Handheld Laser Welding for Stainless Steel: Parameters & Tips

Stainless steel is widely used across manufacturing, construction, and consumer goods thanks to its corrosion resistance, durability, and clean appearance. However, welding stainless steel requires precise control. Excessive heat input can easily cause deformation, uneven weld seams, or a reduction in corrosion resistance.

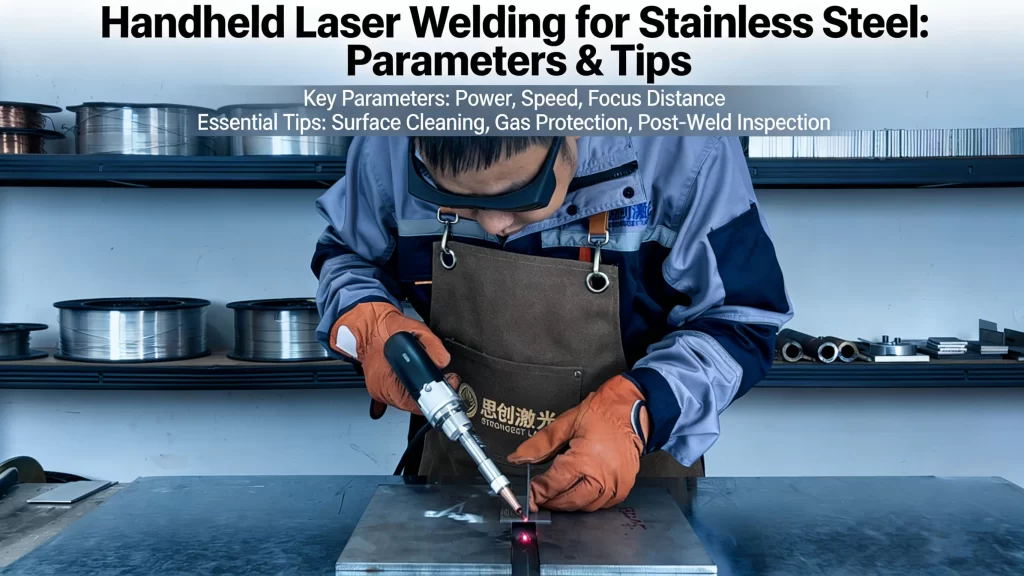

Handheld laser welding has become an ideal solution for stainless steel fabrication. With its low heat input, high efficiency, and clean welding results, it allows manufacturers to achieve strong, visually consistent welds while minimizing distortion and post-processing.

As a professional brand with independent R&D capabilities in laser welding technology, STRION LASER has specifically optimized its MASTER X Series and LITE S Series handheld laser welders for stainless steel applications. Based on both technical design advantages and real-world application experience, this article outlines key welding parameters, practical operating tips, and common troubleshooting methods to help you achieve reliable, high-quality stainless steel welds in daily production.

Key Parameters for Stainless Steel Laser Welding

Parameter matching directly determines weld quality—STRION LASER’s pre-calibrated process packages simplify this, but understanding core parameters helps fine-tune for specific needs.

1. Select Laser Power Based on Stainless Steel Thickness

Material thickness is the primary factor when choosing laser power. STRION LASER’s handheld welding systems are designed to cover all common stainless steel thickness ranges:

- Thin sheets (≤3 mm):

LITE S30 (900W) is the optimal choice. Its output is well suited for welding 1–3 mm stainless steel, delivering sufficient penetration while minimizing heat input and deformation. - Medium thickness (3–6 mm):

LITE S40 (1200W) or MASTER X50 (1500W) are recommended. LITE S40 can complete single-pass welding on 4 mm stainless steel, while MASTER X50 provides deeper penetration and more stable fusion for 5 mm workpieces. - Thick plates (6–8 mm):

MASTER X60 (2000W) or MASTER X80 (3000W) are required. In particular, the X80 enables stable, full-penetration welding on stainless steel up to 8 mm thick without the need for multiple passes.

2. Welding Speed and Defocus Distance

- Welding speed:

For thin stainless steel sheets (1–3 mm), a speed of 120–180 cm/min with the LITE S Series balances efficiency and weld quality. For thicker plates (5–8 mm), reduce the speed to 80–120 cm/min with the MASTER X Series to ensure full fusion and stable penetration. - Defocus distance:

When welding thin sheets, use a positive defocus of +1 to +3 mm to slightly enlarge the spot size, lower energy density, and prevent burn-through. For thick plates, apply a slight negative defocus of 0 to –1 mm to increase penetration depth and improve weld strength.

3. Wire Feeding Speed and Shielding Gas Settings

- Filler wire selection:

Use ER308L or ER316L stainless steel filler wire (diameter 0.8–1.6 mm) to maintain corrosion resistance and mechanical strength. - Wire feeding speed:

- 0.8–1.2 mm wire (LITE S Series): 40–80 cm/min

- 1.2–1.6 mm wire (MASTER X Series): 60–100 cm/min

Proper matching ensures complete wire melting and helps prevent spatter.

- Shielding gas:

Use 99.99% high-purity argon with a flow rate of 15–25 L/min. The STRION K-Series welding torch provides uniform gas coverage, effectively preventing oxidation and producing clean, bright weld seams.

