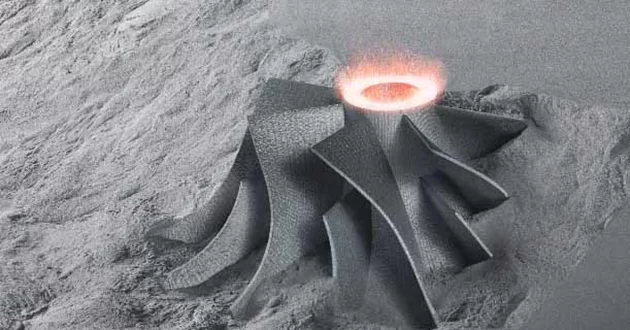

Fiber Lasers for Additive Manufacturing

high efficiency,High-quality and high-precision printing

Additive Manufacturing Series Fiber Lasers/Special laser

narrow linewidth high quality laser beam fiber lasers/ high-power fiber laser source

STRION LASER continuously introduces outstanding talents for cultivation, and has established a high-level professional R&D team to independently develop additive manufacturing dedicated fiber lasers, narrow linewidth high quality laser beam fiber lasers, and high-power fiber laser source; Widely used in aerospace, medical equipment, automotive and other fields.

STR-AM Series - UNIQUE TO US BETTER THAN ALL

- More than 200% savings for multi-light devices, special for multi-light printing devices

- Up to 52% efficiency of electro-optical conversion of the whole machine

- The control interface and logic show stronger compatibility, making them convenient for various application extensions

- Collimation Spot Accuracy<0.1mm / Beam Quality<1.1 / Power output control and monitoring accuracy 1W

Special laser - Narrow linewidth high quality laser beam /high-power laser beam

- Compact, Lightweight, and Modular Design Concept

- Excellent Beam Quality

- Self-Development and Production

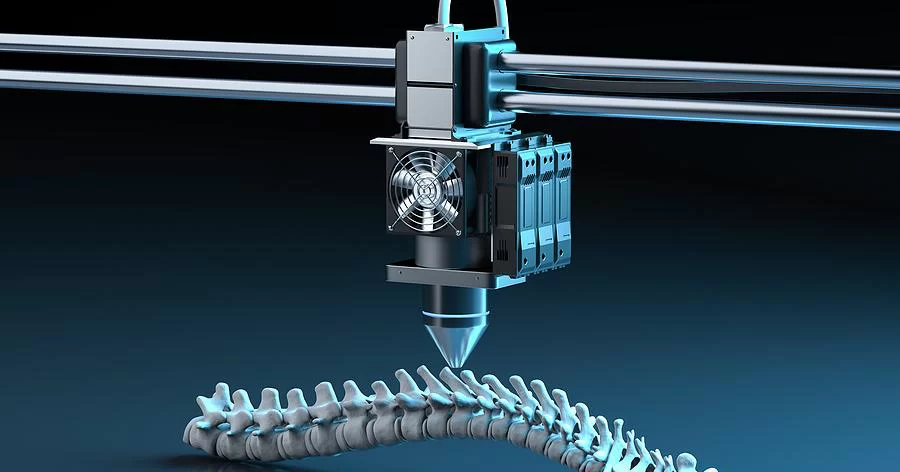

Fiber Lasers for Additive Manufacturing

Fiber Lasers for Additive Manufacturing

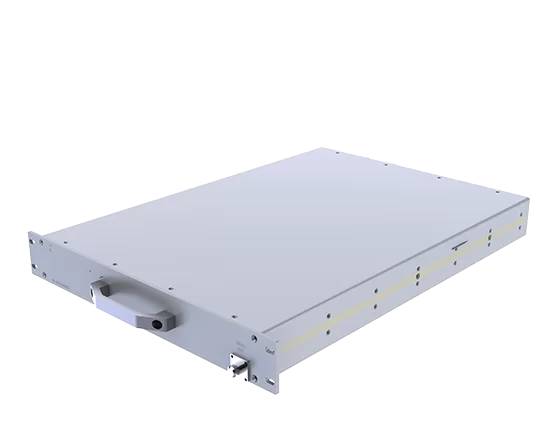

The STR-AM series fiber laser from Sichuang Laser, designed for 3D metal additive applications, has higher power stability, lower power attenuation, higher beam quality and brightness, and is widely used in industries such as aerospace, medical equipment, and automotive. The hardware and software interfaces of this series of lasers have strong compatibility, making them suitable for parallel substitution of similar products and functional expansion of platform equipment.

