Welding is an essential process in modern manufacturing, used to join materials and create strong, durable bonds. Among the many welding techniques available today, laser welding and TIG (Tungsten Inert Gas) welding stand out as two of the most widely used methods. Both technologies are valued for their precision and versatility but differ significantly in their processes, applications, and advantages. This article will compare laser welding and TIG welding in terms of their performance, benefits, and real-world applications, helping you make an informed decision about which method is best suited to your needs.

1. What is Laser Welding?

Laser welding is a high-precision technique that uses a focused laser beam to melt and fuse materials. The laser’s intense heat can be concentrated on a small area, allowing for extremely fine welds with minimal distortion. In laser welding, the laser beam acts as the heat source, providing the energy needed to melt the material at the joint. A handheld laser welding machine or automated laser welding system typically directs the laser to the welding site, ensuring accuracy and repeatability.

Key features of laser welding systems include:

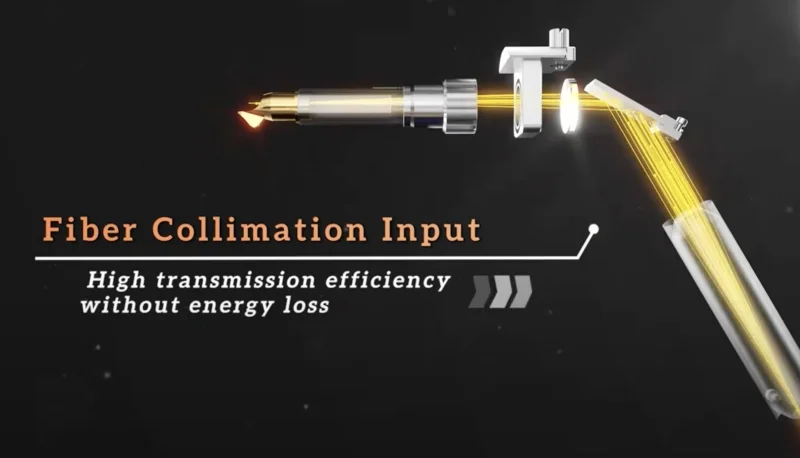

- Laser Source: The laser beam is typically generated by a solid-state or fiber laser.

- Precision: Laser welding allows for extremely fine control over the weld, making it ideal for delicate or small parts.

- Automation: Laser welding systems are highly compatible with automation, offering higher efficiency in mass production.

Advantages of Laser Welding:

- Speed: Laser welding is much faster than traditional welding techniques, especially in high-volume manufacturing.

- Precision: The process can produce very small, precise welds, often with minimal post-weld finishing.

- Minimal Heat-Affected Zone (HAZ): The focused nature of the laser beam results in less heat dispersion, reducing distortion and damage to surrounding materials.

- Suitability for Thin Materials: Laser welding excels in welding thin metals and can be used on materials that would be difficult to weld with other methods.

2. What is TIG Welding?

TIG welding, also known as Gas Tungsten Arc Welding (GTAW), uses a non-consumable tungsten electrode to generate an arc of heat. The arc melts the base material and filler rod, which is added to form the weld. An inert gas, typically argon, is used to shield the weld area from contamination, ensuring a clean and strong bond.

Key features of TIG welding systems include:

- Tungsten Electrode: The electrode creates the arc that melts the base material.

- Argon Gas Shielding: The shielding gas prevents oxidation and contamination during the welding process.

- Manual Control: TIG welding offers significant control over the heat input, which is crucial for delicate materials and precise welds.

Advantages of TIG Welding:

- High Precision: TIG welding allows for excellent control over the welding process, particularly in thin or intricate parts.

- Control Over Heat Input: The welder can adjust the arc and filler material, providing great flexibility for various types of metals.

- Versatility: TIG welding can be used on a wide range of materials, including stainless steel, aluminum, and titanium, making it suitable for diverse applications.

