News

The Top Laser Intelligent Manufacturing Expert

First-class R&D team, driving the industry’s technological innovation, the enterprise competitiveness continues to increase

News

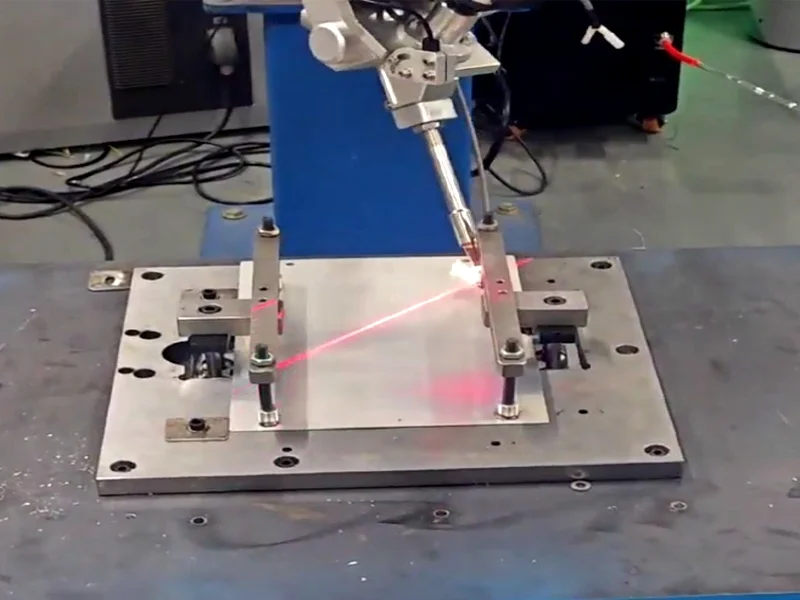

The MASTER X Series laser welder, meticulously developed by STRION LASER to meet high-quality, multi-scenario industrial demands, not only inherits the user-friendly design of the LITE S Series but also delivers a significant leap in thick-plate welding capability, meeting the rigorous requirements of heavy-duty welding applications.

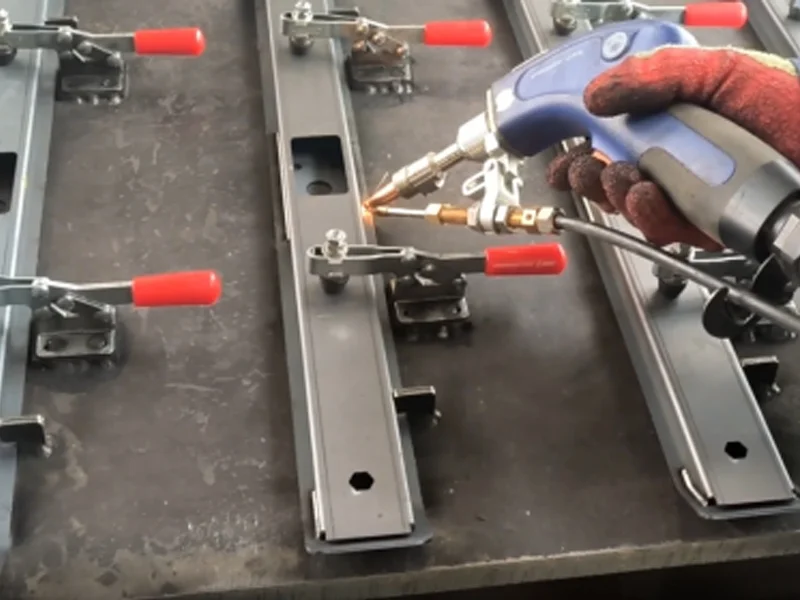

STRION LASER LITE S Series embodies continuous technological innovation and rigorous manufacturing excellence — optimizing total cost of ownership while ensuring outstanding safety and reliability.

The LITES Series high-power, coolant-cooled handheld laser welders inherit STRION LASER’s core laser technology and, addressing key customer pain points, feature innovative design optimizations that significantly enhance reliability and ease of maintenance.

Strion Laser’s LITE S Series delivers a complete solution for welding thin plates up to 4mm, combining streamlined operation, enhanced efficiency, and intelligent upgrades.

This article highlights five key factors to consider before buying a handheld laser welder, helping you make a well-informed decision that balances performance, cost, and long-term value.

This article explores the unique challenges of thin plate welding, how handheld laser welders solve them, their key advantages, applications, best practices, and what the future holds.

As an important participant in the global laser industry, STRION LASER was invited to attend 2025 “China Welding Industry Forum – Conference on Robotic and Intelligent Welding Technologies and Applications”

Handheld laser welding is an efficient and high-quality welding method. However, since it involves the use of “lasers,” many people are concerned about whether it generates radiation or poses risks to the human body.

STRION LASER has conducted in-depth research on this laser welding process and shares key practices to help manufacturers improve weld quality while reducing rework rates.

STRION LASER welding solutions are designed to directly address these pain points, offering targeted solutions that help furniture manufacturers accelerate their shift toward intelligent, efficient, and high-quality production.