Why Your Laser Welds Lack Strength (And How to Fix It) | STRION LASER

Laser welding has become a core process in modern manufacturing, valued for its precision, speed, and clean weld appearance. It is widely used across industries—from small metal workshops to heavy machinery production.

Despite these advantages, many operators and manufacturers encounter a persistent challenge: insufficient weld strength. Weak welds can lead to rework, quality complaints, and, in serious cases, structural or safety risks.

As a company deeply involved in laser welding technology development, STRION LASER has gained extensive hands-on experience through long-term cooperation with manufacturers in different industries. Based on this practical insight, and supported by the technical characteristics of the MASTER X Series and LITE S Series handheld laser welders, this article examines the real causes of low laser welding strength and outlines proven, practical methods to improve weld reliability—helping you achieve strong, durable, and consistent weld joints suitable for industrial applications.

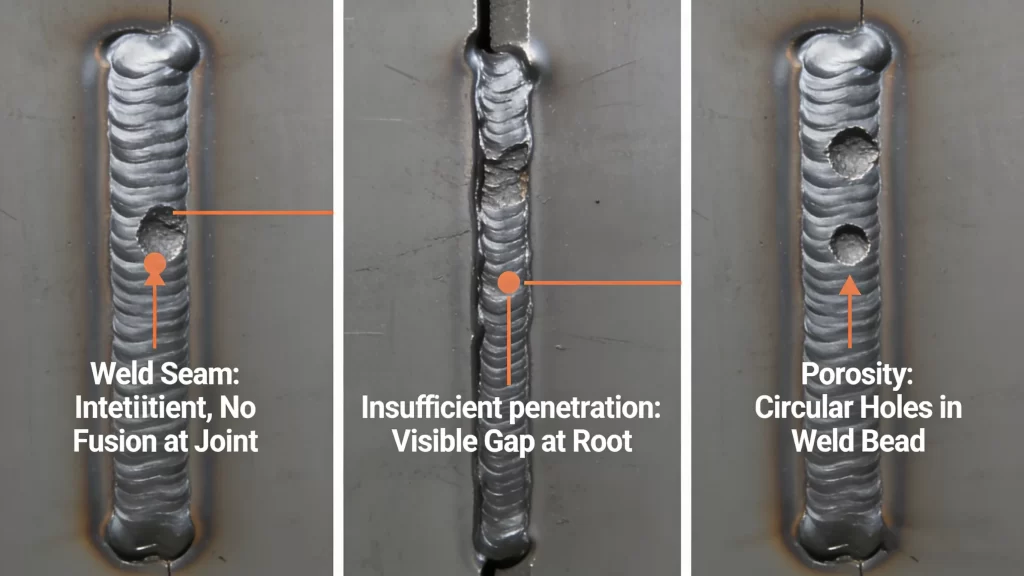

Common Causes of Insufficient Laser Welding Strength

Before troubleshooting, it is essential to identify the root cause. In most cases, weak laser welds can be traced back to a few recurring factors related to parameter settings, operating habits, or material preparation. Among them, the most common issues include the following.

1. Incorrect Parameters Resulting in Insufficient Penetration

Laser welding parameters—such as laser power, welding speed, focal position, and wire feeding speed—directly determine penetration depth and fusion quality. A frequent mistake is relying on “experience-based settings” instead of adjusting parameters to match the actual workpiece, which often leads to problems such as:

- Low power combined with high speed

The laser energy does not fully penetrate the material, creating a surface-level weld without proper fusion between layers. - Improper focal distance

If the welding head is positioned too far from or too close to the workpiece, energy density drops, reducing penetration depth. - Mismatched wire feeding speed

Excessive wire feed causes incomplete melting, while insufficient feed can result in gaps or weak seam formation.

