Among the wide range of laser applications available in the market, additive manufacturing applications have almost the most stringent standards for laser source indexes. Due to the specificity of the manufacturing scenarios, the stability and consistency of the laser source need to have an extraordinary performance in order to support the requirements for high precision in additive manufacturing processing.

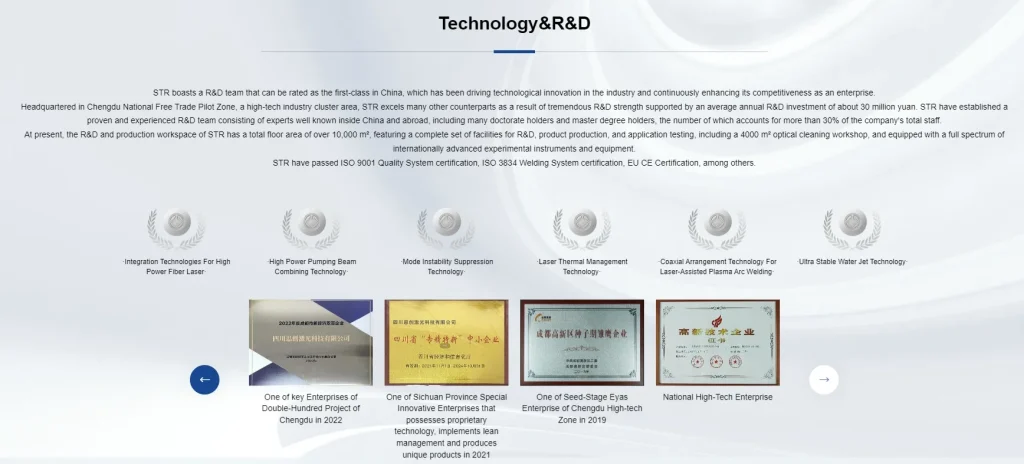

On the road of R&D and manufacturing of fiber lasers for additive manufacturing, SICHUAN STRONGEST LASER TECHNOLOGY CO., LTD (STR) deeply understands that “A journey of a thousand miles begins with a single step”, and that even the longest and the hardest road, step by step, we will reach the other side of the shore.

Continuing the hard-core technology manufacturing gene, continuous breakthrough innovation

At the initial stage of the project of STR additive manufacturing special fibre laser, similar products were scarce in China, and there were only a few foreign products, which almost monopolized the market demand in China.STR based on years of research and development of laser sources, production experience, reference to the products of developed countries in Europe and the United States, its technology and applications as a base, to lead the international development of advanced science and technology of additive manufacturing as the goal, for the country to put forward the “advancement of scientific and technological self-reliance and self-reliance, and strive to break through the bottleneck problems”, and “Promote the localisation of key technologies and key components”, focus on layout in advance, improve the quality and quantity of the development of supporting technologies in line with the national strategy, and it only took more than one year to realise the industrial landing of special fibre laser products for additive manufacturing, always standing in the front line of the process of actively promoting the localisation of the products and cooperating with a number of well-known domestic equipment manufacturers to carry out Product verification.

Over the past few years, STR has actively collected feedback from the cooperating manufacturers, and in the process of improving the product indexes together, travelled to more than 50 cities in the world, visited 30 domestic and foreign manufacturers, and purchased a total of more than 20 products, constantly learning from the advanced technology and development abroad, researching into the influencing factors on the effect of the finished products of SLM (laser fusion)/SLS (laser sintering) printing in different scenarios and under different applications, and importing them into the research and development indexes of the laser source, and constantly refining and upgrading them, and the STR’s special-purpose optical fibre lasers for Additive Manufacturing have already completed three rounds of iterations.

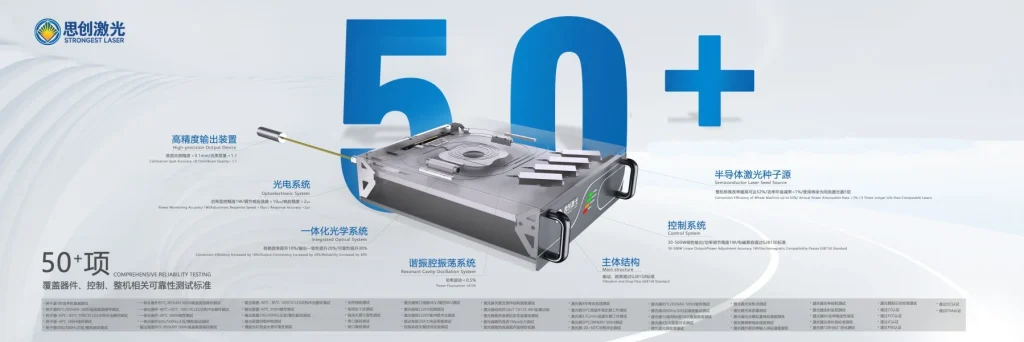

In order to meet the standards of additive manufacturing applications and to promote the localisation of key components, STR has cooperated with the industry’s leading enterprises, and after nearly four years of multiple rounds of validation and testing, improved and upgraded the performance of the previous generation of lasers, and launched the third-generation, newly upgraded AM-I 2.0 special fibre laser for additive manufacturing in 2023.

One step at a time, with ingenuity to the original heart

In the process of upgrading the third-generation AM-I 2.0 series products, STR deeply understands that, as a manufacturer of core components for additive manufacturing equipment, the depth of understanding of the equipment manufacturer’s testing conditions, testing methods, and usage experience largely determines whether or not the product can be improved more accurately.

Taking application scenarios as the premise and improving product performance as the goal, STR strengthens the resource intercommunication with various cooperative manufacturers, arranges scientific researchers to go into the front line of R&D and manufacturing of additive manufacturing equipments, and has an in-depth understanding of the testing conditions and testing methods of equipment manufacturers.

In response to the inability to repeatedly verify the parameters at the manufacturer’s site within a short period of time, and in order to carry out actual tests with greater intensity, STRONGEST LASER invested a large amount of funds to replicate and build the existing test platforms of various equipment manufacturers, and to restore the most realistic test conditions and test methods at the site. Finally, on the AM-I 2.0 products, the heat dissipation structure and manufacturing process were optimised to enhance the factory consistency, usage stability and environmental adaptability to a new height.

Power instability <0.3%

Achieve the domestic head level, effectively reduce the defective rate of metal 3D printing production, improve the production efficiency of manufacturers and users, reduce production costs.

24% increase in laser power margin

Reduced power degradation by more than 5 times

Deeply explore the potential of the product, significantly extend the life cycle of the laser light source products, and show better power stability, to ensure that the equipment printing effect.

Electromagnetic compatibility through the GB/T17626 series of national standards

Transport vibration/drip/salt spray test passed GJB150 standard

Successfully passed the test of GJB and other series of national standards, with high environmental adaptability to ensure the reliability of continuous use during the product life cycle, effectively reducing the failure rate in print production.

At present, the laser has passed a number of international certifications, such as EU CE, U.S. FCC, U.S. FDA, Canada IC, Japan PSE and so on.

STRONGEST LASER has always insisted on keeping its feet on the ground and striving for excellence, not stopping at the day-to-day refinement of core components and optical technology. The third-generation AM-I 2.0 series products are not only satisfied with meeting the entry requirements of additive manufacturing applications, but also promote the localisation of key components from the perspective of customer needs and application scenarios, support the national strategy with hard-core laser technology, and contribute to the power of STRONGEST LASER for China’s high-end manufacturing.