| Model | STR-AM-R-series | STR-AM-M-series | ||||

| R350 | R500 | R750 | R1000 | M350 | M500 | |

Rated output power | 350W | 500W | 750W | 1000W | 350W | 500W |

Central wavelength range | 1080±2nm | |||||

Mode ofoperation | CW/Modulated | |||||

Max. modulationfrequency | 20kHz | |||||

Continuous power instability | ±1% | |||||

Indicated laser power | 0.3-1mW | |||||

Beam quality | <1.1 | |||||

Polarization state | Random | |||||

Output method | QCS/QBH | |||||

QCS Output spot diameter | 5/7.5mm | |||||

Output fiber core diameter | 10μm | |||||

Output fiber length | 5/10/15m(Customizable) | |||||

Control mode | RS232/Ethernet/ANALOG interface | |||||

Electro-optical efficiency | ≥35% | |||||

Output power regulation range | 5%~100% | |||||

Emission-on response time | 25μs | |||||

| Emission-off response time | 20μs | |||||

Operating temperatur | 10~40℃ | |||||

| Humidity | 10~70%RH | |||||

Storag | -20℃~60℃ | |||||

| Cooling method | Water-cooling | |||||

| Minimumflowrequirements | 4L/min | 4L/min | 8L/min | 8L/min | 3L/min | 3L/min |

