STRION LASER “Master + Lite” Series: A New Structural Design for High-Reliability Handheld Welding

In industrial environments where dust, mobility constraints, and unpredictable workload are common, laser welding equipment must deliver more than power—it must remain stable, durable, and easy to maintain.

To address these real-world challenges, STRION LASER introduces the “Master + Lite” Series, engineered with a new-generation structural design that elevates the reliability of handheld welding systems.

This updated architecture focuses on four major innovations: air-duct protection, modular maintenance, lightweight mobility, and real-time visual monitoring.

1. Independent Air-Duct Protection: Dust-Free Operation for Long-Term Stability

The STRION LASER “Master + Lite” Series adopts an independent side-air-duct design that fully separates cooling airflow from the internal optical chamber.

All core optical components operate in a sealed environment, effectively blocking external dust intrusion.

With a left-in, right-out airflow layout, the system:

- Increases the heat-dissipation area

- Shortens the duct path

- Reduces airflow resistance

Testing shows that the new airflow design boosts cooling efficiency by 50%, allowing the equipment to maintain a stable operating temperature during continuous welding.

This significantly extends the service life of the optical components.

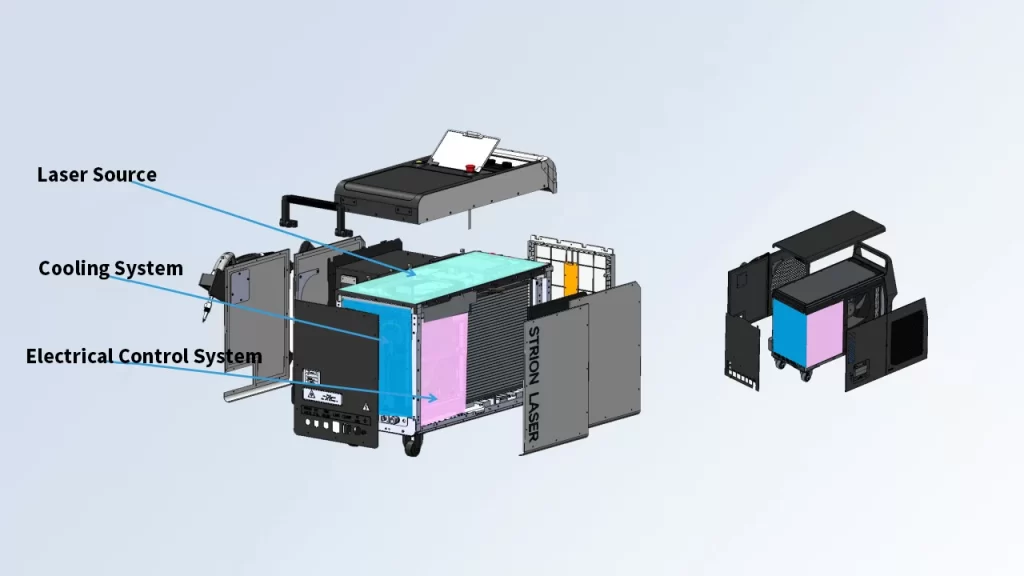

2.Modular Maintenance Design: Simplified Workflow, Lower Service Costs

The STRION LASER “Master + Lite” Series features a zoned modular architecture, with:

- Electrical control system

- Optical engine

- Cooling system

All independently enclosed.

This design allows maintenance to focus on a specific module without cross-system interference.

An independently sealed optical chamber further enhances protection and eliminates contamination risks.

With these upgrades, overall equipment lifespan is extended by 50%, ensuring long-term stable operation while reducing maintenance complexity and operating costs.

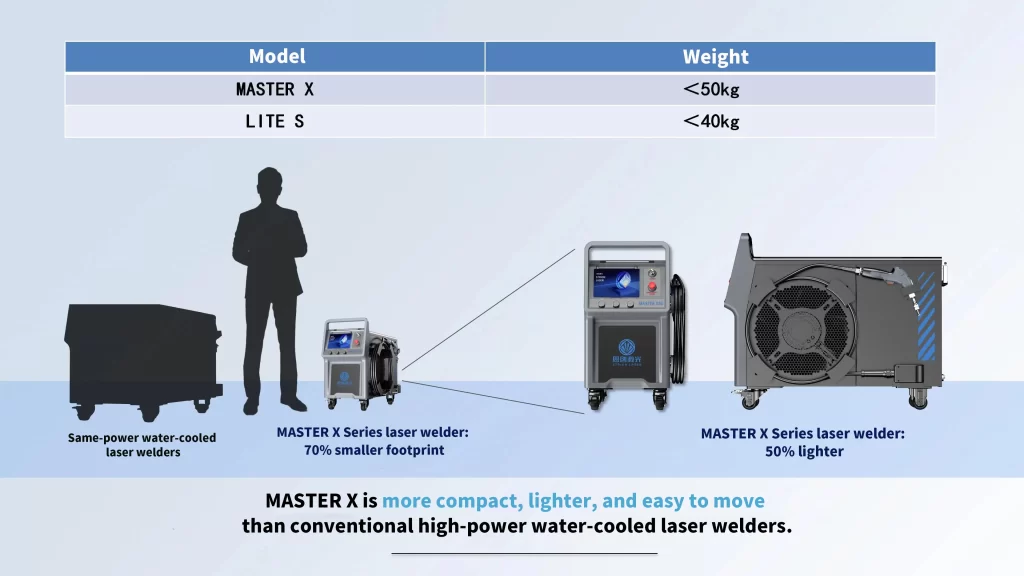

3.Lightweight Structural Design: Enhanced Mobility for Diverse Environments

Through an optimized internal layout and the use of high-strength lightweight materials, the STRION LASER “Master + Lite” Series achieves:

- 70% reduction in size

- 50% reduction in weight

compared with conventional high-power water-cooled welders—without compromising performance.

Ergonomic handles and 360° swivel casters come standard, enabling efficient and effortless movement.

A single operator can easily push, position, and deploy the machine, making it ideal for workshops, construction sites, and other scenarios requiring flexible on-site welding.

4.Visual Monitoring System: Real-Time Status and Intuitive Safety Alerts

The STRION LASER “Master + Lite” Series features high-visibility safety indicator lights that use multiple colors and flashing patterns to clearly display equipment status.

Operators can scan and identify the status within 0.5 seconds, allowing early detection of abnormalities and fast response.

This design integrates safety monitoring into daily workflows, making equipment status immediately visible and preventing production interruptions or damage caused by delayed anomaly detection.

Built to Last, Ready for Any Challenge

Choosing the STRION LASER “Master + Lite” Series means opting for long-lasting reliability and peace of mind.

Crafted with precision and care, each machine becomes a trusted partner on your production line, delivering consistent high-quality performance you can depend on.

Contact STRION LASER

📞 +028-85812068

🌐 www.strlaser-en.com

📧 str@strlaser.com