STRION LASER Master + Lite Series | New Benchmark for Stable Laser Welding Productivity

In laser welding applications, the ability of equipment to operate continuously and stably under harsh conditions—high temperature, high humidity, voltage fluctuations, and heavy dust—determines production efficiency and weld quality. Many users have experienced costly downtime caused by welders unable to handle real-world environments.

The STRION LASER Master + Lite Series (Master X & Lite S) is engineered to eliminate these risks with a highly ruggedized design framework—covering sealing, electrical resilience, thermal management, and simplified maintenance.

Below are four critical stability pitfalls and how STRION LASER solves them.

Pitfall #1: Weak Environmental Protection Turns Laser Welding Into a Production Bottleneck

Common Misconception

Many laser welders claim “basic protection,” yet their sealing design is insufficient for true industrial environments, especially under heavy dust, high humidity, or outdoor conditions.

Why It Matters

In metal fabrication workshops, outdoor operations, or humid seasons, poor sealing can lead to:

- Moisture and dust intrusion

- Electrical short circuits

- Contamination of optical lenses

- Reduced cooling efficiency

- Frequent system errors and unplanned downtime

These issues directly reduce welding stability, slow production, and increase overall operating cost.

STRION LASER Solution

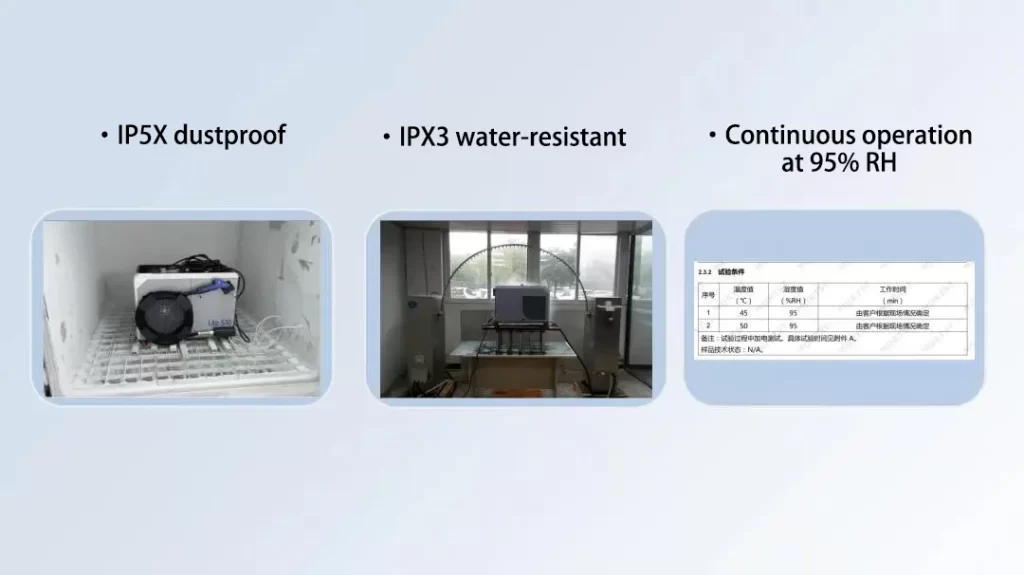

The “MASTER X & LITE S Series” is engineered for demanding environments with fully enclosed architecture and IP53-rated protection:

- Independent sealing strips across all enclosure joints

- IP5X dustproof for heavy-dust workshops

- IPX3 water-resistant against splashes and humid climates

- Reliable operation in up to 95% RHenvironments

By keeping all core components clean, dry, and isolated from environmental hazards, the DualShield Series ensures consistent laser output and long-term welding stability—no matter how challenging the workspace.

Pitfall #2: Some Laser Welding Brands Suffer from Voltage Instability and EMI, Compromising Weld Consistency

Common Misconception

Voltage instability and electromagnetic interference (EMI) are often overlooked because their impact isn’t immediately visible. Yet a laser welder with weak electrical resilience is one of the biggest hidden risks behind inconsistent weld penetration and quality fluctuations.

What Really Happens

Industrial power environments are rarely clean. Voltage dips, surges, and complex EMI can cause many welders to reboot, derate, or even fail. The result: unstable melt pools, inconsistent seams, and unpredictable performance from batch to batch.

STRION LASER Solution

The STRION LASER “Master X + Lite S” Series is engineered to remain stable in harsh electrical environments:

- Lite S Series & Master X50: Wide single-phase tolerance of 220V ±20%, capable of handling 140V–300Vfluctuations.

- Master X60 & X80: Three-phase support with 400V ±20%range, resistant to300V–500V variations.

Beyond voltage adaptability, the entire series meets the GB/T 17626 standards for surge immunity, voltage dips, EFT/burst, EMC, and ESD. Each model has passed 100,000+ high-voltage arc-discharge cycles without abnormality—ensuring stable full-power output even when the grid is unstable.

With robust electrical protection, the Master X + Lite S Series delivers consistent, repeatable weld quality across the most demanding production environments.

Pitfall #3: Some Brands Weak Cooling Systems Drive Up Long-Term Operating Costs

Common Misconception

Some laser welders on the market focus on cutting upfront cost but ignore the far bigger expense—cooling system maintenance and downtime.

Why It Matters

Industry cooling systems vary greatly:

| Cooling Method | Pros | Cons |

|---|---|---|

| Water-cooled | Good heat dissipation | Scale buildup, leak risk, freezing in winter |

| Air-cooled | Simple | Heat-soak in summer, dust accumulation |

| Refrigerant direct-cooling | High efficiency, zero intervention | Best stability, highest reliability |

Most laser welders today use one of three cooling methods, and their performance varies widely:

- Water-cooled systems:Decent heat dissipation but prone to leaks, scale buildup, frequent maintenance, and winter freeze-up issues.