Input power | 220V AC | 70V DC | ||||

Dimension | 571.5×482.6×132mm | 407×332×53mm | ||||

Weight | 22kg | 25kg | 28kg | 30kg | 11kg | 12kg |

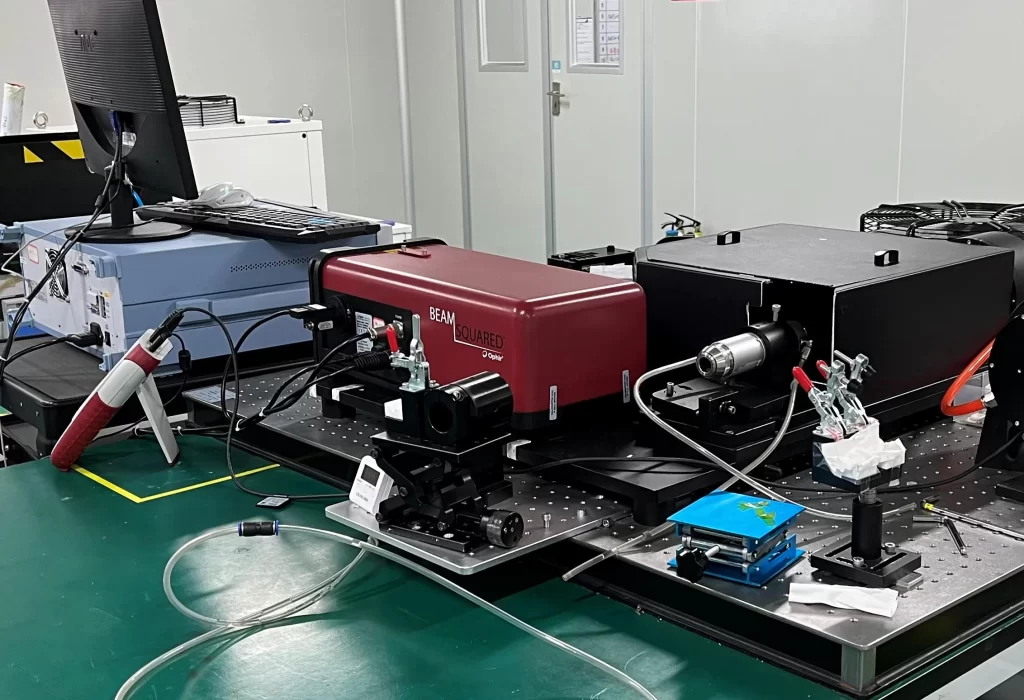

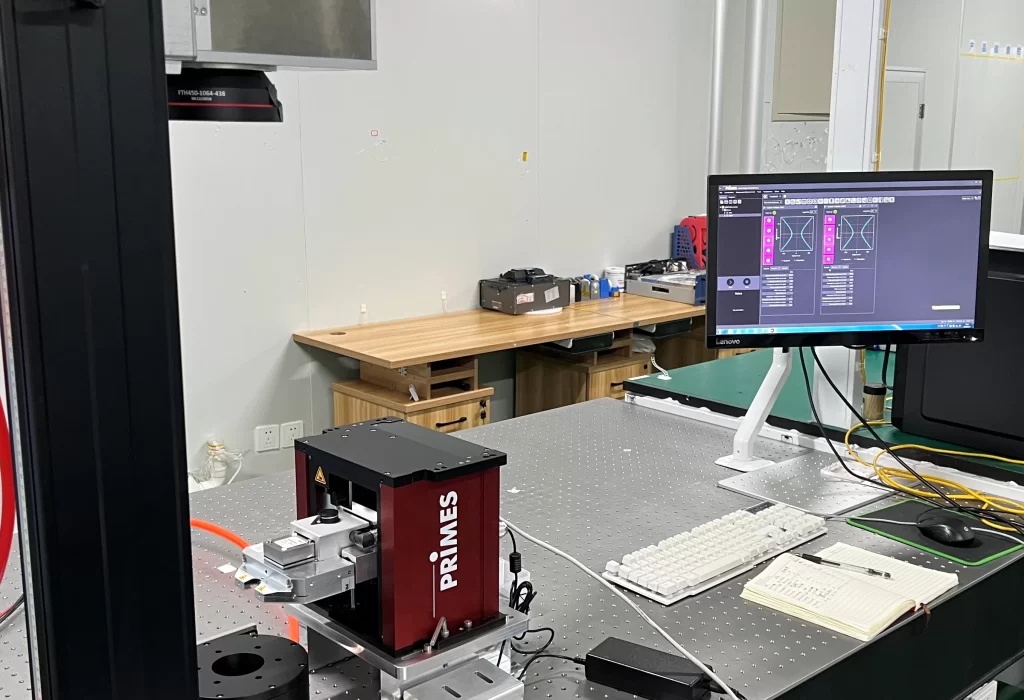

50+COMPREHENSIVE RELIABILITY TESTING

We meticulously craft every detail to provide users with unparalleled quality assurance and long-term trust. Choosing STRION LASER is choosing a partner who can withstand the test of time.

MORE COMPREHENSIVE RELIABILITY TEST | |

| Integrated device -40 ℃~85 ℃ 100 cycles cold and hot shock cycle test | Laser 85 ℃/85% RH 500h storage test |

| Integrated device -40 ℃ 500h storage test | Laser 2000HZ/20G acceleration vibration test |

| Integrated Device 20G/500HZ Sinusoidal/Random Vibration Test | Laser 12 edges, 8 corners, 6 faces, 30 repeated drop tests |

| Output device 85 ℃/85% RH 500h high temperature and high humidity storage test | Laser 40000 times repeated light on test |

| Output device -40 ℃~85 ℃ 100 cycles cold and hot shock cycle test | Laser spot calibration test |

| Output device -40 ℃ 500h storage test | Laser beam focus test |

| Output device 20G/500HZ sine/random vibration test | Laser beam quality testing |

| Output device armored cable expansion test | Laser output analog response speed test |

| Reliability testing of gain fiber optic high-temperature boiling water | Laser modulation response speed test |

| Fiber optic flaw detection test | Laser external power input response speed test |

| Wire harness anti-interference test | Linear testing of laser power |

| Long term reliability testing of wiring harness | Real time monitoring and testing of lasers |

| Serial communication test | 8-hour power stability test of laser |

| Network communication testing | Laser power compensation calibration test |

| Laser interface contact 4kV/isolated 8kV test | 120h factory aging test for laser |

| 2kV surge test for laser interface | Laser indication light calibration test |

| 2kV pulse group impulse test for laser interface | Passed CE certification |

| 50A high current load test for drive system | Certified by FCC |

| Ripple testing of key signals in control systems | Certified by IC |

| Structural strength testing of key support components for lasers | Certified by PSE |

| Laser structural components GB/T 10125 48 hour salt spray test | Certified by IEC |

| Anti freeze corrosion test of laser cooling system | FDA certified |

| Laser heat dissipation channel 1MPa pressure test | |

CLOSE

Narrow Linewidth high quality fiber laser beam

2KW Narrow Linewidth high quality laser beam

Based on its independently developed passive components, STRION LASER has achieved innovative breakthroughs in pumping technology. The 2kW narrow linewidth single mode fiber laser is its a mass-produced model utilizing the innovative 976nm pumping technology and adopting modular design. Featuring compact structure, good reliability and environmental adaptability, this model meets the requirements for ultra-high power beam combination and finds wide applications in industrial, medical, aerospace, and military fields.

