Handheld Laser Welding vs. Arc and TIG Welding:Process Differences and Real Applications

In the metalworking industry, the choice of welding process is rarely driven by trends, but rather by its stability, efficiency, and long-term reliability.

For decades, electric arc welding (EAW) and TIG welding have been the standard choices in workshops. However, in recent years, handheld laser welding has begun to appear in more production environments, sparking not hype, but practical questions: In what areas does it perform better? In what areas does it perform worse? And what changes does it bring to daily operations?

This article compares handheld laser welding with traditional EAW and TIG welding from a process and application perspective, focusing on the truly important practical differences in production.

I. The Evolution of Welding Technology: From “Rough” Processing to Precision Control

Welding has always been a core process in manufacturing, and its technical evolution has consistently centered on three fundamental demands: efficiency, quality, and flexibility. Traditional welding methods—represented by arc welding and TIG welding—have long dominated applications such as thick-plate fabrication and on-site repair, largely due to their low equipment cost and tolerance to harsh environments.

However, as precision manufacturing and high-volume production continue to advance, the inherent limitations of traditional welding have become increasingly evident.

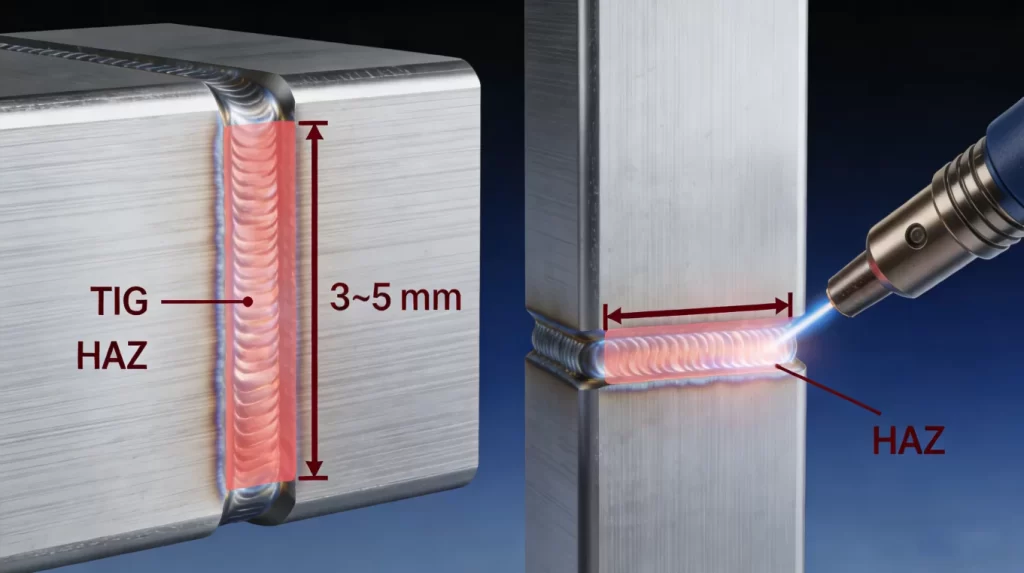

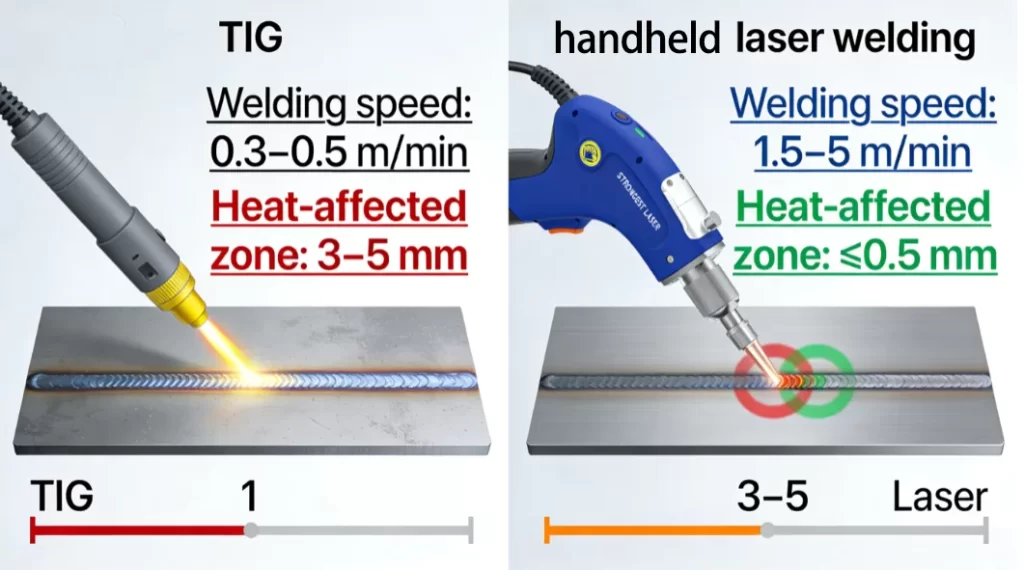

When welding 3 mm stainless steel using TIG welding, the heat-affected zone typically reaches 3–5 mm, leading to excessive thermal diffusion into the base material.