3. Key Differences Between Laser Welding and TIG Welding

| Aspect | Laser Welding | TIG Welding |

| Speed & Efficiency: | Much faster, especially in automated environments. Ideal for high-volume production. | Slower, more suited for custom and small-batch jobs. |

| Precision & Quality: | Finer focus, smaller, more controlled welds. | High aesthetic quality, suitable for visual appeal. |

| Material Compatibility: | Can weld a wider range of materials, including dissimilar metals (Stainless steel, carbon steel, aluminum, copper, galvanized steel, etc.). | Best for stainless steel, aluminum, and titanium. |

| Heat Input & Distortion: | Produces less heat, reducing the risk of distortion. | Provides control over heat input, but excessive heat may cause distortion. |

| Automation & Cost Efficiency: | Greater potential for automation, reducing labor costs and improving consistency in mass production. | More manual, suitable for custom work or small batches. |

4. Advantages of Laser Welding Over TIG Welding

Laser welding offers several advantages over TIG welding, particularly when speed and automation are critical:

- Faster Weld Speeds: The efficiency of laser welding is especially beneficial in automated production environments, where high-speed welding is needed.

- Ability to Weld Complex Geometries: Laser welding can be easily applied to complex and hard-to-reach areas, making it ideal for intricate designs.

- Lower Energy Consumption: Laser welding is more energy-efficient, which reduces overall operational costs.

- Higher Repeatability and Automation: The precision of laser welding, combined with its automation potential, results in consistent, high-quality welds.

- Less Post-Weld Cleanup: Due to the small heat-affected zone, laser welding often requires less rework after the welding process.

5. Advantages of TIG Welding Over Laser Welding

While laser welding is advantageous in many high-speed and mass-production scenarios, TIG welding shines in other areas:

- Superior Control: TIG welding offers unmatched control, especially for fine, delicate parts where precision is crucial.

- Versatility: TIG welding can be used in various positions (e.g., vertical, overhead), making it ideal for custom or repair jobs.

- Lower Initial Investment: TIG welding equipment is typically less expensive and simpler to set up than laser welding systems.

- Ideal for Custom & Repair Work: For custom fabrication and repair work, TIG welding’s manual nature allows for adjustments to ensure a high-quality finish.

6. Applications of Laser Welding

Laser welding is most commonly used in industries where precision and speed are critical:

- Automotive: Laser welding is used for producing lightweight, high-strength components, such as battery packs and body parts.

- Aerospace: The aerospace industry benefits from laser welding’s precision and ability to work with high-performance materials.

- Electronics: Laser welding is used for assembling delicate electronic components where small, precise welds are required.

- Medical Instruments: Laser welding provides high precision for welding medical instruments, including surgical tools and devices where hygiene and accuracy are critical.

- Hardware Products and Building Materials: Laser welding is commonly used for joining metal parts in hardware products and construction materials, offering high strength and durability in large-scale fabrication.

- Furniture and Electrical Appliances: Stainless steel furniture, electrical appliance casings, and other household items benefit from the precision and speed of handheld laser welding.

- Mass Production: Laser welding is well-suited to high-volume manufacturing environments, offering rapid, consistent results.

7. Applications of TIG Welding

TIG welding is valued in industries requiring high-quality, visually appealing welds:

- Aerospace: Used for welding critical parts that require high strength and precise welds.

- Medical Devices: TIG welding is commonly used to weld stainless steel and titanium parts, ensuring strength and cleanliness for medical applications.

- Piping and Tanks: TIG welding is ideal for creating strong, clean welds in piping systems and storage tanks.

- Custom Fabrication: TIG welding excels in custom projects where manual control and attention to detail are required.

8. Conclusion

In summary, both laser welding and TIG welding have their strengths and are suited to different applications. Laser welding excels in speed, precision, and automation, making it ideal for high-volume production and complex parts. TIG welding, on the other hand, offers superior control, versatility, and is well-suited for custom and small-batch applications requiring high-quality, aesthetic welds.

When choosing between the two methods, consider factors like material type, required precision, production volume, and cost. As welding technologies continue to evolve, both methods are likely to see improvements, making them even more efficient and accessible for a broader range of industries.

STRONGEST LASER, with its core competence in high-power fiber laser technologies, stands at the forefront of the laser welding industry. Our company has dedicated itself to continuous research and development, producing cutting-edge equipment for conventional laser welding, special laser hybrid welding, and precision cutting applications. As a “National High-Tech Enterprise,” STRONGEST LASER excels in delivering high-quality, efficient, and precise welding solutions. Our advanced laser welding systems offer numerous advantages, including faster processing speeds, superior precision, and the ability to weld a wide range of materials, including dissimilar metals. With reduced heat input and minimized distortion, STRONGEST LASER’s technology ensures high-quality welds while maintaining structural integrity, making it an ideal choice for high-volume production and applications that demand precision and reliability.

If you are looking for a suitable welding solution, welcome to consult the STRONGEST LASER for free. We will provide you with customized services according to your application requirements.