According to projections by China Merchants Securities, the laser welding equipment industry is poised to exceed 30 billion yuan in market value by 2025, driven largely by demand from the power battery sector, which is expected to contribute approximately 20 billion yuan to this growth.

Over the past few years, advances in laser technology—particularly in semiconductor and fiber lasers—have significantly improved welding capabilities while reducing costs. These developments have broken through traditional technical barriers, opening up new applications and markets for laser welding.

Major players in the laser welding market include global names like Germany’s IPG, and leading Chinese equipment suppliers such as Han’s Laser, HGTech, Hymson, and United Winners Laser. Additionally, specialized laser manufacturers such as Raycus, Maxphotonics, and Feibo Laser have also introduced laser welding products, including handheld laser welders. Among them, STRONGEST LASER stands out as a key innovator and market leader in China.

1. Distinct Advantages of Laser Welding Drive Increasing Market Penetration

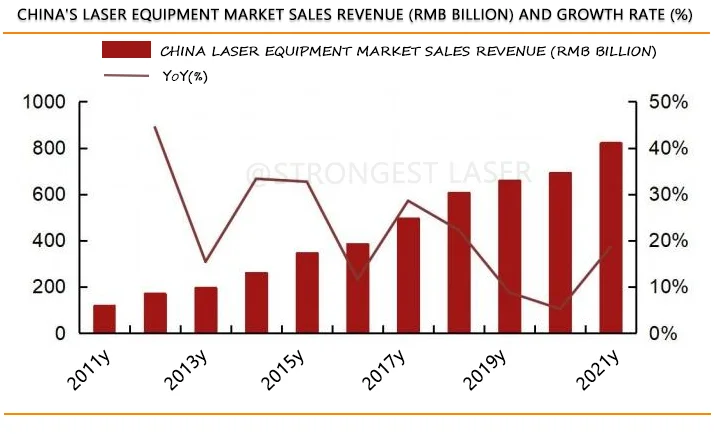

Laser welding is set to become the primary direction for the next phase of technological advancement in laser processing. As a representative of emerging technologies, the laser industry has shown strong growth over the past decade. According to the China Laser Industry Development Report, global laser equipment sales reached USD 21 billion in 2021 and have continued to grow steadily year over year. The laser welding market alone is expected to exceed 30 billion yuan by 2025. As an advanced and innovative processing method, laser welding is entering its “golden decade” of rapid development.

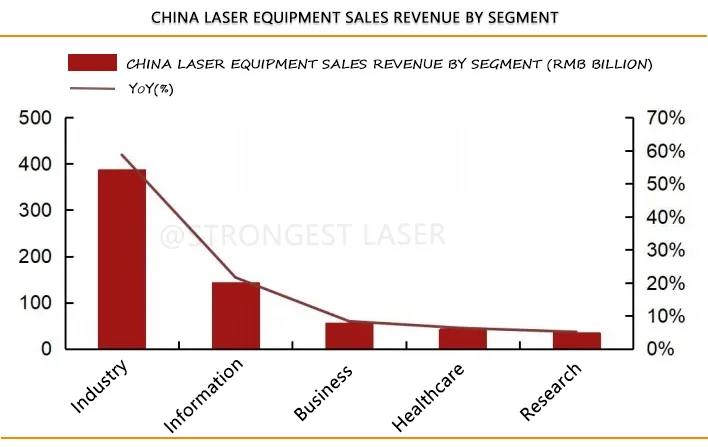

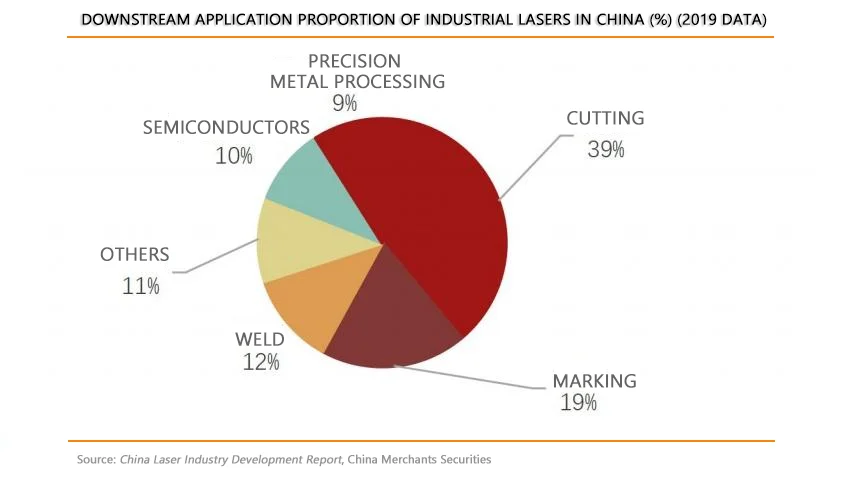

Among all laser equipment, approximately 60% is used for industrial processing. Welding is one of the key application scenarios in the laser industry, utilizing high-energy-density laser beams as a heat source for efficient and precise joining. In terms of technological advancement, China’s laser equipment industry has made continuous breakthroughs along the path of marking, sheet metal cutting, welding, and micro-nano processing. Currently, the technologies for marking and sheet metal cutting are relatively mature, with innovation cycles beginning to plateau. In contrast, welding and micro-nano processing are expected to lead the next wave of technological evolution in laser processing.

