Automated welding systems

Redefine the Performance of Laser Welding

STRION LASER-Automated welding systems

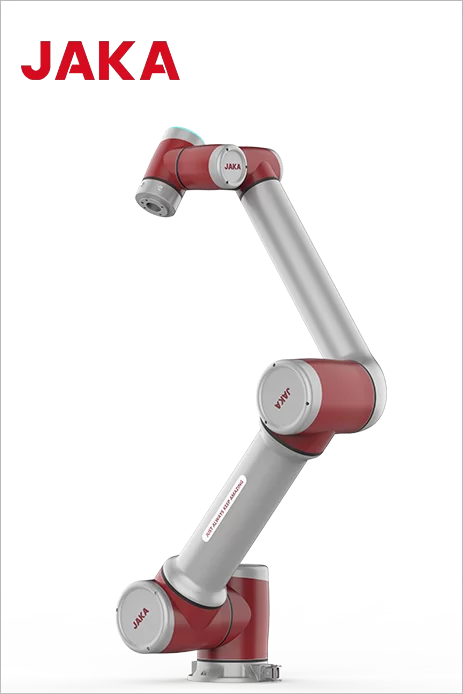

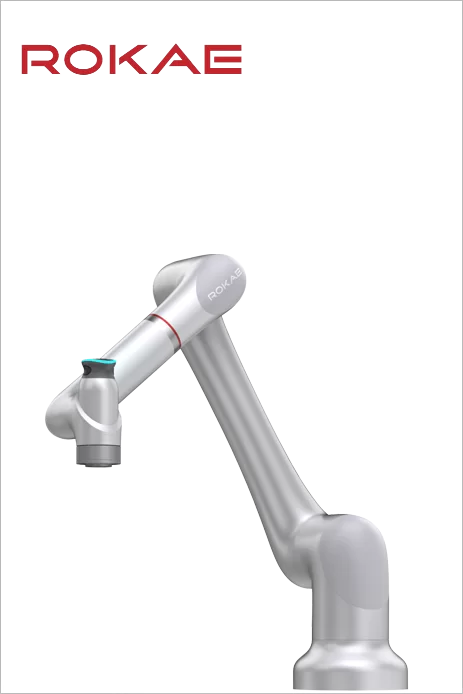

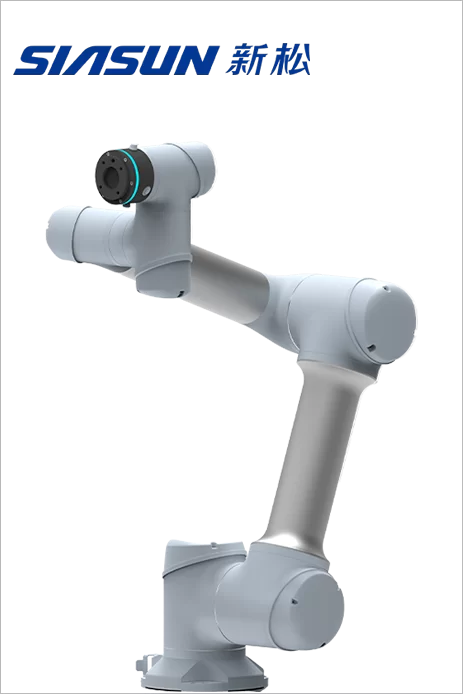

