Aluminum alloy welding presents unique challenges due to the material’s high thermal conductivity and tendency to form oxide layers. To achieve high-quality welds, it is crucial to follow specific guidelines for preparation, testing, and technical considerations. This article provides key steps and considerations to ensure a successful aluminum alloy welding process, whether for manual, semi-automatic, or fully automated applications.

On-Site Trial Guidelines

To ensure accurate and efficient aluminum alloy welding demonstrations, please prepare the following information in advance:

Material Details:

- Type and thickness of the material

- Dimensions and shape of the workpiece

- Joint configuration and welding position

Welding Requirements:

- Expectations for weld appearance and internal quality

- Specific standards for bead width and welding strength

Automation Compatibility (if applicable):

- Details about the customer’s automation system and control method

- Mounting position of the welding head on existing equipment

- Interference checks for robotic motion paths

- Verification that the laser focus can accurately reach the intended weld seam

Key Technical Considerations for Aluminum Welding

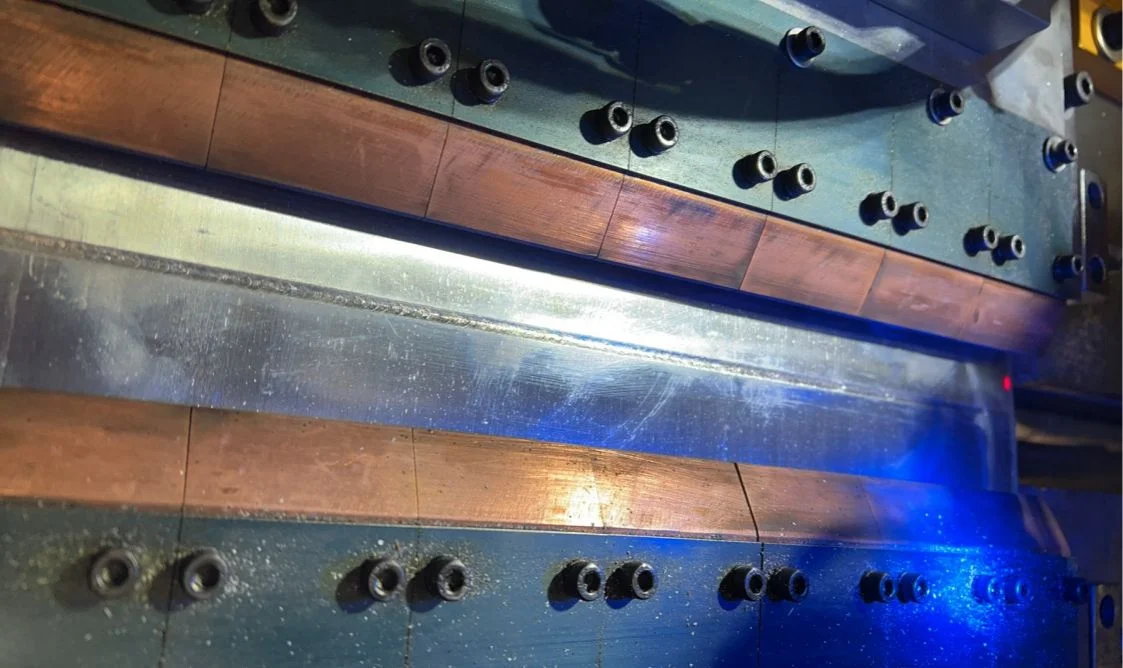

Welding Head Angle

Slightly tilt the welding head to minimize laser back-reflection and protect optical components from damage.

Laser Focus Position

Ensure accurate focus alignment to avoid reflective burnback, which may damage the lens or copper nozzle.

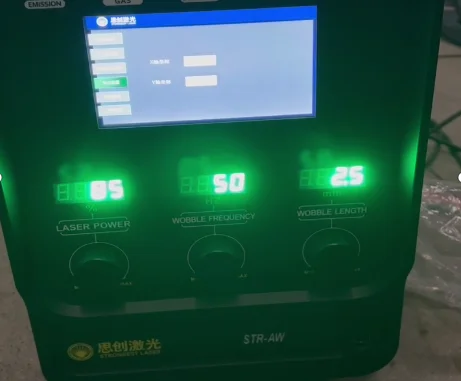

Power and Travel Speed

Aluminum requires relatively higher welding speeds and moderate power levels. Excessive power or slow speed can lead to weld collapse or excessive penetration.

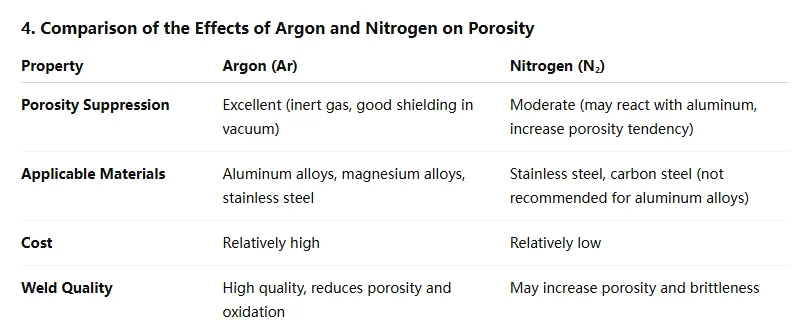

Shielding Gas Selection

Choose the proper shielding gas (e.g., argon or argon-helium mix) to stabilize the arc and protect the molten pool from oxidation.

Conclusion

To achieve the best results in aluminum alloy welding, it’s important to follow the outlined guidelines, prepare the workpieces adequately, and account for key technical considerations. STRION LASER provides comprehensive technical support and precision solutions tailored for aluminum alloy applications, including manual, semi-automatic, and fully automated welding systems.

Contact us to schedule a live demo or technical consultation. Our experts are here to ensure your welding projects run smoothly and effectively.