Laser Spot Welding 1mm Stainless Steel: Clean Surface, No Burn-Through

Laser spot welding is widely used for thin stainless steel parts where appearance, heat control, and joint strength are all critical. However, welding 1mm stainless steel can be challenging if heat input is not properly controlled.

In this application demo, we show how controlled laser spot welding achieves a clean, bright surface weld with no backside discoloration, while still delivering reliable mechanical strength.

Why Spot Welding Thin Stainless Steel Is Difficult

Thin stainless steel is highly sensitive to heat. Excessive energy can easily cause burn-through, backside oxidation, or distortion of the base material. At the same time, insufficient energy may result in weak bonding.

The real challenge lies in balancing heat input, not increasing power.

How Controlled Laser Spot Welding Solves These Issues

Instead of driving energy deep into the material, controlled laser spot welding focuses heat on the surface. By carefully managing laser power, pulse timing, and wobble width, the weld forms quickly and efficiently without overheating the backside.

This approach allows the material to bond properly while maintaining a clean appearance.

Laser Welding Parameters Used in This Demo

This demonstration was performed using the STRION LASER Lite S Series.

- Material: Stainless steel

- Thickness: 1 mm

- Laser power: 25%

- Laser frequency: 35 Hz

- Wobble width: 0.5 mm

- Laser on-time: 10 ms

- Interval time: 20 ms

These parameters are optimized to concentrate energy at the weld surface while minimizing thermal impact.

Welding Results: Appearance and Strength Test

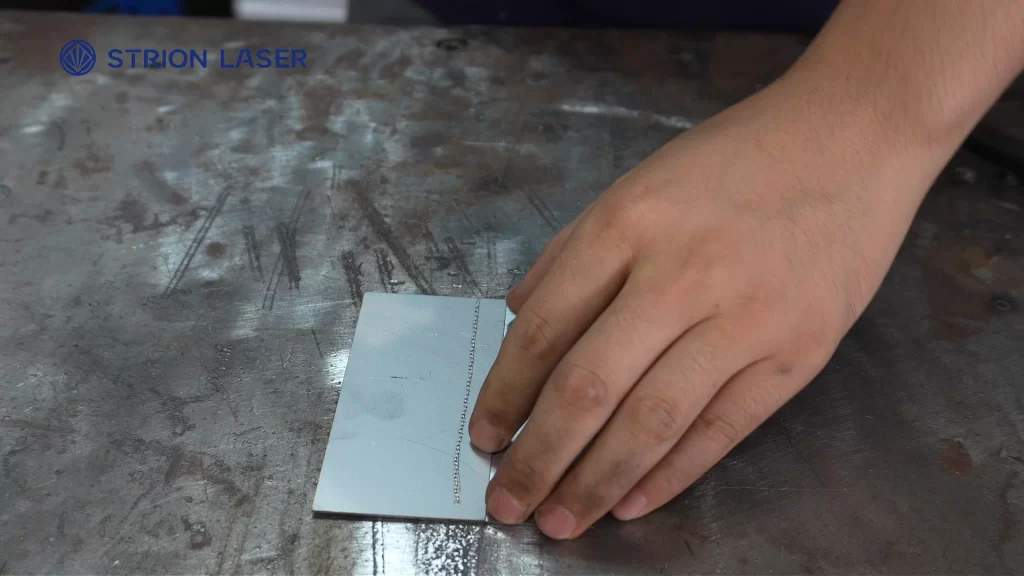

From the front, the weld seam appears bright, smooth, and uniform.

On the backside, there is no discoloration, indicating excellent heat control.

During strength testing, the base metal showed clear deformation, while the weld itself remained intact — confirming that this spot welding method provides dependable strength.

Applications for Laser Spot Welding on Stainless Steel

This type of clean, controlled spot welding is ideal for:

- Sheet metal enclosures and housings

- Stainless steel panels and brackets

- Precision assemblies where appearance matters

Conclusion

High-quality laser spot welding is not about maximum power, but about precise control. With the right parameters and a stable laser system, it is possible to achieve clean surfaces, no burn-through, and reliable strength on 1mm stainless steel.

The STRION LASER Lite S Series demonstrates a practical and repeatable solution for modern stainless steel fabrication.

Contact STRION LASER

📞 +028-85812068

🌐 www.strlaser-en.com

📧 str@strlaser.com