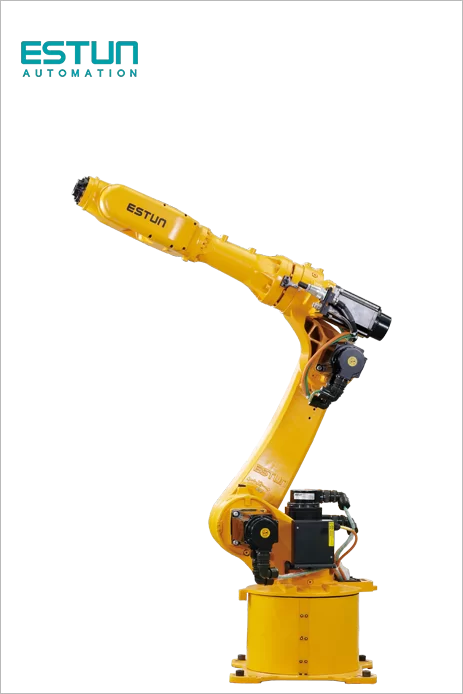

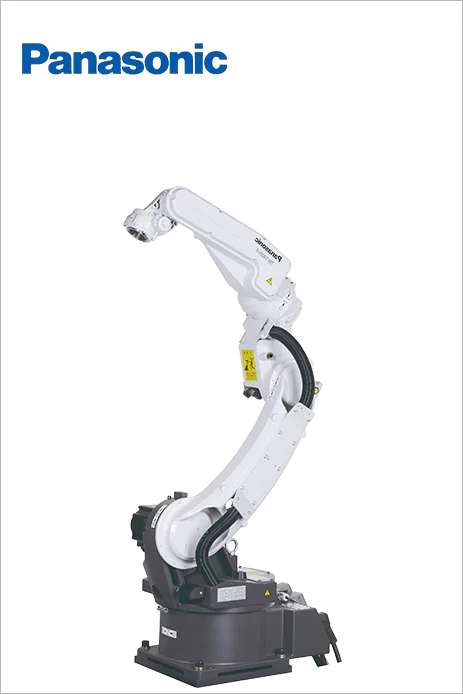

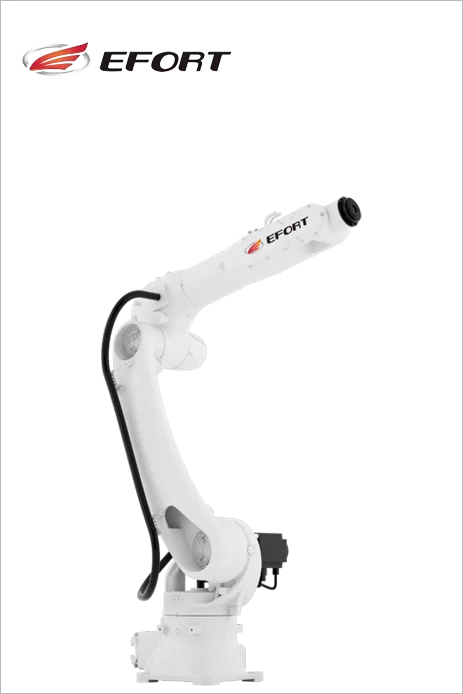

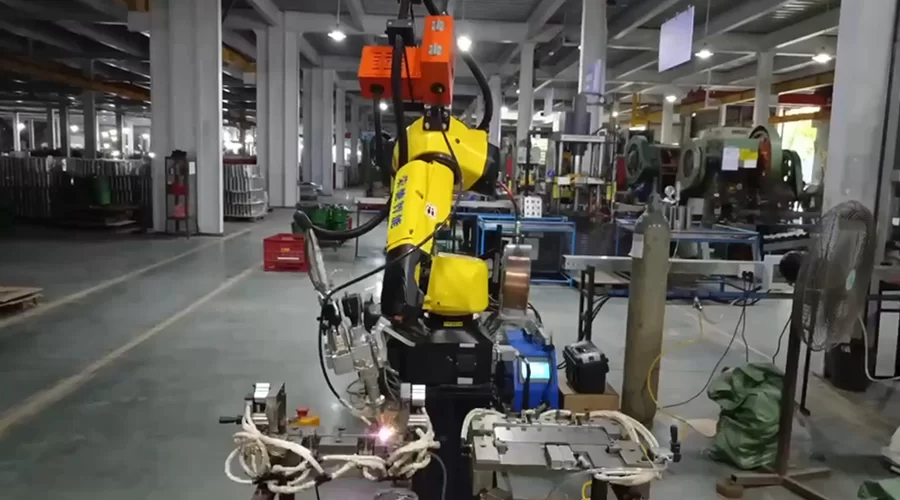

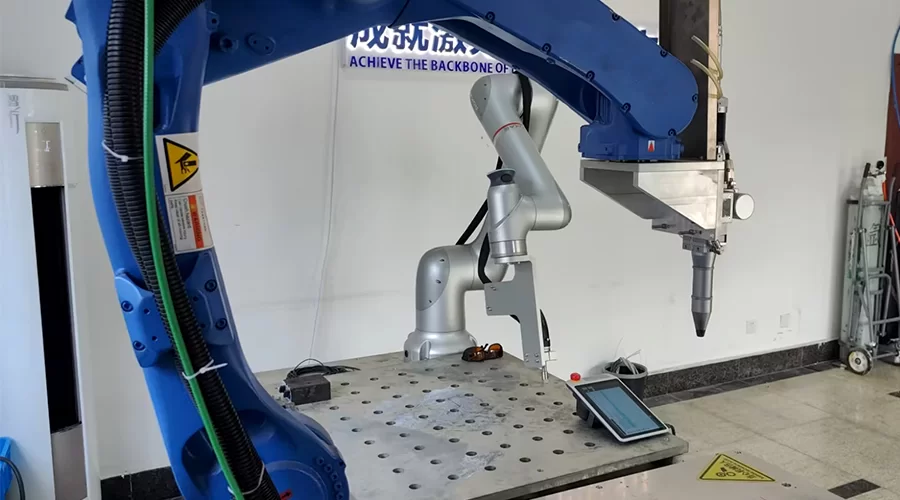

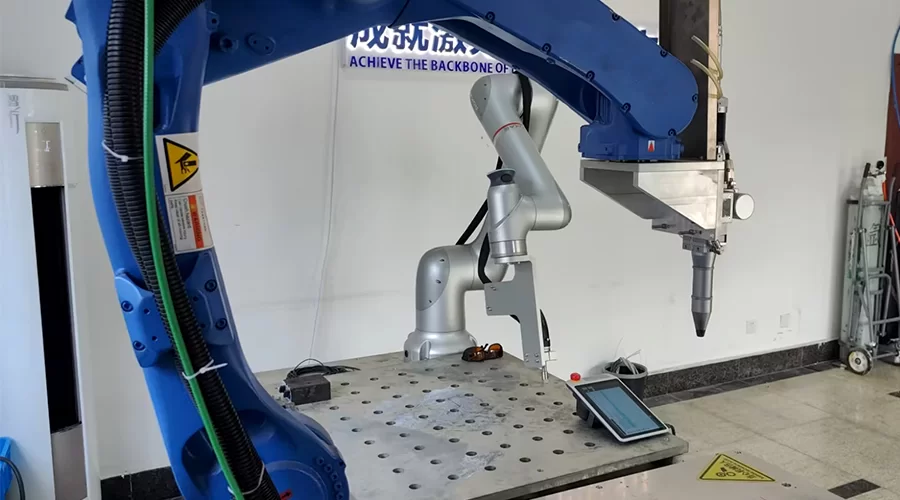

Cobot & Industrial robots

The STR-AW series is compatible with collaborative robots and industrial robots from various brands, ensuring consistency and stability in welding, as well as unlimited process expansion, achieving a surge in work efficiency.

