News

The Top Laser Intelligent Manufacturing Expert

First-class R&D team, driving the industry’s technological innovation, the enterprise competitiveness continues to increase

News

This article explores compatible materials, cleaning applications, and real-world use cases for laser cleaning systems.

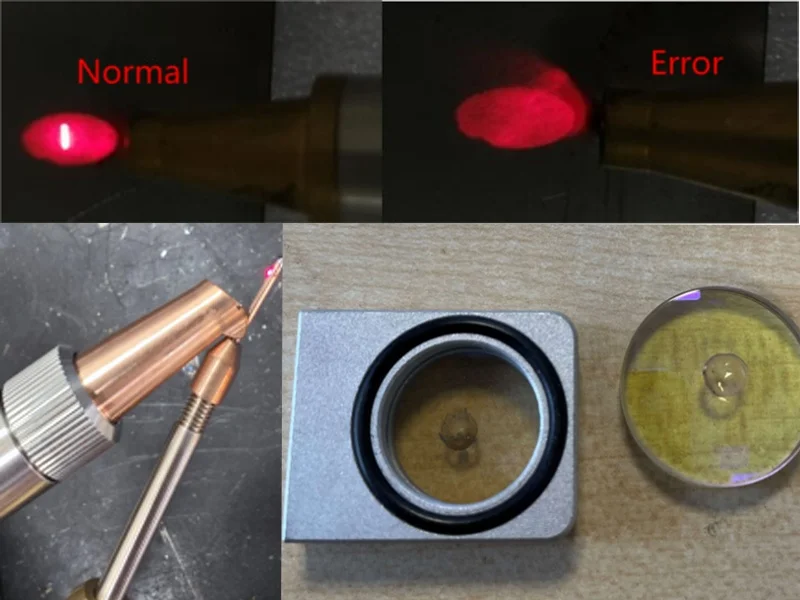

This article outlines how STRION LASER’s breakthrough technology ensures continuous and stable welding output in the face of extreme heat.

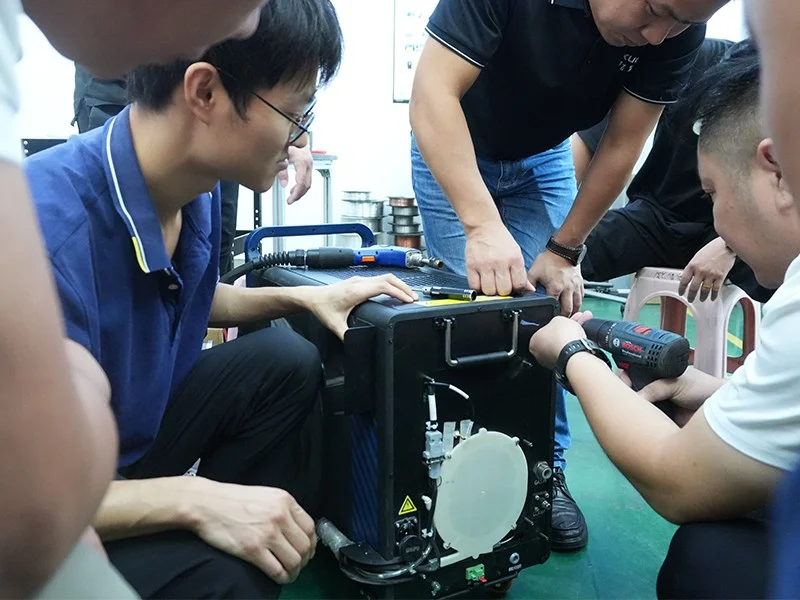

STRION LASER concluded a nationwide distributor training, boosting technical capabilities and deepening knowledge to enhance service and drive future growth.

This article provides key steps and considerations to ensure a successful aluminum alloy welding process, whether for manual, semi-automatic, or fully automated applications.

Proven in the critical field of boiler membrane wall repair, STRION LASER handheld welding has demonstrated undeniable advantages: faster construction speed, minimal deformation, superior quality, and cost savings.

