How to Reduce Welding Spatter with Laser Welding

Welding spatter—small droplets of molten metal expelled during welding—is a common challenge in metal fabrication. Excessive spatter not only affects the appearance of finished parts and increases post-weld cleaning time, but can also damage surrounding components and lead to inconsistent weld quality. For manufacturers using laser welding, controlling spatter is essential to improving efficiency, reducing costs, and maintaining stable production standards.

As a professional brand with independent R&D in laser welding technology, STRION LASER has addressed this issue through optimized system design in its MASTER X Series and LITE S Series handheld laser welders. Based on real production feedback and technical expertise, this article explains the main causes of laser welding spatter and outlines practical, proven methods to reduce it—helping manufacturers achieve cleaner welds and more reliable results.

Why Does Spatter Occur in Laser Welding?

To effectively reduce spatter, it is essential to understand its root causes. In laser welding, spatter is mainly caused by the following factors, with improper parameter settings being the most common.

1. Mismatched Welding Parameters

Laser welding parameters—including laser power, welding speed, defocus distance, and wire feeding speed—must be precisely matched to the material type and thickness. When these parameters are not properly balanced, the molten pool becomes unstable, leading to spatter.

- Excessive power or overly slow welding speed can overheat the molten pool, causing violent metal evaporation and ejection.

- Insufficient wire feeding speed prevents the molten pool from being filled in time, while excessive wire feeding speed results in incomplete wire melting—both conditions increase the risk of spatter.

- Incorrect defocus distance reduces energy density at the weld zone, disrupting molten pool stability and making spatter more likely.

2. Poor Workpiece Preparation

Improper workpiece preparation has a direct impact on molten pool stability and is a common cause of welding spatter.

- Surface contaminants such as oil, grease, rust, oxide layers, or paint burn rapidly during welding, releasing gas into the molten pool. This gas expansion disrupts the pool and causes metal droplets to eject as spatter.

- Excessive joint gaps—typically greater than 0.3 mm—make it difficult to control molten metal flow, leading to unstable weld formation and increased spatter.

Ensuring clean surfaces and proper fit-up before welding is essential for achieving a stable molten pool and clean weld appearance.

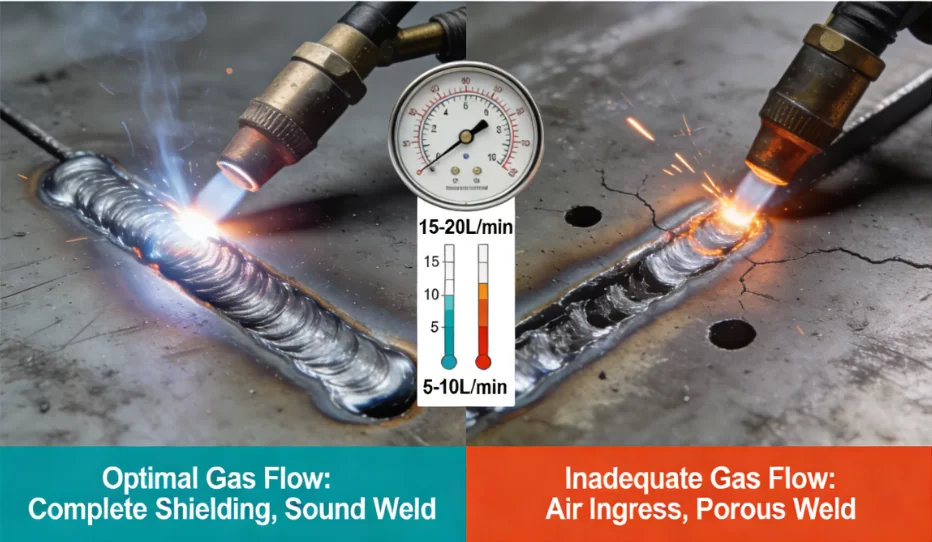

3. Insufficient Gas Shielding

Proper shielding gas, usually argon, is essential for stabilizing the weld pool and preventing oxidation. The following issues can cause spatter:

- Gas flow that is too low, failing to fully cover the weld pool and allowing air to react with the molten metal.