STR-AW Series - SAFETY AND FLEXIBILITY WELDING AS YOU LIKE

- High Security And Flexibility Easy To Operate

- One-stop Adaptation With Less Problems

- Digital Communication For Microsecond Laser-robot Communication

- Deep Co-development To Create Laser Welding Process Database

STR-AW Series - PRECISE INTELLIGENT CONTROL EMPOWERS WELDING

- One-stop Solution, Easy Operation

- Professional Process Database To Realize Intelligent Production

- Unique design of welding torch,easy to operate and less malfunctioning

- Completed Afte-sales Service

STR-AW Parameters

STR-AW Parameters

Items |

STR-AW350 |

STR-AW450 |

STR-AW550 |

STR-AW850 | |

Rated input power supply | Single phase220V | Single phase220V | Single phase220V | Three phase380V | |

Input power frequency | 50/60Hz | 50/60Hz | 50/60Hz | 50/60Hz | |

Laser power | 900W | 1200W | 1500W | 3000W | |

Rated input power | 3800W | 4200W | 5400W | 10500W | |

Working temperature | -20℃~60℃ | -20℃~60℃ | -20℃~60℃ | -30℃~60℃ | |

Working humidity | 0-90% | 0-90% | 0-90% | 0-90% | |

Product dimensions | 675mm×310mm×580mm | 673mm×310mm×605mm | 673mm×310mm×605mm | 863mm×410mm×724mm | |

Product weight | 39kg | 43kg | 45kg | 70kg | |

Armored cable length | 10m(Customizable) | 10m(Customizable) | 10m(Customizable) | 10m(Customizable) | |

Pre set process package | 24 | 30 | 40 | 50 | |

Control interface | I/O;D/A | ||||

Cooling mode | Dual-circuit refrigerant direct cooling | ||||

Welding mode | Spot welding/Continuous spot welding/ Pulse welding/Continuous welding | ||||

CLOSE

Cobot Standard Machines

Cobot Standard Machines

The STRION LASER Cobot can help alleviate the challenges of the welder shortage by providing a collaborative robot solution that can be easily operated by welders of varying skill levels, ensuring that welding production demands can be met efficiently and effectively.Let this collaborative welding robot handle repetitive and mundane welding tasks while your welders capitalize on their hard-earned welding skills.

CLOSE

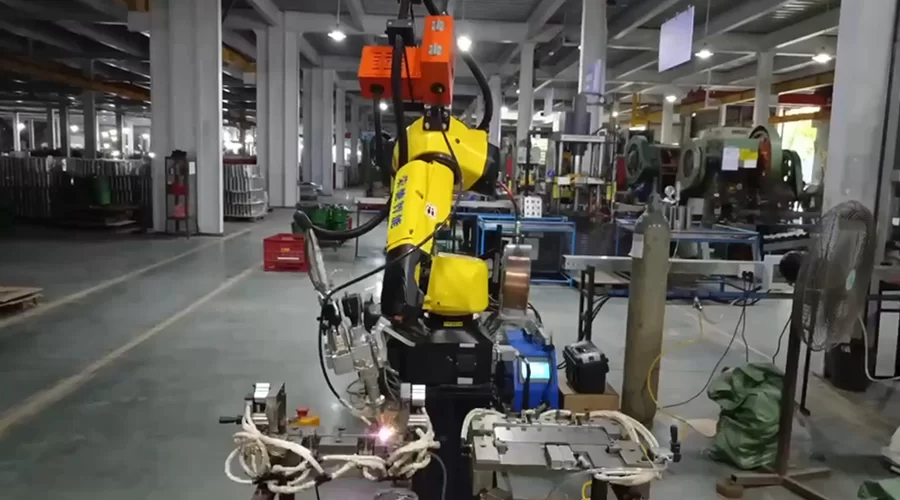

Industrial Robot Laser Welding Station

Applications

Applications

Different from assembling welding processes from different manufacturers, STRION LASER integrates welding processes and is a manufacturer that integrates automatic welding. Ensure seamless and stable welding and infinite extension of the process, achieving a significant increase in work efficiency.

CLOSE

Key Points of STRONGEST LASER’s Service Philosophy

Key Points of STRONGEST LASER’s Service Philosophy

Customer First Philosophy

STRONGEST LASER prioritizes customers in its service approach.

High-Quality Products

The company bases its service on delivering high-quality products.

