How to Choose the Right Handheld Laser Welding Machine for Your Factory

In today’s era of manufacturing upgrades, selecting a handheld laser welding machine is no longer a simple matter of choosing higher power. The right solution must match your factory’s production scale, workpiece characteristics, and long-term development plans. An incorrect choice can lead to insufficient capacity, wasted investment, or reduced production efficiency.

As a professional brand with in-house R&D and manufacturing capabilities, STRION LASER offers three main product lines—LITE S Series, MASTER X Series, and HW Series—designed to cover a wide range of industrial applications. By combining real production scenarios with clear product positioning, this article outlines a practical selection framework to help you identify the most cost-effective handheld laser welding solution for your factory.

Step 1: Define Your Core Requirements — Start with the Workpiece and Production Scale

Choosing the right handheld laser welding machine starts with a clear understanding of your factory’s real production needs. Before comparing models or power levels, two factors should always come first: the workpiece specifications and the typical production scope.

1. Workpiece Specifications: Material and Thickness

Different materials and thicknesses place very specific demands on laser power and welding performance. STRION LASER’s product lines are precisely configured to meet these requirements:

Thin sheet applications (≤ 4 mm)

For aluminum, stainless steel, carbon steel, or galvanized sheet up to 4 mm thick, the LITE S Series is a practical and cost-effective choice.

- LITE S30 (900W) is suitable for welding up to 3 mm aluminum, 3 mm stainless steel, and 2 mm galvanized steel.

- LITE S40 (1200W) extends the capacity to 4 mm aluminum and carbon steel, making it ideal for light fabrication and small workshops.

Medium to thick plate applications (5–10 mm)

For thicker materials, the MASTER X Series delivers the required penetration and stability.

- MASTER X50 (1500W) supports welding up to 5 mm aluminum and carbon steel.

- MASTER X60 (2000W) handles 6 mm aluminum and stainless steel.

- The flagship MASTER X80 (3000W) enables single-pass welding of up to 10 mm carbon steel and 8 mm stainless steel, meeting the needs of heavy-duty industrial applications.

Multi-material compatibility

All STRION LASER handheld welding machines support aluminum, stainless steel, carbon steel, galvanized steel, and even copper. The in-house developed laser source is optimized for high-reflective materials, minimizing energy loss and ensuring stable welding performance—especially when working with aluminum.

Step 2: Match Equipment Performance with Your Factory Environment

Once your production requirements are clear, the next step is ensuring the equipment fits your factory’s power conditions, space limitations, and operating environment. A mismatch here often leads to installation issues, unstable operation, or unnecessary upgrades later.

1. Power Supply and Space Requirements

Power compatibility

The LITE S Series (S30 / S40) operates on a 220V single-phase power supply, making it ideal for small workshops or facilities without access to industrial three-phase electricity. No additional power conversion is required.

The MASTER X Series (X50 / X60 / X80) requires a 380V three-phase power supply, which is standard in medium and large factories with industrial electrical infrastructure.

Space adaptability

The LITE S Series features a compact footprint (748 × 412 × 624 mm) and weighs only 39 kg, making it easy to deploy in space-constrained workshops or flexible workstations.

The MASTER X Series, while heavier (50–85 kg depending on model), is equipped with integrated armored cables (5 m or 10 m), allowing operators to move freely across large production areas without relocating the main unit.

2. Environmental Adaptability

Factories with harsh conditions—such as high dust levels, temperature fluctuations, or humidity—require equipment designed for stable long-term operation.