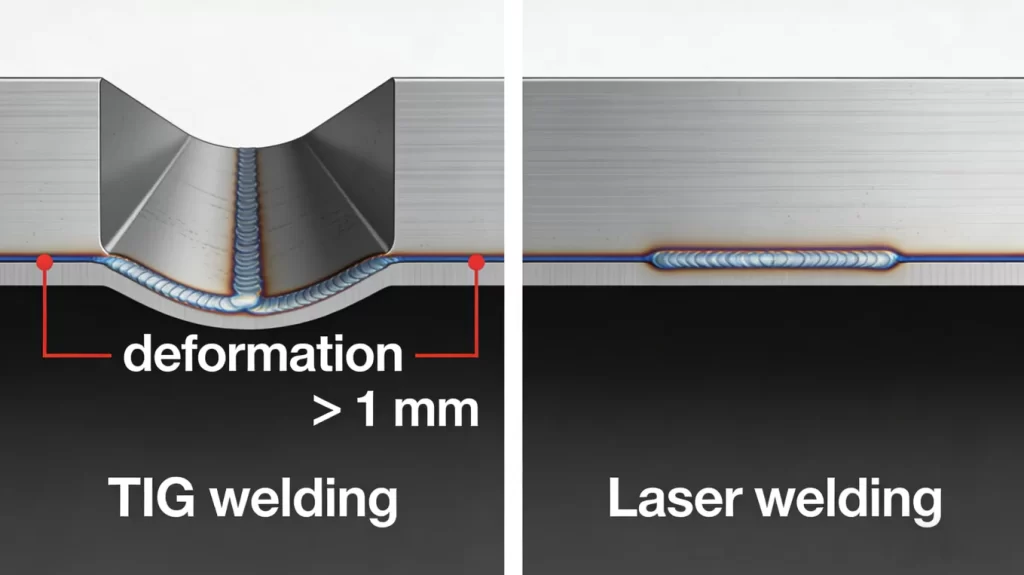

In production environments, this thermal behavior often results in post-weld deformation exceeding 1 mm, affecting dimensional accuracy and assembly consistency.

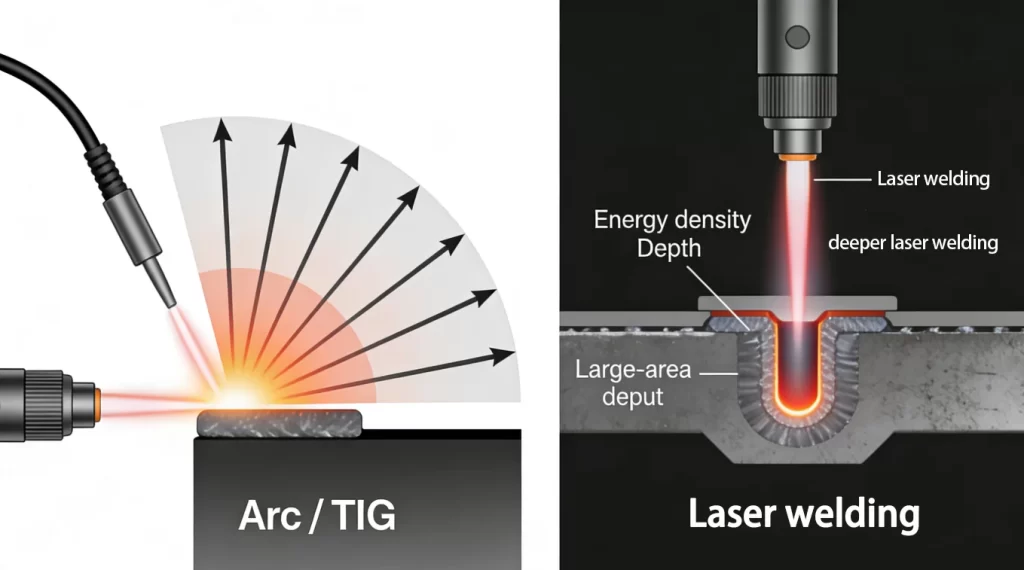

Handheld laser welding uses fiber-delivered laser beams with energy densities up to 10⁶ W/mm², forming a keyhole-type deep penetration weld and achieving over 60% energy utilization, compared with roughly 30% in conventional arc welding.