To address this issue, STRION LASER welders—from the entry-level LITE S30 (900W) to the high-power MASTER X80 (3000W)—are equipped with over 20 built-in process presets. Each preset is calibrated for specific materials such as stainless steel, carbon steel, and aluminum, as well as for different thickness ranges. This allows operators to start from optimized parameters rather than guesswork, significantly reducing the risk of weak weld joints caused by improper settings.

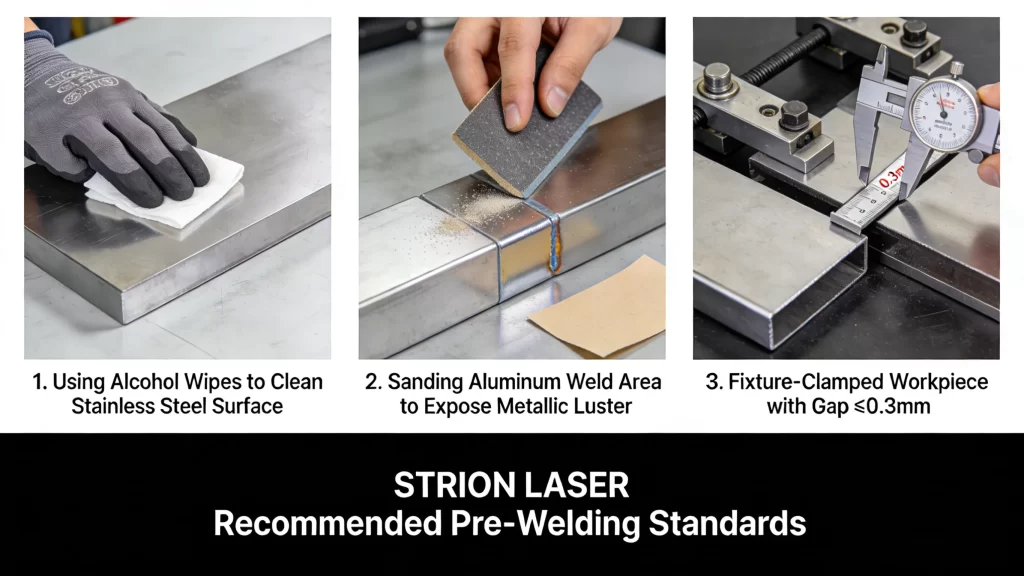

2. Improper Workpiece Preparation: Contamination and Poor Fit-Up

Even the most advanced laser welding equipment cannot compensate for inadequate workpiece preparation. Surface contamination and improper assembly are often overlooked, yet they are among the most common hidden causes of weak welds.

- Oil, rust, or oxide layers

During welding, these contaminants burn and release gases, creating pores or inclusions inside the weld seam. This directly compromises structural integrity and reduces joint strength. - Excessive assembly gaps

Gaps larger than 0.3 mm prevent molten metal from filling the joint evenly, leading to incomplete fusion and reduced load-bearing capacity. - Poor alignment between parts

Uneven contact surfaces cause irregular stress distribution along the weld, increasing the risk of localized weakness or early failure.

In one real case, a small stainless steel fabrication workshop using a STRION LASER LITE S40 reported inconsistent weld strength. After inspection, the issue was traced not to the machine, but to residual oil on the workpiece surface. Once a standardized pre-weld cleaning process was implemented—using acetone for degreasing and a wire brush to remove oxidation—the weld strength increased by approximately 40%, with no changes made to the welding parameters or equipment.

3. Inadequate Shielding Gas Protection Leading to Oxidation

Most metals—such as aluminum, carbon steel, and stainless steel—are highly susceptible to oxidation at welding temperatures. Without effective shielding gas protection, the molten pool reacts with oxygen in the air, forming brittle oxide layers that significantly reduce weld toughness and joint strength.