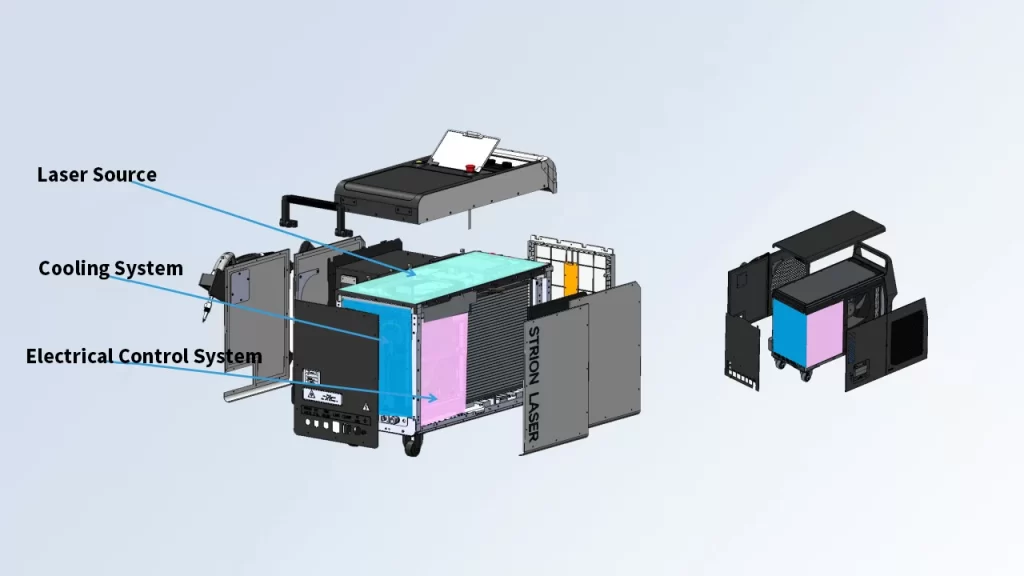

- All STRION LASER handheld welding machines use a dual-circuit refrigerant direct-cooling system, ensuring reliable operation in temperatures from –30°C to 60°C and humidity levels up to 90%.

- The MASTER X Series features IP53 protection, along with shock-resistant construction and strong shielding against electromagnetic interference and metal dust, making it well suited for heavy industrial environments.

- The LITE S Series offers IP5X dust protection and IPX3 water resistance, fully meeting the demands of typical small and mid-sized workshops.

Step 3: Evaluate Operating Costs and Long-Term Ownership Costs

The true cost of a welding machine goes far beyond the initial purchase price. Ease of operation, labor requirements, energy consumption, and maintenance costs all have a direct impact on long-term productivity and return on investment.

1. Operating Threshold and Labor Costs

Low skill requirement

All STRION LASER handheld welding machines are equipped with over 20 built-in welding process programs. Operators simply select the program based on material type and thickness, and the system automatically applies the optimal parameters—including laser power, welding speed, and wire feed rate. This greatly reduces reliance on highly skilled welders and helps factories address ongoing labor shortages.

Ergonomic design for efficiency

The in-house developed K Series welding torch, weighing only 390 g, significantly reduces operator fatigue during long shifts. On the LITE S Series, the quick-release wire feeder and clearly labeled interfaces allow fast wire loading and setup, improving workflow efficiency and minimizing downtime between jobs.

2. Energy Consumption and Maintenance Costs

Energy efficiency

Compared with traditional welding methods, advanced fiber laser technology can reduce energy consumption by up to 60%. For example, the LITE S30 has a rated input power of only 3000 W, helping small and medium-sized workshops keep electricity costs under control.

Low maintenance requirements

The modular design simplifies routine maintenance. Protective windows and focusing lenses can be replaced quickly without specialized tools, reducing service time and labor costs. The dual-circuit cooling system extends component lifespan, with an annual laser power attenuation rate of less than 1%, ensuring stable performance over years of operation.

