Laser Welding “Fails” Every Winter? Let’s Stop Blaming the Technology.

If you’ve searched for “winter laser welding problems” or “laser welding malfunctions in cold weather,” you’re not alone.

Slow startup, frequent alarms, unexpected shutdowns—and lengthy, frustrating after-sales disputes.

These are the real-world losses caused by equipment that is “not cold-resistant,” and problems that users encounter every winter.

At STRION LASER, we understand these pain points.Therefore, today we want to clarify misconceptions about equipment stability and demonstrate how manufacturers can completely solve the problem of production downtime during winter.

01. Aerospace-Grade Dual-Loop Direct Refrigerant Cooling

Putting an End to “Seasonal” Production Downtime

In today’s laser welding market, many cooling solutions come with clear limitations.

Water-cooling systems, while widely used, carry inherent risks such as leakage and scale buildup. In harsh winter conditions, they are even more prone to slow start-ups, reduced circulation efficiency, and in extreme cases, frozen pipelines.

Air-cooling systems, on the other hand, offer limited heat dissipation capacity. Their performance drops significantly under high temperatures, and dust accumulation further compromises long-term stability—making them unsuitable for sustained high-power welding applications.

To address these challenges, STRION LASER has developed and integrated an in-house, aerospace-grade dual-loop direct refrigerant cooling system.

Much like an industrial-grade inverter air conditioner for laser equipment, this system ensures fast start-up and stable operation across an extreme temperature range—from –30 °C to 60 °C—effectively eliminating seasonal downtime risks.

By using a direct refrigerant cooling approach, STRION LASER welding systems remove heat efficiently and directly from critical components, enabling precise temperature control and significantly higher cooling efficiency.

This design fundamentally eliminates common failure points such as scale buildup, freezing, and dust accumulation, which often plague conventional cooling solutions.

With its high reliability and low maintenance requirements, the system stands out as a truly practical choice for applications that demand long-term stability and high-reliability welding performance.

02 . Fully In-House Designed and Manufactured

Eliminating the Compatibility Risks of “Assembled” Systems

Sudden shutdowns, interrupted production lines, followed by long troubleshooting cycles caused by poor compatibility between multi-brand components—this should not be part of your daily operation.

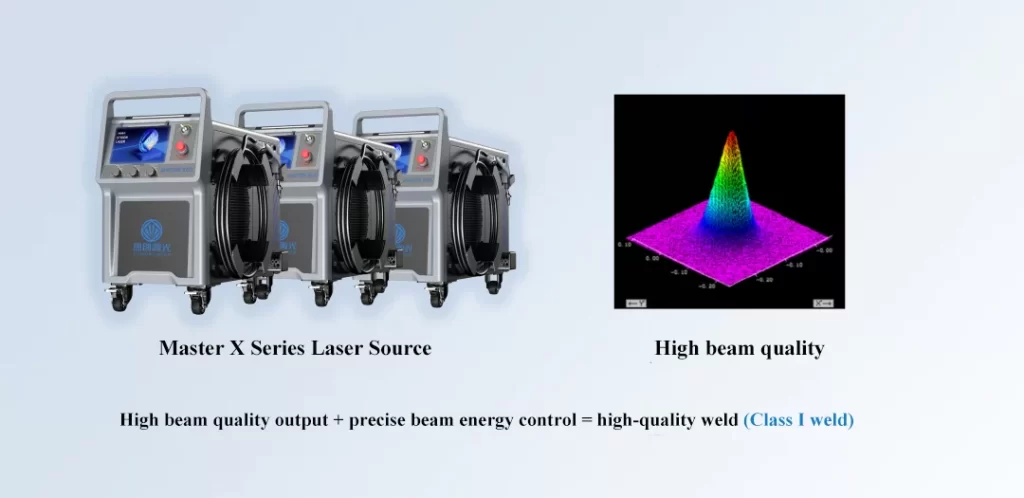

At STRION LASER, we insist on 100% in-house design and manufacturing to ensure full-system coordination and reliability from the ground up. By independently developing our laser sources and core optical components, we achieve longer optical path lifespans and more stable energy output, fundamentally reducing the likelihood of system failures.

Our proprietary small-core, high-brightness laser source further optimizes beam output characteristics. By combining high beam-quality single-mode output with precise energy control, energy is highly concentrated in the welding zone, significantly increasing energy density and enabling deeper, more consistent penetration.

This technology demonstrates excellent process adaptability when welding highly reflective materials, effectively suppressing back-reflection and ensuring stable long-term operation.As a result, the STRION LASER MASTER X80 series achieves a maximum penetration depth of up to 12 mm—approximately 30% deeper than conventional systems—and is fully capable of producing Class I weld seams, meeting the stringent requirements of industries such as shipbuilding and aerospace.

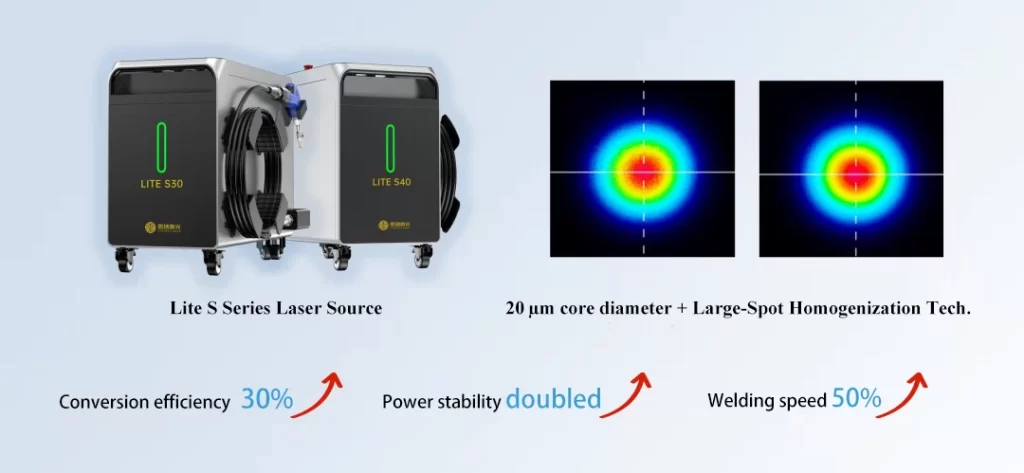

The newly developed large-spot beam homogenization technology ensures uniform heat distribution across the welding zone, significantly reducing workpiece deformation caused by localized overheating.

This balanced thermal profile enables stable weld formation even at high welding speeds.As a result, weld seams are smooth and consistent, with spatter greatly reduced, achieving an effective balance between welding efficiency and finished product quality.

03. The “Weld Guardian” Service System

Turning Commitments into Measurable Support

At STRION LASER, professionalism is defined by the ability to deliver on promises.

Through a nationwide service network, internationally certified quality standards, and a closed-loop, full lifecycle service system, we provide customers with fast response, dependable support, and long-term operational security.

From installation and commissioning to maintenance and technical optimization, every stage is designed to reduce uncertainty and ensure stable production—so you can focus on output, not after-sales concerns.

Contact STRION LASER

📞 +028-85812068

🌐 www.strlaser-en.com

📧 str@strlaser.com