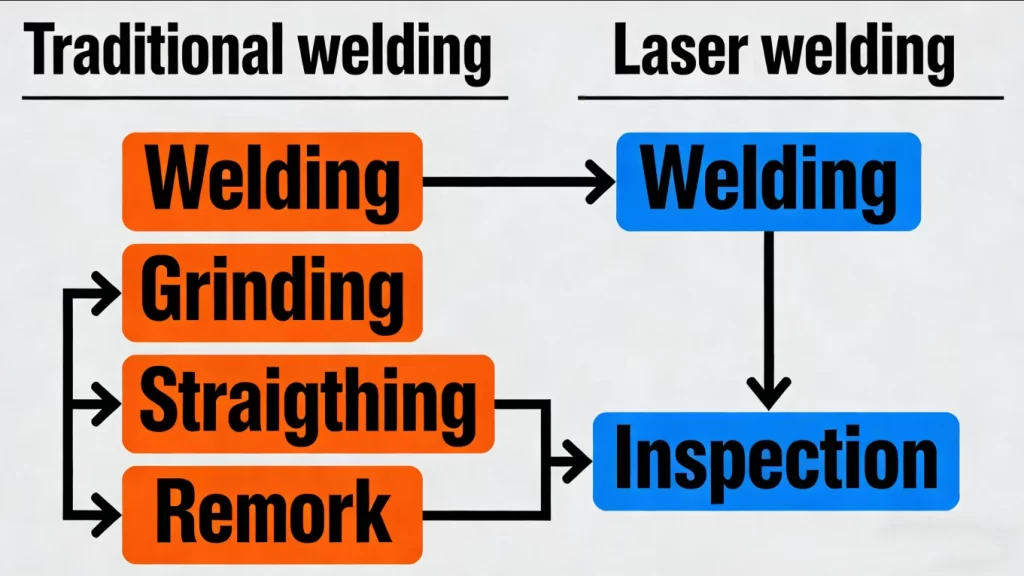

In traditional welding workflows, post-processing such as grinding and reshaping can account for more than 30% of total labor time. In contrast, laser welding produces smoother weld beads with consistent appearance, significantly reducing secondary operations and improving overall production efficiency.

II. Core Performance Comparison: Why Handheld Laser Welding Is Becoming the Preferred Choice for Precision Manufacturing

1. Efficiency and Quality: A Dual Leap in Speed and Accuracy

Handheld laser welding systems achieve welding speeds of 1.5–5 m/min, approximately three to five times faster than TIG welding. At the same time, the heat-affected zone is reduced to ≤0.5 mm, with overall deformation limited to roughly one-eighth of that caused by traditional welding.

The resulting weld seams are smooth, airtight, and visually consistent, often eliminating the need for post-weld grinding. In large-scale production environments such as home appliances and automotive components, this translates into over 40% labor cost reduction and significantly lower defect rates.

2. Process Stability and Operator Dependence

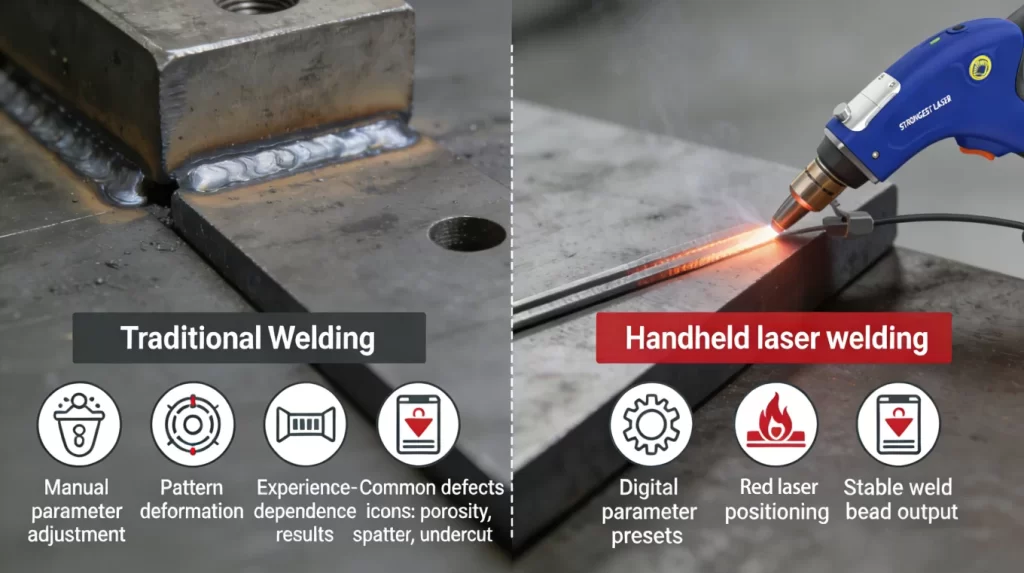

Traditional welding relies heavily on operator experience for parameter adjustment, making weld quality susceptible to defects such as porosity, slag inclusion, and burn-through—particularly when working with thin sheets.