According to statistics, only 12% of industrial lasers in China were used for welding as of 2019—a figure significantly lower than the 39% used for cutting. However, the proportion of lasers used for welding is expected to rise to around 20% in the coming years. This forecast is based on several key factors:

2. Laser welding offers significant advantages over traditional welding techniques in terms of precision, efficiency, and adaptability

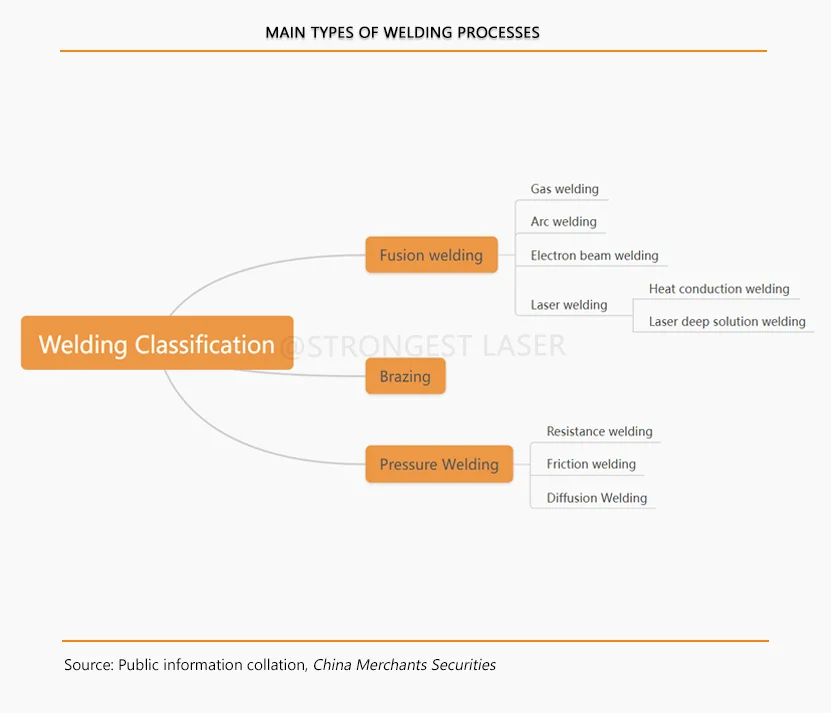

Welding is one of the most common methods for joining materials. Based on the underlying mechanism, welding can be classified into three main types: fusion welding, pressure welding, and brazing:

Fusion Welding: This method involves melting a portion of the base material to form a weld pool, which solidifies into a weld seam. Heat sources include combustion gases like acetylene, electric arcs, lasers, and electron beams. Laser welding in lithium battery manufacturing, for example, falls under fusion welding.

Brazing: This method joins metals by heating both the filler metal (with a melting point lower than that of the base materials) and the base materials to a temperature where the filler melts but the base materials do not. The liquid filler flows into the joint gap and solidifies upon cooling. Depending on the filler’s melting point, brazing is categorized as soft brazing (below 450°C) or hard brazing (above 450°C). Fusion welding heat sources can often be used for brazing as well, along with other methods such as hot air and high-frequency induction heating.

Pressure Welding: This technique involves applying pressure to the workpieces, causing plastic deformation at the interface to form a solid-state bond. Common types include resistance welding, friction welding, diffusion welding, and ultrasonic welding.

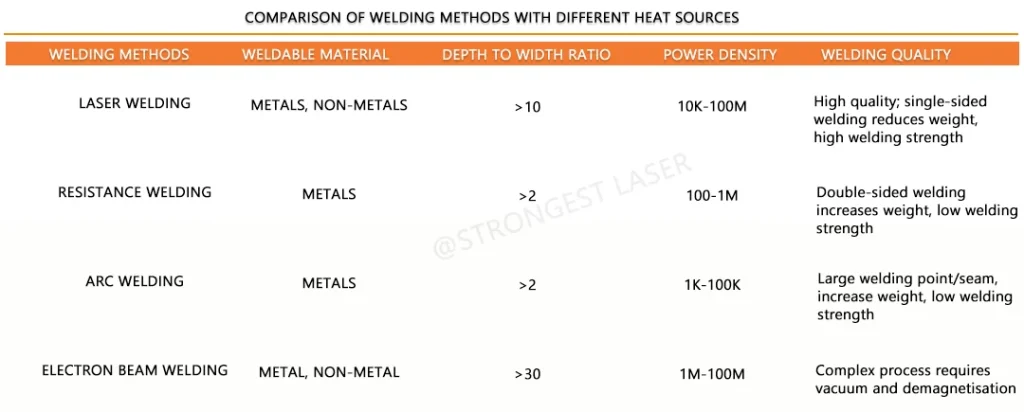

Laser welding is primarily used for fusion welding, and in some cases, it can serve as a heat source for brazing, though it is rarely used for pressure welding. Compared to traditional welding processes, laser welding offers the following characteristics and advantages (using STRONGEST LASER as an example):

Wider Material Compatibility:Laser welding is suitable not only for welding carbon steels but also for non-ferrous metals like aluminum and copper. It is particularly effective for materials that require high precision, such as thin aluminum sheets. The STRONGEST LASER STR-HW200 series, for instance, can achieve precision as fine as 0.2mm.