Common issues include:

- Insufficient gas flow

When shielding gas flow (typically argon) is too low, it fails to fully cover the molten pool, allowing ambient air to enter the weld zone. - Incorrect gas nozzle position

If the nozzle is positioned too far from the weld or held at an improper angle, gas coverage becomes unstable and uneven, reducing its protective effect. - Poor shielding gas quality

Contaminated or low-purity gas containing moisture or impurities can introduce porosity and internal defects into the weld seam.

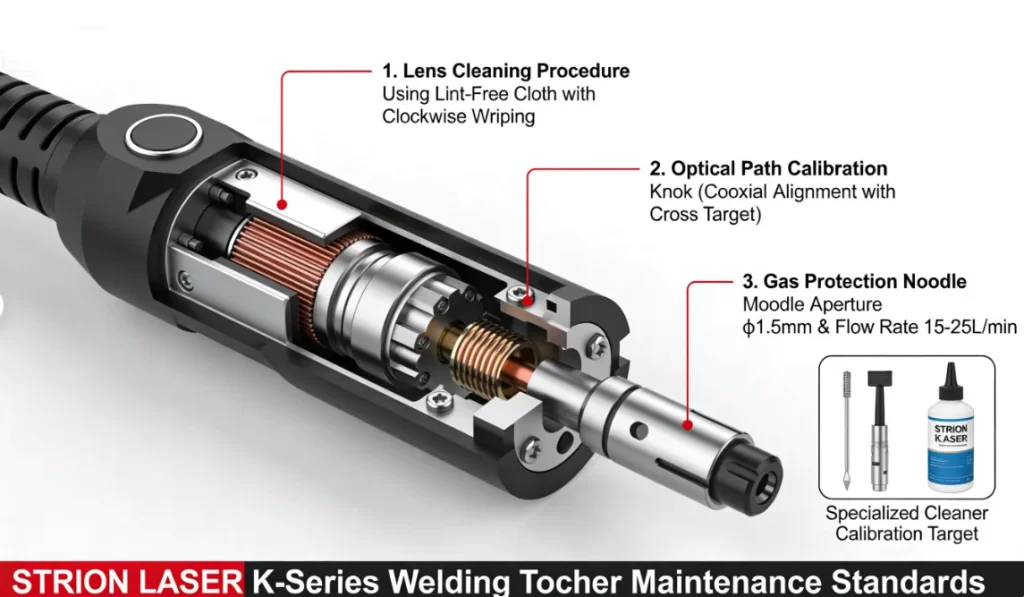

STRION LASER’s self-developed K-Series welding torch is designed to address these issues through an optimized gas protection structure. The integrated air-knife system helps keep optical components clean while delivering consistent, uniform shielding gas coverage over the weld area. Its ergonomic design enables operators to maintain a stable nozzle-to-workpiece distance—typically 3–5 mm—ensuring reliable protection, which is especially critical when welding high-reflectivity materials such as aluminum.

4. Declining Equipment Performance or Poor Maintenance Practices

Over time, insufficient maintenance can lead to reduced laser output stability, which directly affects weld penetration and joint strength. This issue is often overlooked but plays a critical role in long-term welding quality.Typical causes include:

- Contaminated or damaged optical components

Spatter, dust, or scratches on the protective window and focusing lens reduce laser transmission efficiency. Even minor contamination can lower effective power at the weld point, resulting in shallow penetration and weak welds. - Laser power degradation beyond normal levels

While STRION LASER systems are designed with an annual power attenuation rate below 1%, improper operation—such as prolonged overheating—can accelerate power loss and compromise weld consistency. - Uncalibrated wire feeding systems

An unstable wire feed, whether from single or dual feeders (e.g. STR-WFS-A or STR-WFD-A), leads to uneven filler metal distribution, causing inconsistent fusion and reduced mechanical strength.

STRION LASER handheld laser welders are engineered for easy maintenance and long-term reliability. The K-Series welding torch allows fast replacement of protective windows and focusing lenses without special tools. The dual-circuit refrigerant direct cooling system prevents thermal overload and helps maintain stable laser output during extended operation. By routinely cleaning optical components with lint-free wipes and alcohol, and periodically checking wire feed calibration, users can preserve weld strength, extend equipment lifespan, and maintain consistent production quality.

