Handheld Laser Welding Safety Guide: What Operators Must Know

In the era of intelligent manufacturing, handheld laser welding machines have become essential tools for Small Workshops and industrial production, thanks to their high efficiency, flexibility, and precision. As a professional brand dedicated to laser welding technology, STRION LASER places safety at the core of both product design and real-world application.

While advanced handheld laser welding technology significantly improves productivity, operators must fully understand and follow proper safety procedures to ensure personal protection and stable production. This guide combines the design advantages of STRION LASER equipment with practical operating requirements to outline key laser welding safety guidelines, helping operators build a comprehensive and professional safety awareness.

Pre-Operation Safety: Laying a Solid Foundation for Safe Welding

Pre-operation preparation is the first and most critical line of defense for safe laser welding. Even minor oversights can lead to potential safety risks. Before starting any welding task, operators must strictly follow the safety requirements below to ensure safe, stable, and efficient operation of handheld laser welding machines.

1. Equipment Inspection: Ensuring Stable Operation of Core Components

Before each operation, a comprehensive inspection of the handheld laser welding machine is mandatory. For STRION LASER MASTER X Series and LITE S Series, operators should pay special attention to the following key components:

Dual-loop direct refrigerant cooling system

Ensure there are no leaks and that the coolant level remains within the specified range. This guarantees stable operation in extreme environments from –30°C to 60°C and prevents overheating risks.Integrated armored cable and welding torch

Inspect the cable (available in 5 m or 10 m lengths) for wear, aging, or damage. Confirm that the connection between the cable and the torch is secure and free from looseness.

STRION LASER’s self-developed K Series welding torch features an anti-spatter design and air-knife structure. Check that the protective window and focusing lens are clean and undamaged. Contaminated or damaged optics must be replaced immediately to prevent laser leakage.Laser output stability

STRION LASER equipment maintains an annual power degradation rate of less than 1%, with long-term power fluctuation below 1%. Operators should perform a short test run to verify normal laser output, ensuring there is no abnormal noise or vibration.Safety interlock systems

Confirm that the emergency stop button, door interlocks, and all other safety devices are fully functional and responsive. In the event of any abnormal condition, the system must be able to immediately shut down and cut off laser output.

2. Workspace Layout: Creating a Safe Operating Environment

The workspace must comply with laser welding safety standards and be equipped with appropriate protective measures:

- Clear warning signage

The welding area should display visible warning signs such as “Laser Operating Area – No Unauthorized Entry” to clearly isolate the welding zone and prevent unauthorized personnel from entering. - Proper ventilation

Ensure the workspace is well ventilated. Install exhaust or fume extraction systems to promptly remove welding fumes and harmful gases generated during laser welding, preventing operators from inhaling hazardous substances. - Clean and fire-safe environment

Keep the work area clean and free of flammable or explosive materials such as oil, alcohol, and wood dust. For workshops processing flammable materials like aluminum alloys or galvanized sheets, appropriate firefighting equipment (e.g., dry powder fire extinguishers) must be readily available, and operators should be trained in their proper use. - Controlled environmental conditions

Maintain an ambient temperature between –30°C and 60°C, with humidity controlled within 0–90%. These conditions align with STRION LASER equipment operating requirements and help prevent equipment failure caused by extreme environmental factors.

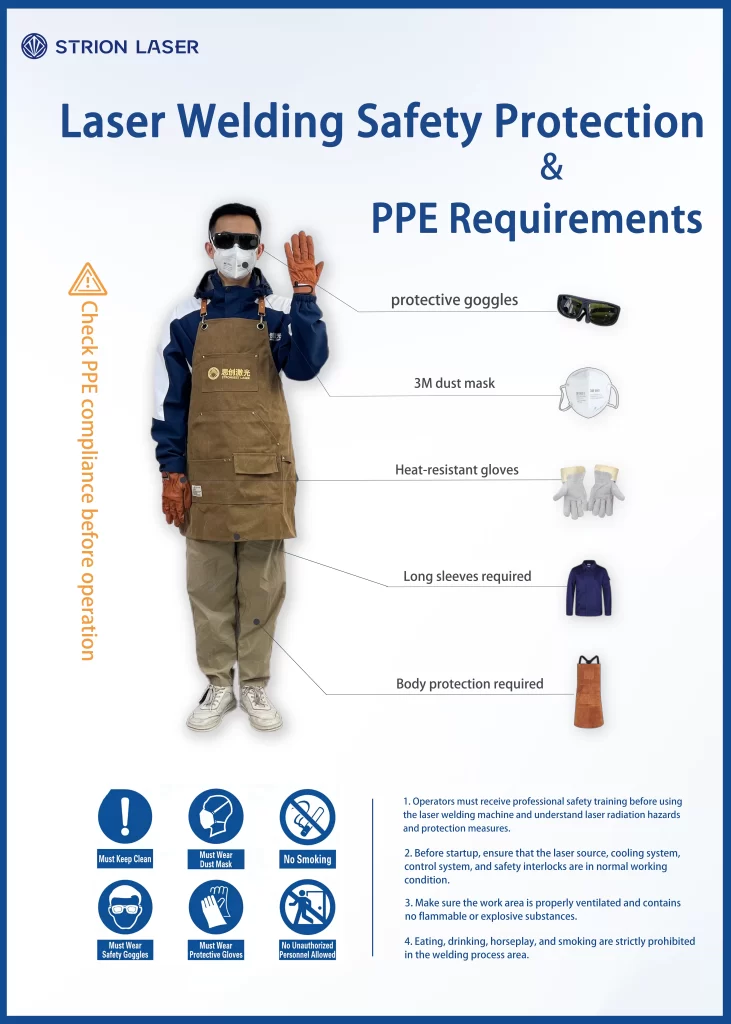

3. Personal Protective Equipment (PPE): Standardized Protective Gear for Operators

Laser radiation, welding spatter, and high temperatures are major safety hazards during handheld laser welding. Operators must wear appropriate personal protective equipment (PPE) in strict accordance with safety regulations:

- Laser safety goggles

Select laser protective eyewear with the appropriate protection rating based on the laser wavelength and power of the equipment. Proper goggles effectively block laser radiation and prevent eye injuries. - Protective clothing

Wear flame-resistant protective clothing, including gloves and safety footwear, to protect against welding sparks and contact with high-temperature workpieces. - Respiratory protection

When welding materials that generate hazardous fumes, such as galvanized steel, operators should wear professional respirators or gas masks to filter toxic and harmful gases.

Operational Safety: Strict Adherence to Proper Operating Procedures

During handheld laser welding, operators must remain fully focused and strictly follow approved operating procedures to prevent safety incidents caused by improper operation.

1. Proper Equipment Operation: Mastering Professional Skills

Before starting welding operations, operators must become fully familiar with all functions of STRION LASER equipment, including welding modes (spot welding / continuous spot welding), parameter settings, and wire feeding speed (25–150 cm/min). Based on the material type and thickness of the workpiece, operators should select the appropriate process package (STRION LASER systems offer 20+ built-in welding process packages) and parameters to avoid equipment malfunction or welding accidents caused by improper settings.

- Correct handling of the welding torch

The STRION LASER K Series welding torch weighs only 390 g and features an ergonomic grip design. Operators should maintain a stable posture during operation and keep a safe distance from the torch, ensuring the laser output aperture is never directed toward themselves or others. - Continuous monitoring during welding

Operators must closely observe the welding area at all times. If abnormal conditions occur—such as unstable laser output, excessive spatter, or unusual odors—immediately press the emergency stop button, shut down the machine, and disconnect the power supply. Do not resume operation until the equipment has cooled down and the issue has been fully resolved. - Safe adjustments and wire replacement

When replacing welding wire or adjusting the workpiece, always switch off the laser output and power supply to prevent accidental laser activation.

2. Handling Special Situations: Stay Calm and Respond Properly

- Fire caused by welding sparks

If a fire is triggered by welding spatter, immediately stop welding, cut off the power supply, and use the prepared firefighting equipment to extinguish the fire. If the fire cannot be controlled quickly, call the local fire emergency number and evacuate to a safe area without delay. - Accidental laser radiation exposure

In the event of unintended laser exposure, stop operation immediately and leave the work area. Seek medical attention as soon as possible. Do not rub the eyes or skin, as this may worsen the injury. - Welding large or complex workpieces

When welding large components or complex structures, assign a dedicated safety observer to monitor the surrounding area. This helps prevent welding sparks from reaching flammable materials and reduces the risk of accidental injury to others.

Post-Operation Safety: Do a Good Job in Shutdown and Maintenance

After the welding work is completed, operators should not leave the workplace immediately. They need to do a good job in equipment shutdown, workplace cleaning, and maintenance to ensure the safety of the next operation:

1. Standard Shutdown Procedure: Protecting Equipment and Eliminating Potential Hazards

First, turn off the laser output, then shut down the wire feeder (STRION LASER–compatible models such as STR-WFS-A and STR-WFD-A), and finally disconnect the main power supply.

After shutdown, allow the cooling system to stop completely—typically 5–10 minutes—to ensure the machine is fully cooled. This prevents internal component damage caused by sudden power-off and enhances long-term equipment reliability.

2. Cleaning and Maintenance: Extending Equipment Life and Ensuring Safety

- Timely cleaning of the welding torch

Use dedicated cleaning tools to remove spatter and dust from the torch surface. Inspect the protective window and focusing lens for wear or damage, and replace them as required according to the operation manual. STRION LASER welding torches support quick replacement of protective windows and focusing lenses, ensuring efficient maintenance. - Workspace cleanup

Collect welding residues such as wire fragments and workpiece debris and dispose of them in accordance with environmental regulations. Remove welding fumes and dust to keep the workspace clean, orderly, and safe. - Regular equipment maintenance

Perform routine maintenance as specified in the STRION LASER product manual, including checking the tightness of electrical connections, replacing cooling media, and calibrating laser output. Regular maintenance not only extends equipment service life but also ensures safe, stable, and reliable operation.

Conclusion: Safety Is the Foundation of Efficient Production

Handheld laser welding technology has brought revolutionary changes to modern manufacturing, but safety is the prerequisite for fully realizing its advantages. As a trusted partner in the field of laser welding, STRION LASER integrates safety into every aspect of product design—from the dual-loop direct refrigerant cooling system and anti-spatter welding torch to responsive safety interlock systems and comprehensive welding process packages—all designed to deliver a safer and more reliable operating experience.

Operators must always prioritize safety by strictly following pre-operation, in-process, and post-operation safety procedures, while continuously improving their professional skills and safety awareness. Only by doing so can the full performance of STRION LASER handheld laser welding machines be realized—achieving high efficiency, consistent quality, and safe production, and laying a solid foundation for long-term, sustainable growth.

For more detailed laser welding safety guidelines and product information, please visit www.strlaser-en.com or contact us at +86-28 85812068. Our team is ready to provide professional, comprehensive technical support and services.