- Torch positioned too far from the workpiece or at an incorrect angle, resulting in uneven protection.

- Impure shielding gas containing moisture or contaminants, which can create bubbles in the weld pool.

5 Practical Methods to Reduce Laser Welding Spatter

Combining STRION LASER’s product advantages and industry best practices, the following methods effectively minimize spatter:

1. Optimize Welding Parameters with Intelligent Process Packages

Matching parameters is the foundation for reducing spatter. STRION LASER equipment simplifies this process through intelligent design:

- Use Built-in Process Packages: All MASTER X and LITE S series machines come with over 20 pre-calibrated process packages, suitable for common materials such as aluminum, stainless steel, and carbon steel, across different thicknesses. For example, when welding 3 mm stainless steel with the LITE S30 (900 W), optimized settings are: 800 W power, 120 cm/min welding speed, and a +2 mm defocus distance—parameters designed to minimize spatter effectively.

- Fine-tune Parameters Gradually: If spatter occurs, reduce power by 5–10% or increase speed by 10–15%, avoiding large adjustments. For highly reflective materials like aluminum, use the MASTER X series with high-beam-quality lasers and a slightly positive defocus distance to stabilize the weld pool.

- Match Wire Feed Speed: For 1.2 mm welding wire, a feed speed of 60–80 cm/min combined with 1500 W power (MASTER X50) ensures complete melting without generating spatter.

2. Standardize Workpiece Preparation

Clean and properly assembled workpieces help prevent spatter caused by contaminants or gaps:

- Thoroughly Clean Surfaces: Remove oils and grease using acetone or ethanol, and eliminate rust or oxidation with a wire brush or sandblasting. Ensure the workpiece surface is dry and bright before welding.

- Control Assembly Gaps: Maintain gaps between parts ≤0.3 mm. Use clamps to secure components for precise alignment, preventing molten metal from escaping and generating spatter.

- Preheat When Necessary: For high-carbon steel or workpieces ≥5 mm thick, preheat to 100–200 °C to reduce thermal stress and stabilize the weld pool.

3. Improve Gas Shielding

Proper gas shielding prevents oxidation and stabilizes the weld pool:

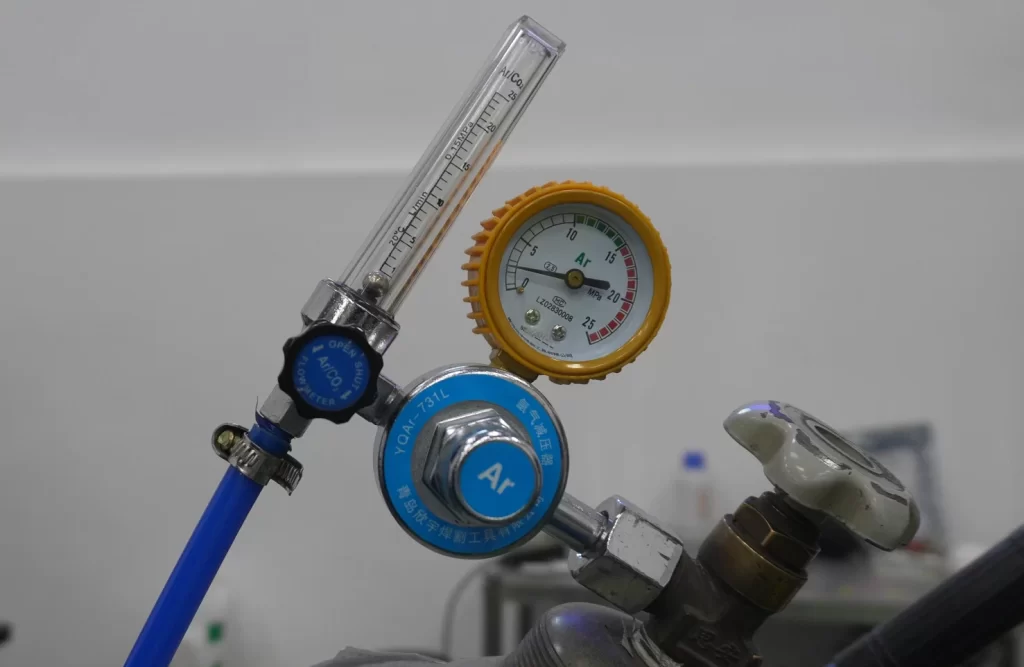

- Use High-Purity Shielding Gas: Select argon with ≥99.99% purity to avoid spatter caused by moisture or impurities.