5. Ignoring Material Characteristics and Proper Welding Practices

Different materials behave very differently during laser welding. Overlooking these differences is a common reason for weak welds:

- Highly reflective materials (aluminum, copper)

These materials reflect a large portion of laser energy, requiring higher power density and controlled welding speed to achieve proper fusion. STRION LASER’s high beam quality fiber laser sources are optimized for reflective metals, reducing energy loss and improving penetration stability. - Thick workpieces

Using low-power equipment on thick materials—such as 8 mm stainless steel or 10 mm carbon steel—often results in incomplete penetration. The MASTER X80 (3000W) is designed for this scenario, delivering sufficient energy for single-pass welding without compromising joint strength. - Incorrect welding mode selection

Applying spot welding where continuous welding is required (or vice versa) leads to uneven stress distribution and reduced mechanical strength. STRION LASER handheld laser welders support both spot and continuous welding modes, allowing operators to select the correct process for each application.

Understanding material behavior and following basic welding process rules ensures that laser energy, heat input, and fusion depth are properly balanced—laying the foundation for strong, reliable welds.

Practical Ways to Improve Laser Weld Strength

Once the root causes are clear, improving weld strength becomes a matter of targeted adjustments and correct use of the equipment. Below are practical methods that help unlock the full potential of STRION LASER handheld welders:

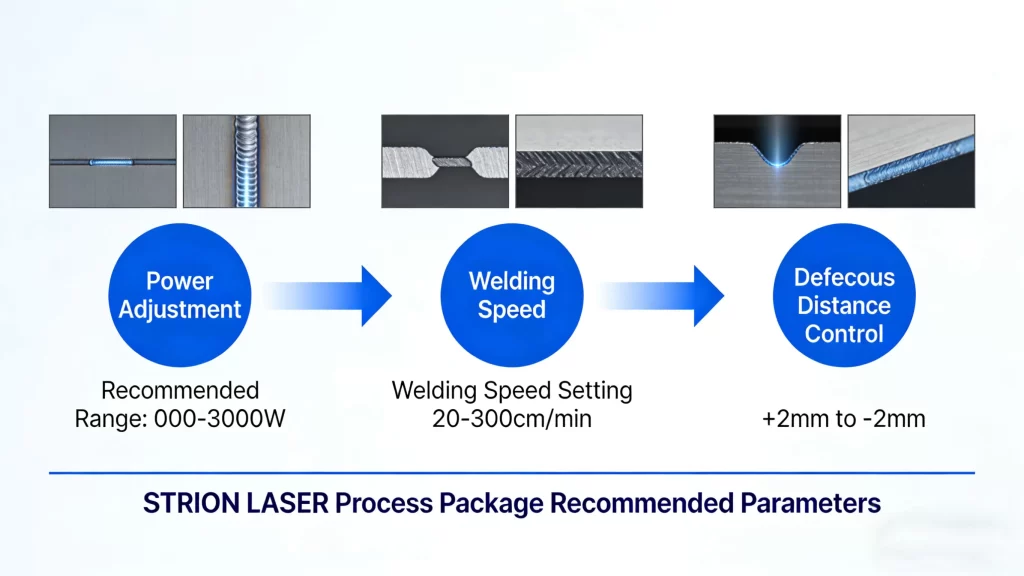

1. Optimize Parameters Based on the Workpiece

- Start with built-in process presets

STRION LASER machines come with pre-configured welding programs matched to common materials and thicknesses. For example, when welding 3 mm carbon steel with the LITE S30 (900W), a proven setup is around 800W power, 120 cm/min welding speed, and +2 mm defocus, delivering stable penetration without excess heat input. - Fine-tune gradually, not aggressively

If penetration is insufficient, increase laser power by 5–10% or reduce welding speed by 10–15%. Small, controlled adjustments help improve fusion while avoiding spatter or distortion. - Match wire feed speed to power level

Wire feed must stay in balance with heat input. For example, when welding 5 mm carbon steel with 1.2 mm filler wire, a feed speed of 60–80 cm/min pairs well with 1500W output (MASTER X50), ensuring proper melting and strong joint formation.