- Air-cooled systems: Limited cooling capacity, easily heat-soaked in summer, and dust accumulation reduces long-term reliability.

- Refrigerant direct-cooling systems: A sealed, one-time-charge design that eliminates scaling, freezing, and dust issues. With higher cooling efficiency and zero routine intervention, it is increasingly the preferred choice for stable, high-power welding.

STRION LASER Solution

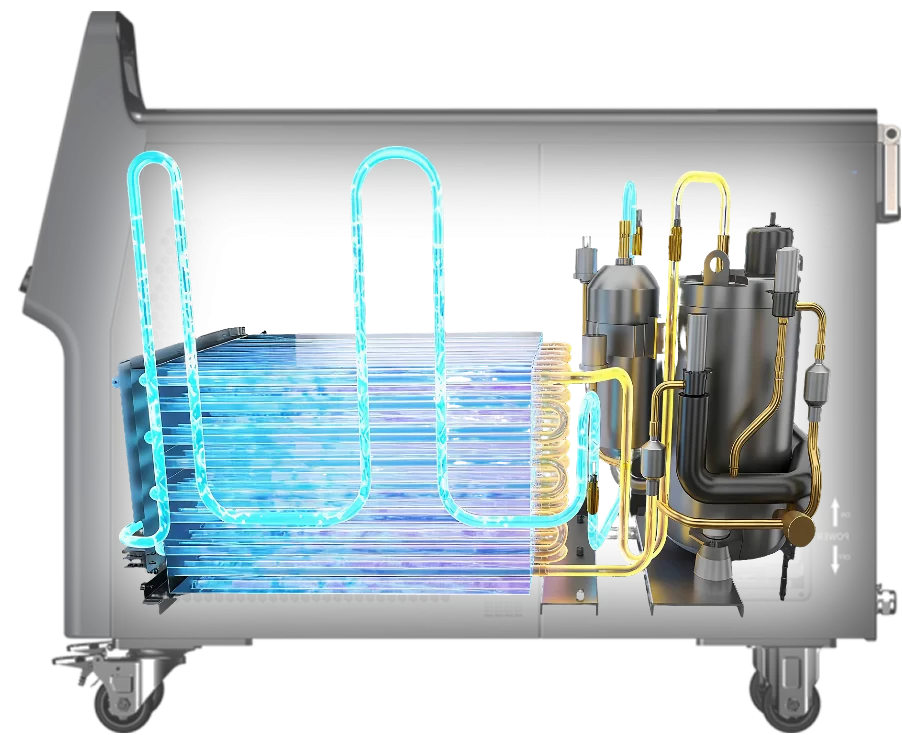

The STRION LASER “Master X + Lite S” Series is equipped with an aerospace-grade dual-loop refrigerant direct-cooling system, engineered in-house.

Think of it as giving your laser welder an industrial-grade variable-frequency air-conditioning system:

- Operates reliably from -30°C to 60°C

- Extracts heat directly from core components with high precision

- Maintains peak performance in all seasons

- Fully sealed with no coolant replacement, no antifreeze, no routine maintenance

The result is a highly stable cooling platform that cuts maintenance time, extends equipment lifespan, and lowers total cost of ownership—ideal for factories seeking long, uninterrupted production.

Pitfall #4: Some Brands Cumbersome Daily Maintenance Eats Into Real Production Time

Common Misunderstanding

Many manufacturers underestimate how much time and labor routine maintenance consumes over a machine’s full lifecycle. Over time, this “hidden burden” becomes a major drag on overall productivity.

Why It Matters

Some laser welders on the market have poor designs around filter access, lens replacement, and dust management. As a result:

- Maintenance frequency increases

- Operators spend more time on non-productive tasks

- Overall equipment utilization drops

STRION LASER Solution

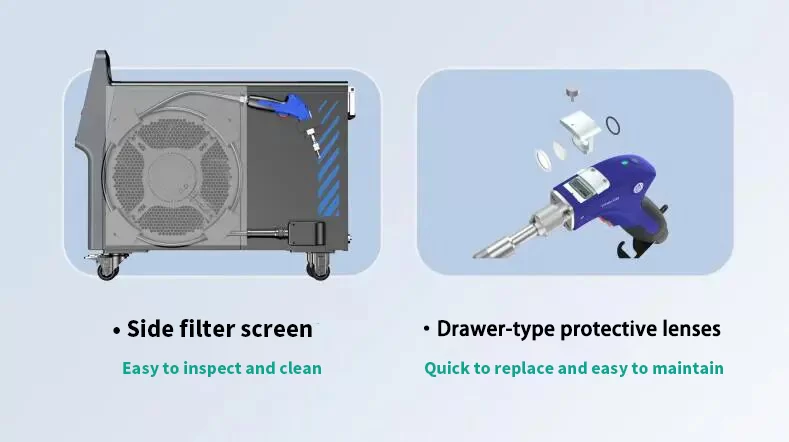

The STRION LASER “Master X + Lite S” Series is engineered for fast, effortless maintenance:

- Side-mounted filtersare easy to access, inspect, and clean—ensuring stronger dust protection with less effort

- Drawer-type protective lenses can be replaced in seconds without tools or specialist skills

- Optimized internal layoutreduces maintenance points and shortens downtime

The result: smoother daily operations, less interruption, and more hours spent on actual production.

Built for Harsh Conditions. Engineered for Continuous Production.

The STRION LASER Master + Lite Series delivers unparalleled stability through comprehensive protection architecture—ensuring uninterrupted welding, consistent output, and lower total operating cost.

This is the new benchmark for dependable, high-stability handheld laser welding.

Contact STRION LASER

📞 +028-85812068

🌐 www.strlaser-en.com

📧 str@strlaser.com