News

The Top Laser Intelligent Manufacturing Expert

First-class R&D team, driving the industry’s technological innovation, the enterprise competitiveness continues to increase

News

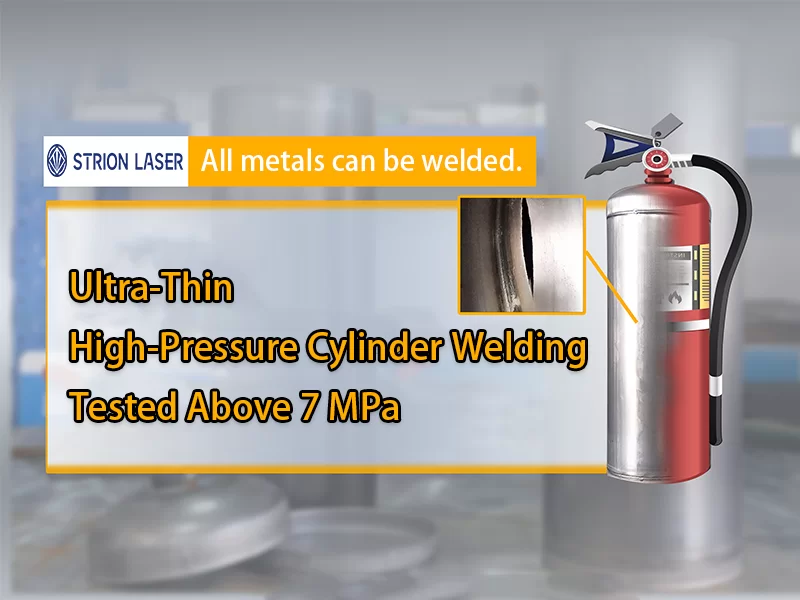

This article explains the welding requirements of fire extinguisher cylinders made of carbon steel, including material properties, pressure standards, and laser welding process parameters for stable, high-strength joints.

STRION LASER recently held its Winter Fun Sports Meet, bringing employees together through team-based activities that highlighted collaboration, engagement, and company culture.

A practical comparison of water-cooled and direct-refrigerant laser welding systems, focusing on reliability, maintenance, energy use, and five-year operating costs.

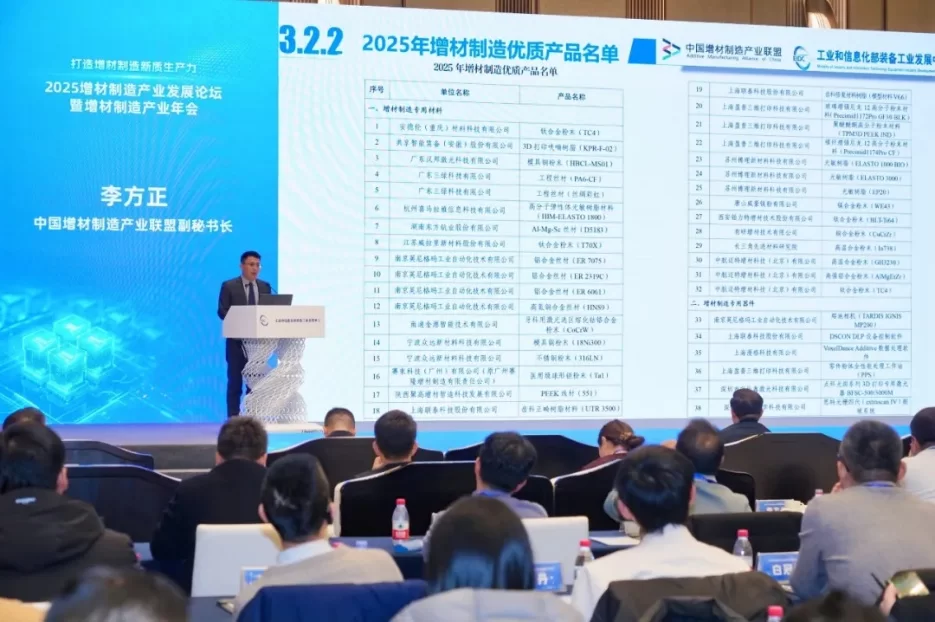

STRION LASER’s high beam quality laser source has been selected for the 2025 China Additive Manufacturing Quality Product List, recognizing its industrial performance and application reliability.