Practical Tips for Achieving Perfect Stainless Steel Welds

1. Pre-Weld Preparation: Cleaning and Fit-Up

- Surface cleaning: Stainless steel is highly sensitive to contamination. Thoroughly clean the joint area before welding—wipe off oil and grease with acetone or ethanol, and remove oxidation layers or fingerprints using a stainless steel wire brush or light sandblasting. Any residue can cause porosity, spatter, or weak welds.

- Joint fit-up control: Keep the joint gap ≤ 0.3 mm and use fixtures or clamps to ensure proper alignment. Poor fit-up leads to uneven weld beads and unstable penetration. For thin sheets (≤ 2 mm), tight, gap-free joints are recommended to prevent burn-through.

- Avoid unnecessary preheating: Most common stainless steel grades (such as 304 and 316) do not require preheating. Only for thick plates (≥ 8 mm) is light preheating to 80–120°C recommended to reduce thermal stress and improve weld stability.

2. Welding Operation: Stability and Technique

- Grip the torch firmly:

The STRION LASER K Series welding torch (weighing only 390 g) features an ergonomic grip, reducing fatigue during long working hours. Keep the nozzle at a consistent distance of 3–5 mm from the workpiece to ensure stable gas coverage and avoid oxidation. - Maintain a steady welding path:

For butt welds, use a straight, consistent path to ensure uniform penetration. For corner joints, employ a zigzag pattern to ensure proper fusion. Avoid sudden changes in speed, as this can lead to inconsistent bead formation and weaker welds. - Leverage intelligent features:

STRION LASER handheld welders come with built-in stainless steel process programs that automatically match the optimal parameters for your materials. This makes it easy for even inexperienced operators to achieve professional-quality welds without manual adjustments—ideal for factories with less skilled personnel.

3. Post-Weld Treatment: Preserving Corrosion Resistance

- Clean the weld area:

Remove any remaining residue with a stainless steel wire brush, then wipe the joint with a clean, lint-free cloth to prevent contamination buildup. - Apply passivation when required:

For critical applications such as food processing equipment or medical devices, use a nitric-acid-based passivation treatment to restore the chromium oxide layer and enhance corrosion resistance. - Avoid unnecessary grinding:

Excessive grinding can damage the protective passive layer. Grind only when defects are present, and always re-passivate the weld afterward to maintain long-term corrosion protection.

Common Problems & Solutions for Stainless Steel Welding

| Common Problem | Root Cause | Solution |

| Porous weld seams | Contaminated surface, impure gas, or excessive speed | Clean workpiece thoroughly; use high-purity argon; reduce speed by 10-15% |

| Black/dark welds | Insufficient gas protection or improper nozzle position | Adjust gas flow to 20-25L/min; maintain 3-5mm nozzle distance |

| Burn-through (thin sheets) | Excessive power or too slow speed | Reduce power by 5-10%; increase speed by 20%; use positive defocus (+2mm) |

| Incomplete penetration (thick plates) | Insufficient power or improper defocus | Upgrade to MASTER X Series (1500W+); use slight negative defocus |

| Weld spatter | Mismatched wire feed rate or parameter imbalance | Adjust wire feed rate to match power; use STRION LASER’s anti-spatter torch design |

Why STRION LASER Excels at Stainless Steel Welding

STRION LASER’s equipment integrates technologies tailored for stainless steel’s characteristics:

- Stable laser output: Power annual attenuation <1% and long-term fluctuation <1% ensure consistent energy delivery, avoiding uneven fusion.

- Anti-spatter & gas protection: The K-series torch’s air-knife function and optimized gas flow channel prevent spatter and oxidation, delivering bright seams.

- Extreme environment adaptability: IP5X dustproof and IPX3 waterproof ratings, along with dual-circuit refrigerant direct cooling (-30~60℃ operation), ensure stable performance in diverse workshops.

- Flexible expansion: MASTER X Series supports welding, cleaning, and cutting—one machine handles stainless steel processing and post-weld cleaning, improving efficiency.

Case Study: How a Cookware Manufacturer Improved Weld Quality

A stainless steel cookware factory in Zhejiang was long troubled by the limitations of traditional welding methods—excessive spatter, darkened weld seams, and high post-weld cleaning costs. After switching to the STRION LASER LITE S30 (900W) handheld laser welder, the results were clear and measurable:

- Spatter was effectively eliminated by using the pre-calibrated process package for 3 mm stainless steel

(1000 W power, 150 cm/min welding speed, +2 mm defocus). - Bright, clean weld seams were achieved thanks to the K-Series welding torch’s optimized shielding gas design, reducing polishing work by 60%.

- Thin-sheet welding speed doubled, while the product pass rate increased from 85% to 99.5%, significantly improving overall production efficiency and consistency.

This real-world application demonstrates how properly matched laser parameters and stable gas protection can dramatically improve stainless steel welding quality while lowering labor and finishing costs.

Conclusion: Achieving High-Quality Stainless Steel Welding Starts with the Right Tools and Techniques

Consistent, high-strength stainless steel welds depend on accurate parameter matching, proper joint preparation, and reliable equipment. The STRION LASER LITE S and MASTER X Series are designed to simplify this process through pre-calibrated process programs, ergonomic handheld torches, and stable laser output—making them suitable for everything from thin consumer products to thick industrial components.

By applying the parameters and practical tips outlined above, manufacturers can produce clean, corrosion-resistant welds with higher efficiency and less post-processing. For customized recommendations based on your specific stainless steel grade and thickness, visit www.strlaser-en.com or contact STRION LASER at +86-28-85812068 for direct technical support.