News

The Top Laser Intelligent Manufacturing Expert

First-class R&D team, driving the industry’s technological innovation, the enterprise competitiveness continues to increase

News

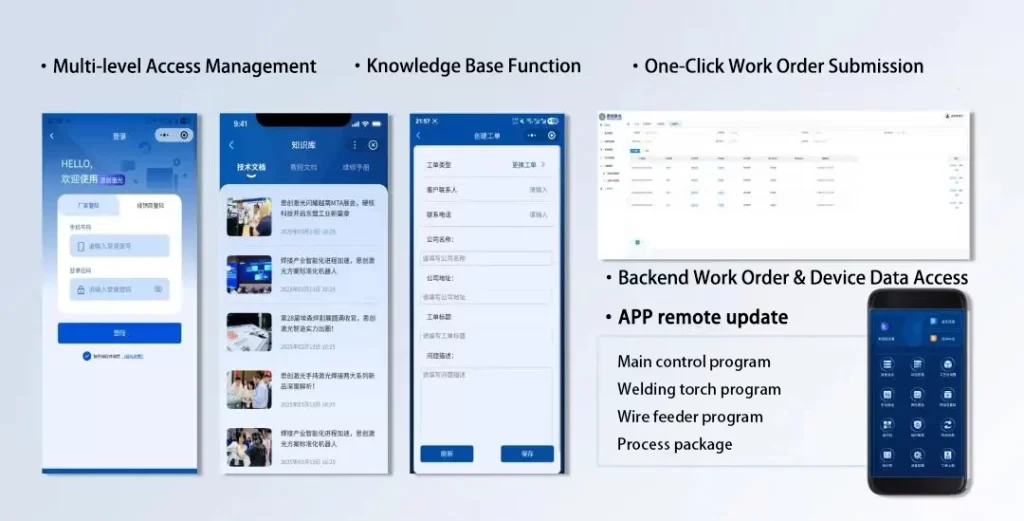

Explore how the STRION LASER Master + Lite Series delivers comprehensive system upgrades—from intelligent interaction and smart process packs to remote O&M and modular maintenance—ensuring faster, easier, and more reliable handheld laser welding.

Discover how the STRION LASER “Master + Lite” Series improves handheld laser welding reliability with an independent air-duct system, modular maintenance architecture, lightweight structure, and real-time visual monitoring for stable long-term operation.

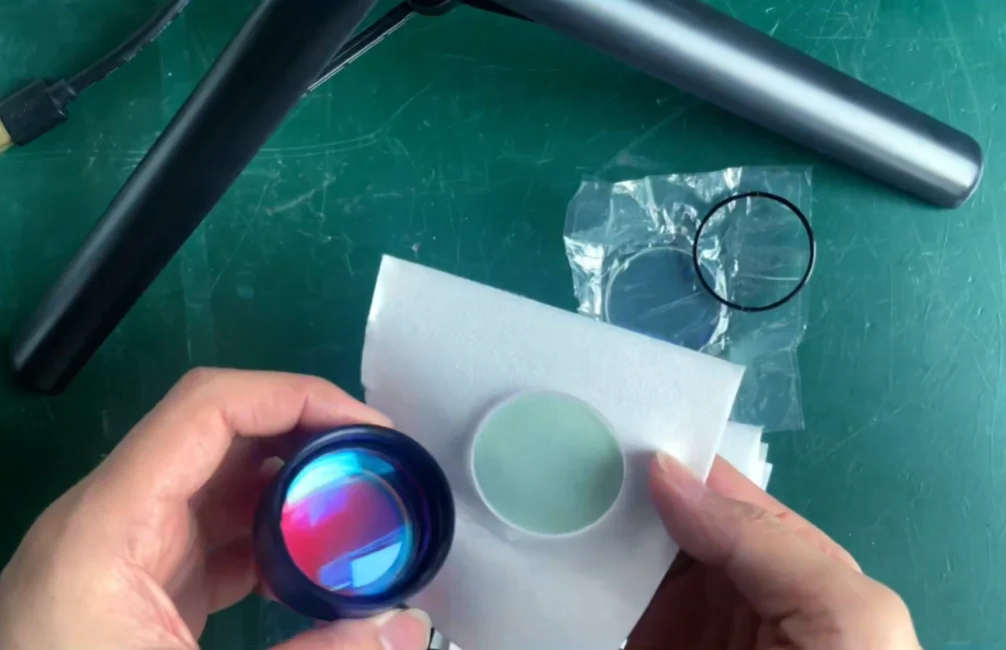

Learn how to properly replace and maintain the protective lens of the STR-iFOA laser cleaning machine. This guide covers common failures, cleaning procedures, troubleshooting steps, and installation instructions to ensure stable performance and long-term reliability.