Larger Depth-to-Width Ratio:Laser welding has a higher power density, enabling STRONGEST LASER to achieve a depth-to-width ratio of over 10 times. This high-power laser provides superior welding strength for thick plates compared to resistance welding.

Smaller Thermal Distortion: The higher power density of laser welding results in narrower welds and smaller heat-affected zones. Additionally, since laser welding is a non-contact process, thermal distortion during welding is minimized.

Higher Welding Quality:Under proper gas shielding, laser welds exhibit higher quality, with significantly stronger joint strength than arc welding or resistance welding.

3.The Cost-Effectiveness of Laser Welding is Gradually Improving

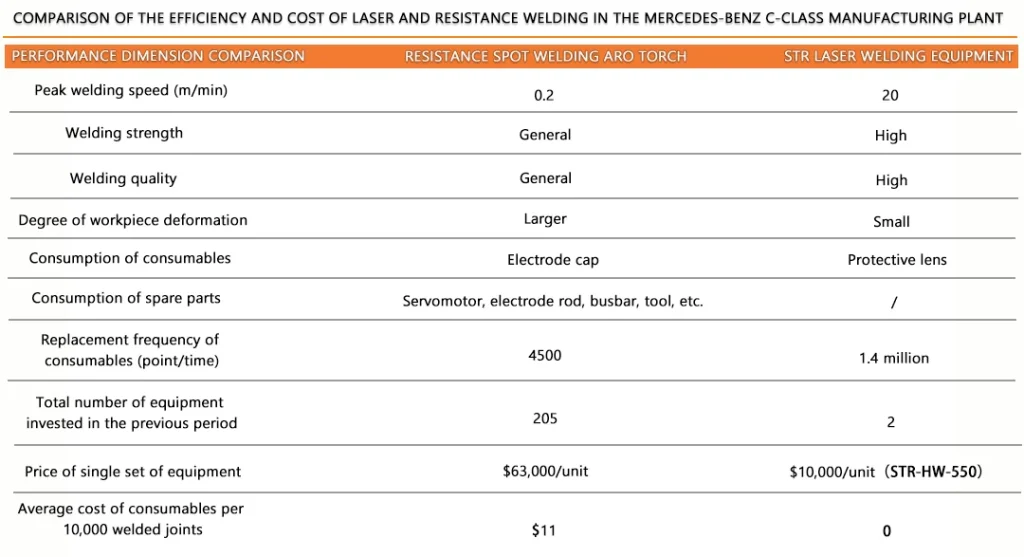

From a cost perspective, the initial investment required for laser welding equipment is high, which has been a major factor limiting the widespread adoption of laser welding. According to a report from Electric Welding Machine magazine, a comparison was made between the costs of laser welding and resistance welding in the manufacturing of Mercedes-Benz C-Class cars. The plant in question is equipped with 205 sets of resistance spot welding machines and 2 sets of STRONGEST LASER welding equipment. The comparison is as follows:

Welding Efficiency:Laser welding significantly outperforms resistance welding in terms of speed. The STRONGEST LASER welding speed can reach 2 meters per minute, while resistance welding operates at 0.2 meters per minute. Ideally, one laser welding robot can achieve the same efficiency as 10 resistance welding robots.

Consumable Costs: The consumable costs for resistance welding are notably higher than those for laser welding. Resistance welding requires consumables like servo motors, electrode rods, busbars, and tools, with an average consumable cost of $12 for every 10,000 spot welds. In contrast, laser welding uses very few consumables, mainly the protective lenses. In the case of manufacturing a car body, approximately 1,000 to 5,000 weld points are needed. Assuming a factory produces 60,000 white bodies per year, with 3,000 weld points per vehicle, the total number of weld points would be 180 million. If all of these points were welded using resistance welding, the consumable cost would be $200,000 annually. This would result in an average consumable cost of about $976 per resistance welding robot per year.

Initial Purchase Cost: The initial purchase cost for laser welding equipment is significantly higher than for resistance welding. The average price of a laser welding robot on the international market is $196,000 per unit, which is approximately three times the cost of a resistance welding robot and about twice the cost of an arc welding robot. In practice, the setup cost for laser welding robots is also higher. Assuming a 10-year depreciation period, the annual depreciation cost for each laser welding robot and resistance welding robot is $19,600 and $6,300, respectively, resulting in a difference of $13,300 per year. This difference is still far greater than the annual consumable cost of $976 per resistance welding robot.

In summary, while the initial purchase cost of laser welding equipment is higher, the overall cost-effectiveness of laser welding improves due to its higher efficiency and lower consumable costs over time.