Correct parameter matching transforms laser energy into consistent penetration and reliable fusion—laying the groundwork for stronger, more durable welds.

2. Standardize Workpiece Preparation

Proper preparation is the foundation of weld strength. Even small oversights before welding can significantly weaken the final joint.

- Thorough cleaning before welding

Remove oil, grease, rust, and oxide layers using solvents such as acetone or ethanol, or mechanical methods like wire brushing or sandblasting. A clean surface ensures stable melting and prevents porosity. - Control joint fit-up and alignment

Keep assembly gaps below 0.3 mm whenever possible. Use fixtures or clamps to hold parts firmly in place and maintain consistent alignment throughout the weld. - Apply preheating when required

For thick steel or high-carbon steel components, preheating to 100–200°C helps reduce thermal stress, improves fusion, and lowers the risk of cracking after cooling.

3. Improve Shielding Gas Protection

Effective gas shielding prevents oxidation and directly affects weld toughness and consistency.

- Use high-purity shielding gas

Select argon with a purity of 99.99% or higher. Impure gas introduces moisture and contaminants that lead to porosity and reduced weld strength. - Set the correct gas flow rate

For handheld laser welding, a flow rate of 15–25 L/min is typically sufficient to fully protect the molten pool without causing turbulence or unnecessary gas consumption. - Maintain proper nozzle position

Keep the gas nozzle perpendicular to the weld seam, with a distance of 3–5 mm from the workpiece surface. This ensures stable coverage of the molten pool and minimizes oxidation.

4. Perform Regular Equipment Maintenance

Consistent maintenance is essential to keep laser output stable and ensure repeatable weld quality.

- Clean optical components weekly

Wipe the protective window and focusing lens with a lint-free cloth moistened with isopropyl alcohol. This removes spatter and dust that can reduce laser energy transmission. - Check laser power output monthly

Use a power meter to verify actual output. If power loss exceeds 5%, contact STRION LASER technical support for inspection or calibration. - Inspect the wire feeding system

Ensure the wire conduit is free of kinks, and confirm that drive rollers are clean and properly tensioned to prevent slipping or inconsistent feeding.

5. Apply Proper Welding Techniques for Different Materials

Each material responds differently to laser welding. Adjusting techniques accordingly is critical for achieving high weld strength.

- For aluminum alloys

Use higher power, slower travel speed, and positive defocus (for example, +3 mm). A 2000W MASTER X60 is recommended for welding 6 mm aluminum to ensure sufficient energy absorption. - For thick plates

Apply multi-pass welding when necessary, overlapping each pass by approximately 50% to achieve full penetration and uniform fusion. - For high-strength steels

Select matching filler wire, such as ER70S-6 for carbon steel, to maintain weld strength consistency with the base material.

Conclusion: Getting Stronger Laser Welds

Weak laser welds are rarely caused by a single problem. In most cases, they result from incorrect parameters, poor surface preparation, or lack of proper maintenance. By addressing these basics and using a stable, well-designed welding system, consistent and reliable weld strength can be achieved.STRION LASER’s MASTER X Series and LITE S Series are engineered for real production environments, offering stable power output, optimized process presets, and reliable performance from –30°C to 60°C. Combined with proper welding techniques, they help workshops and manufacturers produce stronger, more durable welds.For application-specific advice or parameter support, visit www.strlaser-en.com or contact STRION LASER at +86-28-85812068. Our technical team is ready to help you improve weld quality and production efficiency.