in downstream procedures, maximizing customer value.

Eco-Friendly and Clean Energy

A highly efficient, non-polluting cleaning solution that aligns with modern environmental standards.

Laser Cleaning VS. Conventional Techniques

Laser Cleaning vs. Chemical Processing

Laser cleaning is safer, cleaner, and eco-friendly. It avoids toxic chemicals, requires no consumables, and works on various surfaces. Chemical methods involve hazardous substances, complex preparation, and waste disposal. Laser technology reduces risks, simplifies operations, and supports sustainable manufacturing.

Laser cleaning is safer, more adaptable, and cost-efficient. Unlike dry ice blasting, it works on more surfaces and avoids constant material consumption. Dry ice may release CO₂ during cleaning, and poses risks like cold burns or gas buildup in confined areas, making laser a cleaner, safer long-term solution.

Sandblasting vs. Laser Cleaning

Laser cleaning delivers greater precision without the health hazards of sandblasting. Sandblasting releases fine dust that can cause severe lung diseases like silicosis, despite safety measures. It also produces hazardous waste, adding to environmental concerns. Laser technology eliminates airborne particles and waste, offering a cleaner, safer alternative.

APPLICATIONS

Laser technology is increasingly being adopted across a wide range of industries as an innovative solution for surface treatment and cleaning. It provides a non-contact, highly accurate, and eco-conscious alternative to traditional abrasive methods.

Its applications span across:

Industrial Processing

Electronics Industry

Medical Device Maintenance

Manufacturing Lines

Automotive Sector

Cultural Relics & Artwork Restoration

Aerospace Engineering

Marine and Shipbuilding

FREQUENTLY ASKED QUESTIONS

laser-cleaning-machine

What Is Laser Cleaning?

Laser cleaning is a non-contact, precise method to remove rust, dust, dirt, and oxidation from various surfaces. It uses concentrated light energy to eliminate contaminants without harming the base material. Unlike traditional methods, it produces no chemical waste, making it eco-friendly. This technique can clean complex shapes and targeted areas with high accuracy, leaving surrounding surfaces untouched. It is a safe, clean, and efficient solution widely used for surface preparation across multiple industries.

How Laser Cleaning Works?

Laser cleaning uses fiber laser ablation to remove rust, paint, oil, and other surface contaminants. Infrared light is generated in an optical fiber and transmitted to the scanhead via a fiber cable. Inside the scanhead, single or dual beam technology shapes the laser pattern. The focused beam vaporizes unwanted material without damaging the base surface. This non-contact, eco-friendly method is widely used in industries like automotive and aerospace. Compared to traditional cleaning, it offers higher precision, minimal waste, and no need for chemicals or abrasives.

What Contaminants Can Laser Cleaning Effectively Remove?

Laser cleaning effectively removes a wide variety of surface impurities, including rust, grease, paint layers, oxides, powder coat, epoxy, rubber residues, carbon buildup, radioactive dust, electrolytic materials, anti-corrosion films, and other unwanted coatings. It’s a precise and efficient solution for industrial surface preparation.

Is Laser Cleaning Effective for Removing Heavy Rust or Thick Paint?

Yes, laser cleaning can handle heavy rust or thick paint layers. For tougher buildup, combining a high-power continuous laser with a low-power pulsed laser enhances removal efficiency. This approach ensures deeper penetration while maintaining surface integrity, making it suitable for demanding industrial cleaning tasks.

Does Laser Cleaning Damage the Base Material?

When correctly applied, laser cleaning preserves the integrity of the underlying material. For delicate surfaces like thin metals or heat-sensitive components, using a finishing-grade laser system ensures safe, precise cleaning without causing harm.

Is Laser Cleaning Safe for Users and Eco-Friendly?

Laser cleaning is a green process that eliminates the need for chemicals and abrasive materials. Operators must always use suitable laser safety glasses when working with lasers above Class I. With these safety measures, laser cleaning offers an effective and environmentally responsible method.