News

The Top Laser Intelligent Manufacturing Expert

First-class R&D team, driving the industry’s technological innovation, the enterprise competitiveness continues to increase

News

The training was structured into two levels—Level 1: Foundation Training and Level 2: Advanced Training—covering everything from basic installation to advanced fiber maintenance and welding process optimization.

The combination of aluminum and laser welding seems like a perfect match at first glance. However, due to their conflicting characteristics, this pairing presents numerous challenges in practical welding operations.

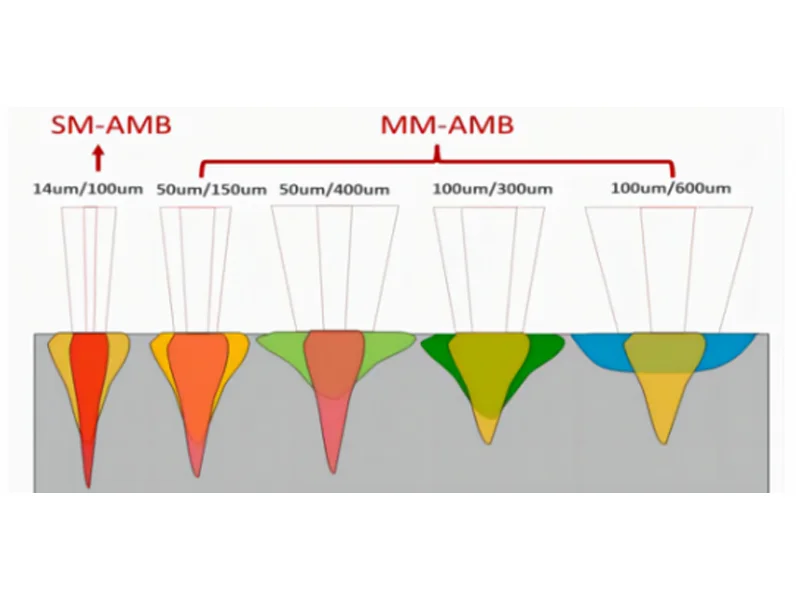

This article provides a detailed comparison of small-core and large-core fiber lasers, highlighting their respective strengths and ideal use cases.

STRION LASER Drives Innovation in High-Power Continuous Fiber Lasers at the OVC EXPO

BIO-YD has applied STRION LASER’s STR-HW Series handheld laser welding machine to the fabrication of high-standard sanitary-grade containers.

Some operators want to remove the interlock, but such welding operation is a very dangerous behavior - especially when using handheld laser welding machines or fiber laser welding systems.

STRION LASER is pleased to unveil its upgraded brand logo, representing a refined visual identity that bridges ancient philosophy with modern technology — a natural evolution aligned with the company's growth in the laser welding industry.

As a leading enterprise in China’s high-power laser technology sector, STRION LASER (SSichuan Strongest Laser Technology Co.,Ltd.) was invited to attend the event.

Thermal effects dominate the cleaning mechanism. High power and large processing area adaptability. Balance between low cost and high efficiency

This article explores the key benefits of handheld laser welding machines and their growing significance in the fabrication industry.