| Optical Characteristics | Unit | Symbol | Test Condition | Min | Typical Value | Max | Remarks |

| Operating mode | Continuous | ||||||

| Output power | KW | P | I=100% | 2 | 2.1 | Scalable to 2.5 kW | |

| Center wavelength | nm | λ | 1030 | 1080 | Any value within this range | ||

| Spectral width | nm | 20dB RMS | 0.25 | 0.35 | |||

| Output power instability | % | 2 | |||||

| Output method | QBH/Fiber | ||||||

| Beam quality | M² | 1.4 | 1.5 | 1.6 | |||

| Size | mm | 620*482*66 | |||||

| Weight | Kg | 24 | |||||

| Power input | VDC | ||||||

| Input power consumption | kW | 8 | |||||

| Operating humidity range | % | 10 | 85 | ||||

| Operating temperature range | ℃ | -20 | 60 | Customizable | |||

| Storage temperature range | ℃ | -40 | 70 | Customizable | |||

CLOSE

High Power high quality laser beam

8-10kW High Power high quality laser beam

The 8-10kW single-mode fiber laser of STRION LASER is based on its independently developed pump combining technology and adopts the single-stage MOPA structure, which make it possess excellent beam quality under high power output, featuring high brightness, small quantum loss, good environmental adaptability, high working reliability, compact structure and small size, and have bright application prospects in the industrial and military security fields.

8kw high quality fiber laser beam

OpticalCharacteristics | Unit | Symbol | Test Condition | Min | Typical Value | Max | Remarks |

Operating mode | Continuous | ||||||

Output power | kW | P | I=100% | 8 | |||

Center wavelength | nm | λ | 1070 | ||||

Spectral width | nm | Δλ | 3dB | 5 | |||

Output power instability | % | 5 | |||||

Red light power | mW | 0.3 | 1.0 | ||||

Output method | QBH | ||||||

Beam quality | M² | 2 | |||||

Size(Excluding water distribution pipeline) | mm | 600*500*682.5 | |||||

Weight | Kg | 165 | |||||

Working voltage | VDC | 190-300VDC | |||||

Input power consumption | kW | 28 | |||||

Operating humidity range | % | 10 | 85 | ||||

Operating temperature range | ℃ | -20 | 60 | Customizable | |||

Storage temperature range | ℃ | -40 | 70 | Customizable | |||

10kw high quality fiber laser beam

OpticalCharacteristics | Unit | Symbol | Test Condition | Min | Typical Value | Max | Remarks |

Operating mode | Continuous | ||||||

Output power | kW | P | I=100% | 8 | |||

Center wavelength | nm | λ | 1070 | ||||

Spectral width | nm | Δλ | 3dB | 5 | |||

Output power instability | % | 5 | |||||

Red light power | mW | 0.3 | 1.0 | ||||

Output method | QBH | ||||||

Beam quality | M² | 2 | |||||

Size(Excluding water distribution pipeline) | mm | 600*500*682.5 | |||||

Weight | Kg | 165 | |||||

Working voltage | VDC | 190-300VDC | |||||

Input power consumption | kW | 28 | |||||

Operating humidity range | % | 10 | 85 | ||||

Operating temperature range | ℃ | -20 | 60 | Customizable | |||

Storage temperature range | ℃ | -40 | 70 | Customizable | |||

CLOSE

Applications

Applications

The hardware and software interfaces of this series of lasers provide strong compatibility, and can be used as the functionally-identical alternative items for similar products and functional expansion of relevant platforms.

CLOSE

Frequently Asked Questions

Frequently Asked Questions

fiber-lasers-for-additive-manufacturing

What are the current applications of AM lasers in?

AM laser is a specialized laser launched by our company for the 3D printing industry, which can currently be applied in fields such as aerospace, automotive manufacturing, molds, industrial design, medical biology, etc.

What are the advantages of STRONGEST LASER?

1. High power stability and perfect precision control: printing power stability of ± 1%, improving printing accuracy; Laser power 5% -100% proportional linear output debugging.

2. High electro-optical conversion rate up to 52%.

3. Strong control compatibility: The laser control interface has strong logical compatibility, making it convenient for various applications to expand.

4. Strong environmental adaptability and high reliability: It has passed various national standard tests (such as high temperature and low temperature, transportation vibration, dripping, salt spray, etc.)

How many people are currently in the R&D team of STRONGEST LASER?

Our entire company’s R&D team has over 80 people (you can research and write this number based on the actual number of R&D personnel in the company), with a dedicated R&D team for additive products of over 30 people, including technical personnel from various research institutes and universities under the 985.211 project. Additive laser products are independently developed by combining multiple technical talents and engineers.

CLOSE