Surface cleaning and preparation are critical processes across industries such as automotive, aerospace, construction, food production, and cultural heritage restoration. The right cleaning method improves efficiency, protects valuable equipment, and ensures compliance with quality standards. Among the many options available, three methods stand out: laser cleaning, dry ice blasting, and sandblasting.

Each has unique strengths, limitations, and applications. In this article, we’ll compare how they work, their effectiveness, environmental impact, cost, and safety considerations. Whether you’re evaluating a laser cleaning machine, considering dry ice blasting, or relying on sandblasting, this guide will help you identify the best solution for your needs.

How Each Method Works

Laser Cleaning

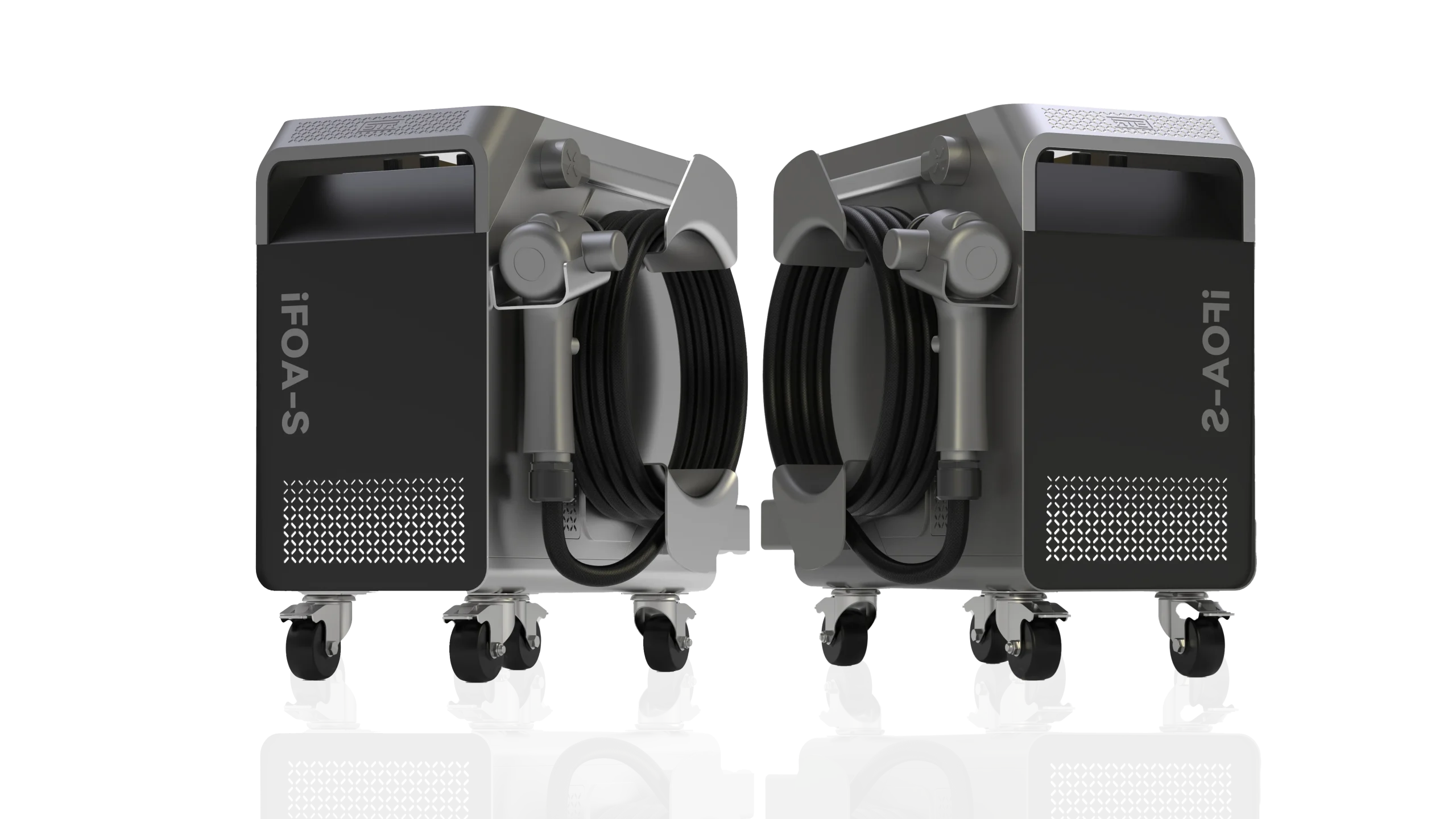

Laser cleaning uses high-intensity laser pulses directed at a surface to remove contaminants such as rust, paint, oxides, or grease. The beam generates enough energy to vaporize or ablate unwanted material without damaging the underlying surface.

A handheld laser cleaning machine is often used for flexibility in industrial environments. Its precision and non-contact process make it suitable for delicate materials like aluminum, stainless steel, and even historical artifacts.

