Strion Laser, a leading innovator in handheld laser welding technology, continues to empower fabricators with advanced solutions tailored to real-world challenges. Recently, users raised two recurring questions in their welding applications: how to achieve smooth arc pit control during weld termination, and how to efficiently weld thick stainless steel plates with consistent penetration and quality.

Strion Laser has responded with a comprehensive process demonstration, sharing both detailed welding parameters and practical results from field applications.

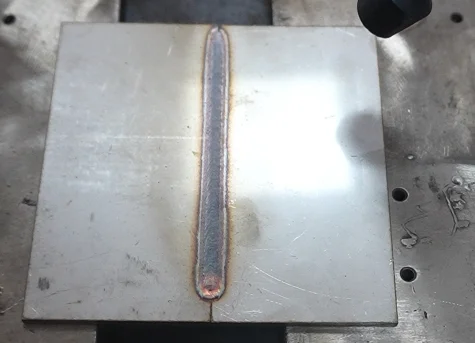

Challenge 1: Perfect Arc Termination – Smoother, Stronger, More Aesthetic Welds

Solution: MASTER X60 Handheld Laser Welder

Core Issue: At the weld end, sudden energy drop often causes crater-like arc pits, reducing strength and appearance.

Strion Solution:

a.Smart Wire Control: Wire feed delay of 200 ms, with 10 mm backfeed + 10 mm refill length, allowing clean wire breaks without sticking.

b.Energy Ramping: Power ramp-up of 400 ms and ramp-down of 500 ms for smooth energy transition, avoiding rapid cooling and shrinkage.

c.Stable Parameters: Power 55%, frequency 20 Hz, wobble width 3.0 mm, welding speed 60 cm/min, delivering dense and uniform welds.

Result: Weld seam transitions smoothly at the end, effectively minimizing arc pits while improving both mechanical strength and surface aesthetics.

How to reduce crater defects: https://www.youtube.com/shorts/0MTdxvcugW0

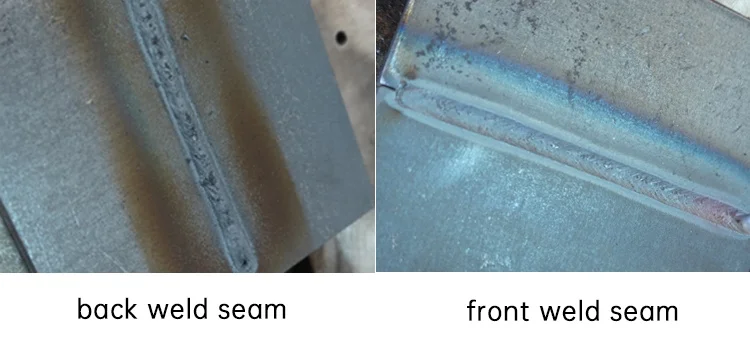

Challenge 2: High-Efficiency Welding of 8 mm Stainless Steel Plates

Solution: MASTER X80 Handheld Laser Welder with Dual-Wire Feed

Core Issue: Thick plate welding requires deep penetration with stable molten pool dynamics and strong back-side formation.

Strion Solution:

a.High Power Penetration: 100% laser power enables single-pass penetration of 8 mm stainless steel.

b.Dual-Wire Filling: Dual 1.6 mm wire, feeding at 30 cm/min, increasing filler deposition for stronger joints.

c.Uniform Heat Input: 20 Hz frequency with 5.0 mm wide oscillation ensures balanced thermal distribution and robust weld width.

d.Back-Side Formation: Consistent back-bead appearance without the need for secondary welding.

Result: Single-side welding, double-side formation – significantly boosting efficiency while ensuring deep penetration and strong fusion.

Why Choose Strion Laser Handheld Welding Technology?

Precision & Efficiency: Advanced control algorithms with ultra-fast response guarantee accurate parameter execution and stable welding results.

Reliability & Durability: Core components are independently developed, ensuring long-term stable output even under high workloads.

Smart & User-Friendly: Intuitive interface with quick parameter tuning, one-click storage, and easy recall – helping welders adapt faster and maximize productivity.

About Strion Laser

Strion Laser is committed to advancing laser welding solutions that combine precision, efficiency, and reliability. From arc pit elimination to thick plate welding, our handheld laser welding machines deliver unmatched performance across industries, including stainless steel fabrication, automotive parts, sheet metal processing, and heavy equipment manufacturing.

With a relentless focus on user needs, Strion Laser continues to provide the technology, service, and expertise that manufacturers trust to achieve stronger welds, higher efficiency, and superior product quality.