Efficient After-Sales Service

Provides fast, responsive, accurate, and localized after-sales service through its dedicated system.

Closed-Loop Management

Implements a comprehensive process from acceptance to completion to enhance management efficiency and customer satisfaction.

CLOSE

Certifications and Achievements

Certifications and Achievements

Since its establishment, STRION LASER has established itself in the domestic laser field with comprehensive capabilities such as technological innovation, product development, and market expansion, established a good brand image, and won unanimous praise from industry insiders.Has passed IS0 9001 quality system certification, IS0 3834 welding system certification, EU CE certification and other qualifications, and has applied for 95 intellectual property rights.

CLOSE

Become Our Distributor

Why become our distributor?

Benefit from our experts’ advice to meet your brand’s needs.

Product & Pricing Support

- High-performance laser welding equipment – including handheld, hybrid, and robotic systems

- Competitive distributor pricing – ensuring attractive profit margins.

- Customized product recommendations – tailored to different industry needs.

- Demo machine support – for marketing and customer demonstration

Marketing & Brand Empowerment

- Authorized use of our brand – legally use trademarks and branding materials.

- Exclusive territory protection – avoid price wars and protect your market.

- Exhibition and promotion support – marketing materials and event cost subsidies

- Joint promotion on our official website and social media – increase your local visibility

CLOSE

Frequently Asked Questions

Frequently Asked Questions

automated-welding-systems

Why should I buy a robot instead of a welder?

The STRONGEST LASER collaborative robot is mainly designed to help welders improve their work efficiency. Although capable of completing various welding and cutting tasks, it is particularly suitable for handling repetitive welding work. Reduced the time spent by welders on rework and grinding.

Why use laser welding robots instead of arc welding robots?

Laser welding is one of the many welding methods and cannot replace traditional welding methods in all welding applications. However, laser welding has many advantages over MIG and TIG welding:

1. Welding speed increased by 6-10 times

2. Reduce heat affected zone

3. Higher welding accuracy

4. Less post weld processing is required

5. Under the same welding application conditions, energy savings of over 50% are achieved

6. General workers can also operate it, saving labor costs

Is laser welding safe?

Laser welding is safe, and like other welding methods, laser welding also requires some safety measures.

Safety is the top priority for all STR-HW series, with eight safety measures to safeguard welders.

1. Welding LOOP safety protection: The equipment is equipped with safety clamps to avoid accidental light emission after lifting the gun;

2. Light output warning protection: The welding gun and equipment have clear light output prompts to clearly indicate the warning;

3. Pressure protection: The equipment is equipped with pressure protection, and light is allowed to be emitted when the external gas connection is normal;

4. Welding gun temperature protection: The welding gun design effectively avoids heating and prevents personal injury caused by high temperatures;

5. Protection against accidental touch of welding gun button: The design of the welding gun button protection shell prevents the welding gun from accidentally emitting light due to placement errors;

6. Protective mirror protection: equipped with protective mirror installation detection function, allowing light to be emitted when the protective mirror installation is completed;

7. External Chain Protection: Equipped with an external safety chain interface, it can be connected to external emergency stops, safety pedals, and other devices to facilitate safety control in factories and assembly lines;

8. Emergency switch: A convenient button is installed on the top of the equipment to immediately stop the device in case of an accident.

Do I need experience using a laser welding machine?

Not at all. Regardless of your welding experience, whether it is laser or other methods, the STR-HW series laser welding machine welding technology is easy to learn and comes pre installed with multiple welding process packages suitable for the most common materials and thicknesses. You can also create your own custom welding process package to match your welding speed and required welding depth.

Are collaborative robots used to replace welders?

No, the fact is quite the opposite. Collaborative robots work together with welders to assist in completing various tasks and tasks. The STRONGEST LASER collaborative robot system requires skilled welders to perform various welding tasks. Collaborative robots, like other tools, are designed to help users produce higher quality products faster and more efficiently.

CLOSE