Dry Ice Blasting

Dry ice blasting propels solid CO₂ pellets at high speed onto the surface. Upon impact, the pellets create micro-explosions due to rapid sublimation (changing from solid to gas). This thermal shock, combined with kinetic energy, lifts away dirt, oil, and coatings.

It’s commonly used in industries where residue-free cleaning is critical, such as food processing or electronics. The CO₂ evaporates, leaving no secondary waste.

Sandblasting

Sandblasting is the most traditional method, using abrasive particles (sand, grit, or steel shot) blasted at high velocity to scrape away contaminants. It is extremely effective for removing thick rust, corrosion, or paint layers.

However, the process is aggressive, can erode base materials, and generates significant dust and waste. It is often reserved for heavy-duty industrial and construction applications.

Key Comparisons

Cleaning Effectiveness

Laser Cleaning: Extremely precise, ideal for rust, oxides, thin paint, and delicate surfaces. Great for restoring metals without abrasion.

Dry Ice Blasting: Effective against grease, oil, and softer coatings. Works well for equipment that can’t tolerate moisture or secondary residue.

Sandblasting: The most aggressive, suitable for thick coatings, heavy rust, or concrete surfaces.

Surface Impact

Laser Cleaning: Minimal to no damage. The beam targets only the contaminant layer.

Dry Ice Blasting: Gentle, non-abrasive, and preserves the integrity of the base material.

Sandblasting: Highly abrasive; may damage soft materials or fine details.

Environmental Impact

Laser Cleaning: Eco-friendly—no chemicals or blasting media, only dust particles that can be vacuumed.

Dry Ice Blasting: Leaves no secondary waste; CO₂ sublimates. Requires a reliable supply of pellets.

Sandblasting: Produces dust, waste media, and potential health hazards. Disposal is costly.

Cost and Equipment

Laser Cleaning: Higher upfront cost for a laser cleaning machine, but very low operating costs, no consumables, and long-term savings.

Dry Ice Blasting: Moderate equipment cost, but recurring expense for dry ice pellets and storage.

Sandblasting: Lower initial equipment cost, but continuous costs for abrasive media, cleanup, and waste disposal.

Safety Considerations

Laser Cleaning: Operators must wear protective glasses and follow safety protocols for high-powered lasers.

Dry Ice Blasting: Generally safe, but requires proper ventilation to prevent CO₂ buildup.

Sandblasting: High dust levels, noise, and abrasiveness make it hazardous without extensive protective gear.

Ideal Applications of Each Method

Laser Cleaning

Aerospace and automotive industries for rust and coating removal.

Precision manufacturing, where delicate parts must be cleaned without abrasion.

Cultural heritage restoration of monuments, sculptures, and artifacts.

Maintenance of tools, molds, and machinery.

A handheld laser cleaning machine offers portability for field operations, making it especially useful in large or complex environments.

Dry Ice Blasting

Food and beverage industry for cleaning processing equipment without chemicals.

Electronics industry, where sensitive components cannot be exposed to moisture.

Removing oil, grease, and dirt from machinery.

Sandblasting

Construction and shipbuilding for cleaning concrete, steel, and large metal surfaces.

Heavy-duty rust and paint removal on pipelines, tanks, and bridges.

Preparing surfaces for new coatings in industrial environments.

Pros and Cons Summary Table

| Method | Advantages | Disadvantages | Best Applications |

| Laser Cleaning | Precise, eco-friendly, no consumables, safe for delicate materials | High upfront cost, requires trained operators | Aerospace, automotive, heritage restoration, precision parts |

| Dry Ice Blasting | No residue, safe for sensitive equipment, moderate aggressiveness | Requires dry ice supply, less effective for heavy rust | Food processing, electronics, machinery cleaning |

| Sandblasting | Low initial equipment cost, very aggressive cleaning | Abrasive, high waste, environmental concerns | Construction, shipbuilding, pipelines, heavy rust removal |

Future Trends in Surface Cleaning

The demand for eco-friendly and efficient cleaning technologies is reshaping the industry. Regulatory pressures and sustainability goals are pushing companies away from traditional abrasive methods like sandblasting and toward greener options.

Laser cleaning machines are gaining popularity due to their precision, automation potential, and low environmental impact. Many industries are investing in automated or robotic laser cleaning systems for consistent results.

Dry ice blasting continues to grow in sectors where contamination control is critical, such as pharmaceuticals and food production.

Sandblasting remains in use for heavy-duty projects, but stricter safety and environmental regulations may limit its scope in the future.

Conclusion

Choosing between laser cleaning, dry ice blasting, and sandblasting depends on the application:

- Laser cleaning is the best choice for precision, eco-friendliness, and long-term savings.

- Dry ice blasting is ideal for residue-free cleaning in sensitive industries.

- Sandblasting is still the go-to method for aggressive surface preparation in heavy industries.

As technology advances, more businesses are turning to laser cleaning machines for efficiency, safety, and sustainability. For companies seeking reliable solutions, STRION Laser is a trusted laser cleaning machine manufacturer, offering cutting-edge handheld laser cleaning machines and industrial-grade systems that deliver superior performance for a wide range of applications.