- Adjust Gas Flow and Nozzle Position: For handheld welding, set the gas flow to 15–25 L/min. Use STRION K-series ergonomic torches to maintain a 3–5 mm distance between the nozzle and the workpiece, ensuring even coverage of the weld area.

- Regularly Inspect the Gas System: Check hoses for leaks and nozzles for blockages. Replace worn nozzles promptly to maintain a stable gas flow.

4. Leverage Equipment Design to Reduce Spatter

STRION LASER welding equipment features anti-spatter designs that minimize reliance on operator skill:

- Anti-Spatter Torch: The independently developed K-series torch, weighing only 390 g, features an air-knife cleaning function and anti-spatter design. It blows away spatter, keeps optical components clean, and prevents debris from adhering to lenses, ensuring consistent laser output.

- Stable Laser Output: STRION’s proprietary laser source has an annual power decay of less than 1% and long-term fluctuation below 1%, providing stable energy delivery and preventing weld pool overheating or instability.

- Dual-Circuit Cooling System: The dual-circuit refrigerant cooling system maintains device temperatures between -30 °C and 60 °C, preventing power fluctuations caused by overheating that could lead to spatter.

5. Perform Regular Equipment Maintenance

Well-maintained equipment ensures stable performance and minimizes spatter:

- Clean Optical Components Weekly: Wipe protective windows and focusing lenses with a lint-free cloth moistened with isopropyl alcohol to remove dust and spatter residue. Avoid scratching surfaces to maintain optimal energy transmission.

- Maintain the Wire Feeder: For STRION’s STR-WFS-A (single-wire) or STR-WFD-A (dual-wire) feeders, clean the drive rollers monthly to ensure smooth and consistent wire feed. Check for kinks or blockages in the wire guide tube.

- Calibrate Laser Power Quarterly: Use a power meter to verify output. If decay exceeds 5%, contact STRION technical support for calibration to ensure stable and consistent energy delivery.

Case Study: How a Hardware Factory Reduced Spatter by 90%

A hardware factory in Guangdong, producing stainless steel kitchenware, faced severe spatter issues with traditional welding equipment, requiring three workers daily to clean weld seams. After switching to STRION LASER’s STR-HW550(1500 W) laser welding system, the factory achieved remarkable results:

- Pre-calibrated Process Packages: Using the 2 mm stainless steel welding package immediately reduced spatter significantly.

- K-Series Torch Air-Knife Function: Effectively prevented spatter from sticking to lenses, maintaining stable equipment performance.

- Standardized Workpiece Cleaning: A routine of acetone wiping and wire brushing eliminated spatter caused by oil and oxidation layers.

After one month of operation, spatter decreased by 90%, the number of workers required for post-weld cleaning dropped by two, monthly production efficiency increased by 30%, and weld seams were smoother, reducing polishing costs.

Conclusion: Clean Welding Starts with the Right Equipment and Practices

Welding spatter is not inevitable. By optimizing parameters, properly preparing workpieces, ensuring adequate gas shielding, and using reliable equipment, spatter can be effectively controlled. STRION LASER’s MASTER X and LITE S series machines integrate intelligent process packages, anti-spatter torch designs, and stable laser output to help factories minimize spatter without relying on highly skilled operators.

From small workshops to large industrial facilities, these solutions not only reduce post-weld processing costs and improve production efficiency but also enhance product quality and consistency. By combining STRION LASER’s equipment advantages with standardized operational practices, you can achieve clean, efficient welding and gain a competitive edge in manufacturing.

If you are struggling with welding spatter or need personalized parameter recommendations for specific workpieces, visit the STRION LASER official website www.strlaser-en.com or call +86-28-85812068. Our technical team provides one-on-one support to help you optimize your welding process.