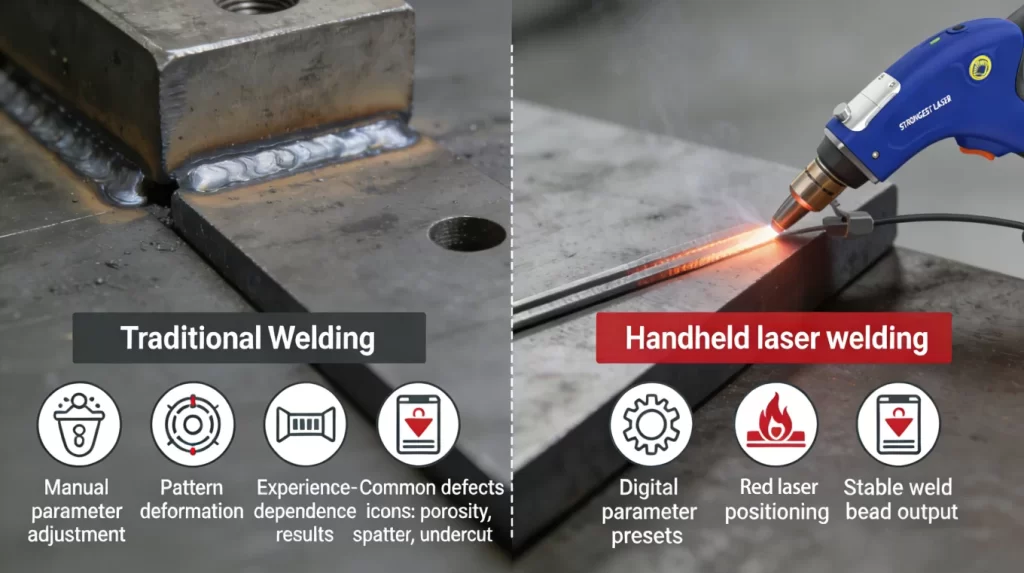

Explore and compare handheld laser welding and traditional arc/TIG welding. Understand their characteristics, performance differences, material adaptability, and application scenarios to make informed manufacturing decisions.

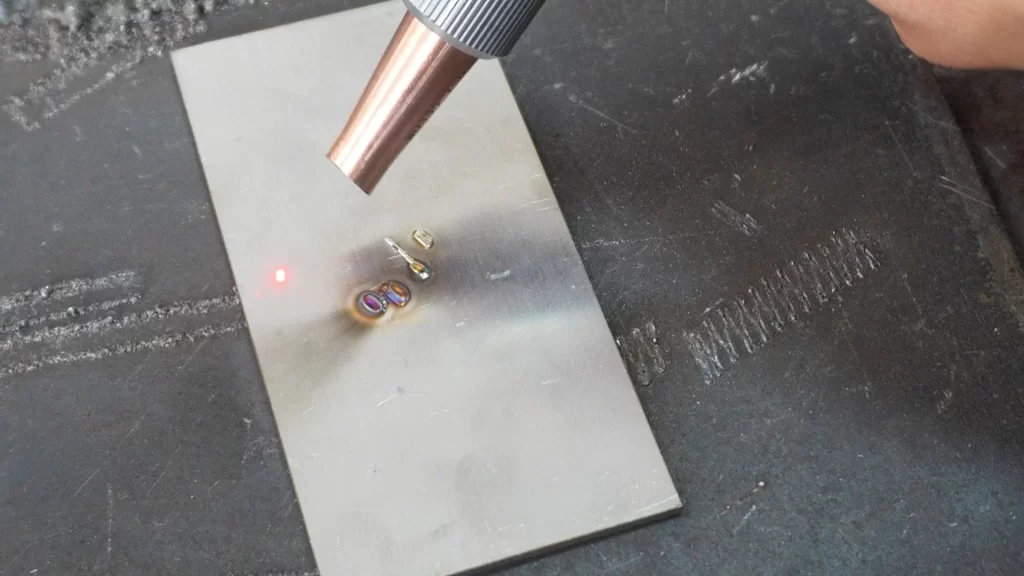

Learn how to find the correct laser welding focus point. Step-by-step guide to locating zero focus for stable penetration and consistent weld quality.

Does laser welding really fail in cold weather? This article breaks down the real reasons behind winter welding issues—and why laser technology is not the problem.

STRION LASER and the Qilu Institute of Optics sign a strategic cooperation agreement to advance optoelectronic innovation and accelerate industry–academia integration.

STRION LASER and its subsidiary SICHUAN KERUI NEW LASER TECHNOLOGY CO., LTD. have once again been certified as National High-Tech Enterprises, reaffirming their leadership in laser technology innovation.

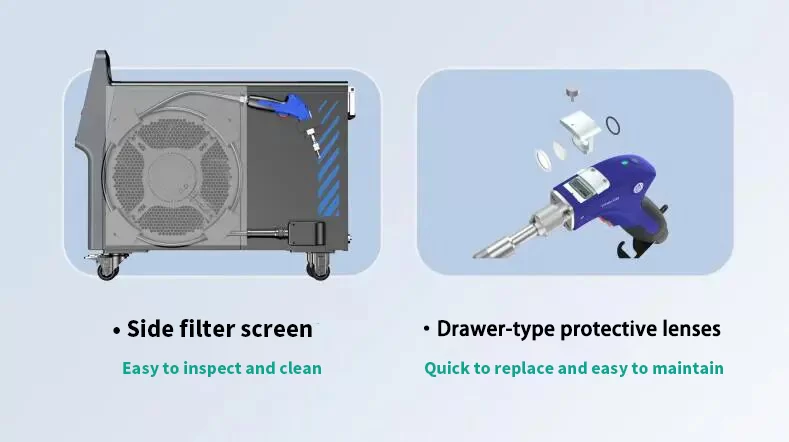

Discover how the STRION LASER Master + Lite Series delivers ultra-rugged protection through sealing architecture, voltage adaptability, refrigerant direct-cooling, and fast-maintenance design—ensuring continuous, stable laser welding even in harsh industrial environments.