Recently, Zheng Yongpeng, Deputy Secretary of the Party Working Committee and Director of the Administrative Committee of Fuping High-Tech Industrial Development Zone in Shaanxi Province, along with his delegation, visited Sichuan strongest Laser Technology Co., Ltd. for a Party building study and exchange symposium.

In this article,follow this procedure to ensure your torch operates efficiently and safely.

STRION LASER’s participation at MTA Vietnam 2025 marked a significant milestone in the company’s commitment to advancing laser welding technology.

Our latest project features automated welding of carbon steel tube-sheet assemblies, delivering high-precision results with exceptional speed and quality.

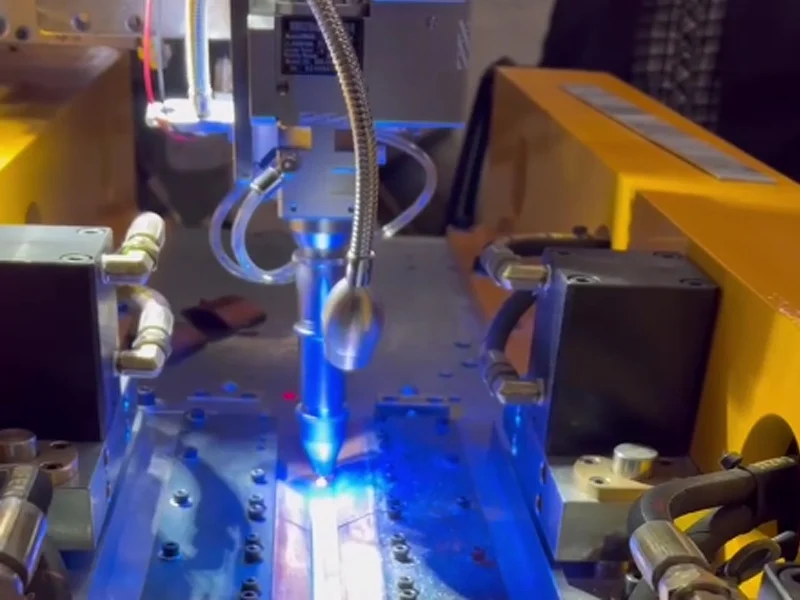

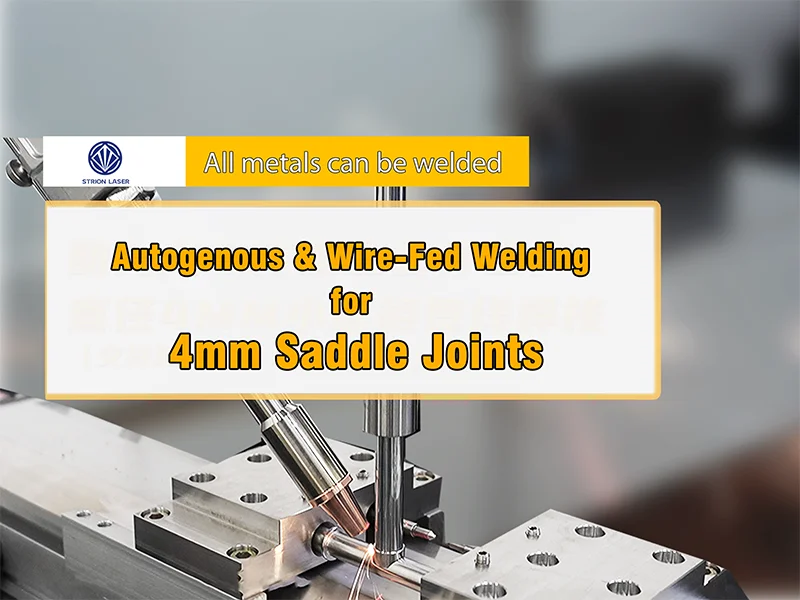

STRION LASER recently completed a successful application case of automated robotic laser welding for saddle-port thin tubes — a process requiring exceptional precision and thermal control.