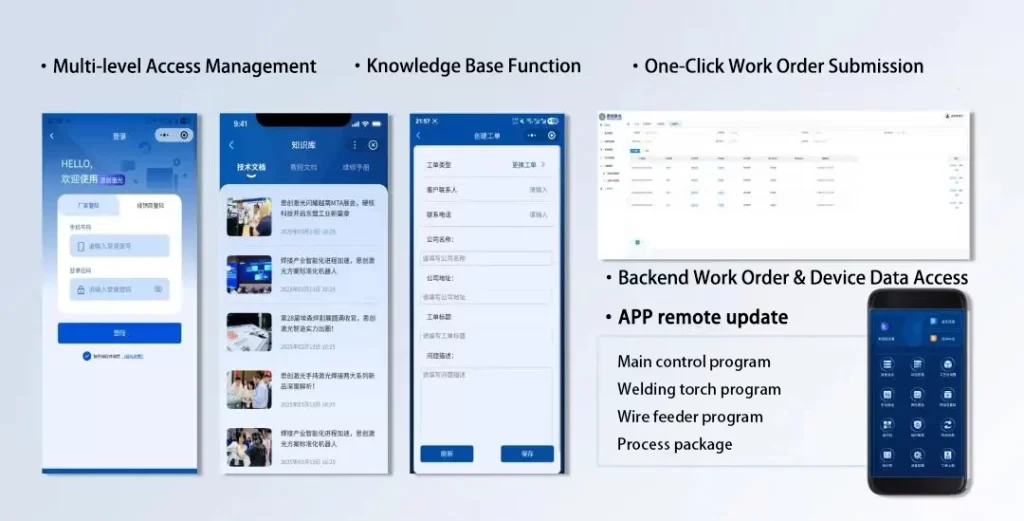

Warranty and service support

STRION LASER provides a 2-year comprehensive warranty and 24/7 technical support. With local service centers in multiple regions, customers benefit from on-site training and fast response times. For bulk purchases, free maintenance spare parts are also available, helping to minimize downtime and protect production continuity.

Step 4: Plan for Future Expansion and Business Growth

When selecting a handheld laser welding machine, it is important to look beyond current production needs and leave room for future expansion as your business grows.

1. Functional Scalability

Multi-process capability

The MASTER X Series supports welding, laser cleaning, cutting, and cladding through multiple digital and I/O interfaces. A single machine can handle both thick-plate welding and surface cleaning for rust or oxide removal, enabling true multi-function use and reducing the need for additional equipment investment.

Automation readiness

All MASTER X models support 5G + AI connectivity and multiple industrial communication protocols, allowing seamless integration with robotic systems and automated production lines. Small workshops can start with manual handheld welding and gradually upgrade to automation as production volume increases—without replacing the core equipment.

2. Customization Options

For factories with specific industry or branding requirements, STRION LASER offers customization for bulk orders, including logo branding, machine color, model configuration, and language options. This ensures the equipment aligns with your factory’s operational habits and brand identity while maintaining full technical performance.

Step 5: Match Product Series to Factory Scenarios—Quick Selection Guide

To simplify the decision-making process, here’s a direct matching table for common factory scenarios and STRION LASER products:

| Factory Type | Core Needs | Recommended Series/Model | Key Advantages |

| Small workshop (hardware, daily necessities) | Thin-sheet welding (≤3mm), flexible movement, low skill threshold | LITE S30 (900W) | 220V power, 39kg lightweight, no skilled operators needed |

| Medium-sized factory (sheet metal processing, auto parts) | 3-5mm workpieces, stable batch production, cost-effectiveness | LITE S40 (1200W) / HW Series | Balanced performance, 4mm processing capacity, low energy consumption |

| Professional processing factory (thick-plate components) | 5-8mm thick plates, high efficiency, industrial-grade stability | MASTER X50 (1500W) / X60 (2000W) | Deep penetration, continuous operation, dust/waterproof design |

| Heavy industry enterprise (large machinery, steel structures) | ≥8mm thick plates, multi-process integration, automation | MASTER X80 (3000W) | 10mm carbon steel welding, welding/cleaning/cutting integration |

Conclusion: Choose the Right Equipment to Improve Factory Efficiency

Selecting a handheld laser welding machine is a strategic decision that requires careful evaluation of workpiece materials, production volume, site conditions, and long-term growth plans. STRION LASER offers three dedicated product lines—LITE S Series for flexible thin-sheet welding, HW Series for balanced reliability, and MASTER X Series for industrial-grade power—designed to meet the real needs of factories at different stages of development.

From the low learning curve of the LITE S Series to the multi-process and automation-ready capabilities of the MASTER X Series, every STRION LASER machine integrates core technologies developed in-house, including high-quality laser sources, stable dual-circuit cooling systems, and user-oriented intelligent design. This ensures consistent performance, controlled operating costs, and improved productivity across a wide range of manufacturing environments.

If you require model recommendations based on specific workpieces or production lines, visit the STRION LASER official website at www.strlaser-en.com or contact our technical team at +86-28-85812068. We provide one-to-one technical consultation and on-site demonstrations to help you select the most suitable solution for your factory.