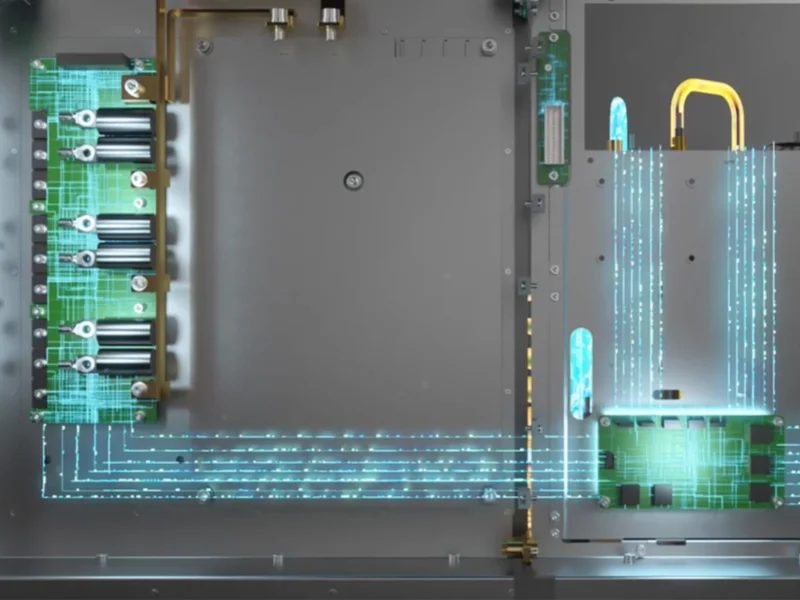

STRION LASER builds every core system in-house—including the laser source, control unit, cooling system, and welding gun—to deliver stable, long-duration welding performance with minimal downtime.

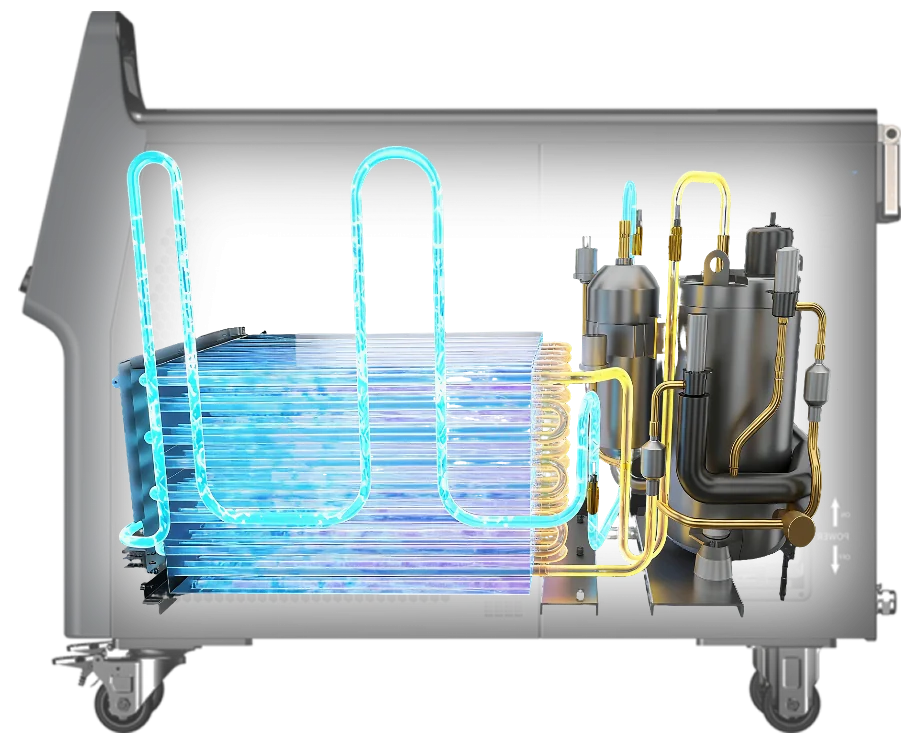

Laser welders frequently overheating, losing power, or causing unstable weld quality? STRION LASER’s aerospace-grade dual-loop refrigerant direct cooling system ensures full-power welding from −30°C to 60°C, delivering stable, efficient, maintenance-free performance.

STRION LASER has been officially recognized as a National-Level “Specialized and Innovative Little Giant” enterprise in China, showcasing its leadership in laser technology innovation, R&D excellence, and high-end manufacturing capabilities.

Discover the six core advantages of STRION LASER’s Master Series and Lite Series handheld laser welders. Featuring aerospace-grade dual-circuit cooling and next-gen laser source technology for stable, high-efficiency welding.handheld laser welder

Learn the difference between air-cooled, water-cooled, and dual-circuit refrigerant direct cooling systems in handheld laser welders. Discover which cooling solution delivers the best performance, energy efficiency, and temperature stability for your laser welding machine.

The MASTER X series expands the application scenarios of laser technology, offering industrial manufacturers flexible and efficient automation solutions, and supporting enterprises in achieving intelligent manufacturing upgrades.

This edition focuses on the equipment’s safety, reliability, interface expandability, and multi-scenario applicability, providing a comprehensive overview of the professional-grade laser welding system’s overall capabilities.