In contrast, handheld laser welding adopts digital parameter control combined with red-laser positioning, allowing new operators to become productive after 1–3 days of training, significantly reducing dependence on highly skilled welders while improving process repeatability.

3. Material and Thickness Capability: Breaking the Traditional Limits

The perception that handheld laser welding is limited to thin sheets below 6 mm no longer holds true.

Taking the STRION LASER STR-Master X80 as an example, its 3000 W true-output laser source, combined with 20 μm fiber transmission and a dual-loop refrigerant temperature control system, enables carbon steel penetration depths of up to 10 mm, and 12 mm with optimized parameters.

In demanding applications such as 10 mm carbon steel structures for military vehicles, welding speed reaches four times that of TIG welding, while post-weld deformation remains below 0.3 mm, eliminating the need for corrective straightening.

4.Cost Structure: Balancing Initial Investment and Long-Term Return

While handheld laser welding systems require a higher initial investment ( 100,000–300,000), their long-term operating cost is significantly lower. The absence of consumables such as electrodes and tungsten rods, combined with over 30% lower energy consumption, and minimal post-processing, allows batch manufacturers to typically recover the investment within two to three years.

By contrast, traditional welding remains more suitable for low-volume production and occasional repair work, where equipment cost outweighs efficiency considerations.

| Key Metrics | Traditional Welding (TIG/Arc) | Handheld Laser Welding |

| Initial Investment | 50,000 – 200,000 | 100,000 – 300,000 |

| Consumable Requirement | High (electrodes, tungsten, grinding) | Ultra-low (only small shielding gas) |

| Energy Consumption | Standard (10–20kW) | 30%+ lower (60–70% of traditional) |

| Labor & Post-processing Cost | High (professional welders + rework) | Low (beginners operable + no rework) |

| Return on Investment (ROI) | No clear payback period | 2–3 years (mass production) |

| Primary Application | Small-batch, maintenance, emergency | Medium-to-high volume, precision parts |

III. Application Expansion: From Precision Thin Sheets to Heavy-Plate Welding Tasks

Handheld laser welding is distinguished by its exceptional flexibility. It is equally capable of micro-scale precision welding—such as electronic components and medical devices—and on-site installation of large structural assemblies.

With a welding torch weighing approximately 600g and a fiber delivery length exceeding 10 meters, handheld laser systems enable true three-dimensional welding at virtually any angle. Whether performing corner welds on kitchen and sanitary hardware or butt welding thick plates for construction machinery, the process adapts easily to complex working conditions while significantly reducing operational difficulty.

Traditional welding methods remain suitable for low-budget, small-batch scenarios such as field repairs and occasional steel structure maintenance. However, their environmental drawbacks are becoming increasingly apparent. Large amounts of welding fumes, spatter, and intense arc light not only require additional ventilation and protective equipment—raising overall costs—but also pose long-term health risks to operators. This growing emphasis on workplace safety and environmental compliance is a key factor driving the manufacturing industry’s shift toward laser welding solutions.

IV. How to Match Welding Solutions to Your Requirements

Selecting welding equipment fundamentally requires balancing four key factors: precision requirements, production scale, material thickness, and budget. Based on these, the following selection guidelines are recommended:

- High-volume, precision, low-deformation production with material thickness 0.5–12 mm:

Handheld laser welding is the optimal choice. Systems like STRION LASER that can reliably weld 10–12 mm thick plates cover both thin-sheet precision tasks and thick-plate challenges, offering superior adaptability. - Budget-limited scenarios, thick plates (≥15 mm), or unstable field power supply:

Traditional arc or TIG welding remains indispensable, providing essential functionality with lower upfront cost. - Mixed production scenarios (both thin-sheet precision and thick structural components):

A combined solution of laser welding and traditional welding balances efficiency, adaptability, and overall cost-effectiveness.

Contact STRION LASER

📞 +028-85812068

🌐 www.strlaser-en.com

📧 str@strlaser.com