Welding technology has evolved significantly, offering you more options than ever before. A handheld laser welding machine represents one of the most advanced solutions, delivering precision and efficiency that traditional methods often struggle to match. Industries like automotive manufacturing, aerospace, and kitchenware production increasingly rely on this innovative tool. Construction, steel manufacturing, and industrial equipment assembly also benefit from its versatility. Understanding how these methods differ helps you make informed decisions, ensuring the best results for your projects.

What is Handheld Laser Welding Machine?

How Handheld Laser Welding Machines Work

A handheld laser welding machine uses advanced laser welding technology to join metal materials with precision. The process begins with a high-energy laser beam generated by a fiber or solid-state laser. This beam focuses on a small point, creating intense heat that melts the metal. As you move the laser across the material, the molten pool solidifies, forming a strong and seamless weld.

Key components ensure the machine operates efficiently:

Semiconductor laser chip: Acts as the core of the laser, ensuring effective heat dissipation.

Heat dissipation system: Maintains the machine’s performance and longevity.

This laser welding system offers unmatched control, allowing you to achieve high-quality results with minimal distortion.

Unique Features of Handheld Laser Welding Machines

Handheld laser welding machines stand out due to their versatility and efficiency. These machines are compact and lightweight, making them easy to handle and transport. They deliver precise welds, reducing the need for post-processing.

Some unique features include:

Portability: Ideal for on-site welding tasks.

Energy efficiency: Consumes less power compared to traditional methods.

Material compatibility: Works with metals like aluminum, stainless steel, and brass.

Safety measures: Operators must wear protective gear and follow safety protocols to ensure safe operation.

These features make handheld laser welding machines a preferred choice for industries requiring precision and speed.

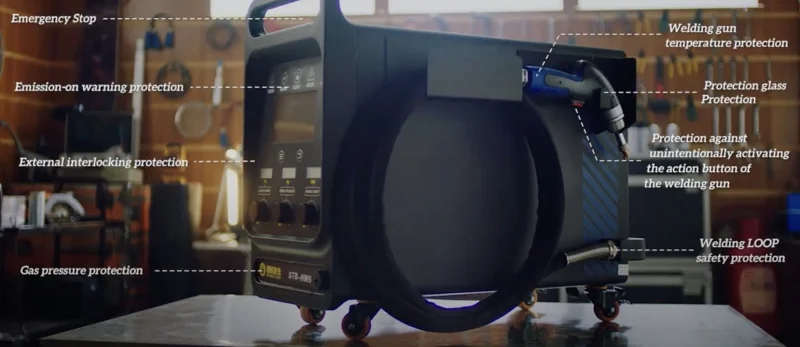

STRONGEST LASER: The STR-HW Series Handheld Laser Welding Machine

The STR-HW Series by STRONGEST LASER redefines laser welding services with its cutting-edge design. This machine uses dual-circuit refrigerant cooling, enabling continuous operation even in extreme temperatures. Its compact size and lightweight design enhance portability, making it 60% smaller than traditional water-cooled systems.

Key specifications include:

| Specification | Details |

| Max Output Power | 1500W |

| Weight | 38 KG |

| Dimensions | 675 x 310 x 580 mm |

| Cooling Method | Dual-Circuit Refrigerant Direct Cooling |

| Welding Speed | 20~80 cm/min |

| Operating Temperature | -20~60°C |

| Welding Thickness | 0.2~2.5 mm |

| Number of Preset Process Packages | 16 sets |

| Warranty | 1 Year |

The STR-HW Series also supports welding, cutting, and cleaning, making it a versatile tool for various applications. Its innovative design ensures efficient operation, reduced energy consumption, and consistent performance.

What is Traditional Welding Method?

Traditional welding methods have been the backbone of metal fabrication for centuries. These techniques involve using heat, pressure, or both to join metals. Over time, they have evolved from ancient forge welding to modern arc welding, adapting to new materials and industrial needs. Today, traditional welding techniques remain essential in industries like construction, automotive manufacturing, and shipbuilding.

Common Traditional Welding Techniques

MIG Welding (Metal Inert Gas)

MIG welding, also known as Gas Metal Arc Welding (GMAW), uses a continuous wire electrode and shielding gas to create a weld. This method is popular for its speed and ease of use, especially with thicker materials. Industries like automotive and construction rely on MIG welding for its versatility with various metals.

TIG Welding (Tungsten Inert Gas)

TIG welding, or Gas Tungsten Arc Welding (GTAW), uses a non-consumable tungsten electrode to produce precise welds. This technique is ideal for thin materials and applications requiring high-quality results, such as aerospace and automotive manufacturing. TIG welding delivers clean welds with minimal defects, making it a preferred choice for projects demanding structural integrity.

SMAW (Shielded Metal Arc Welding)

SMAW, commonly called stick welding, uses a consumable electrode coated in flux to create an arc. This method is highly portable and effective for outdoor repairs and construction projects. Its simplicity and versatility make it a go-to option for many welders.

How Traditional Welding Methods Work

Traditional welding methods operate by generating intense heat to melt and fuse metals. Techniques like arc welding use an electric arc, while gas welding relies on a flame created by fuel gas and oxygen. Once the molten pool cools, it solidifies into a strong joint. These methods often require skilled operators to ensure precision and quality.

Key Features of Traditional Welding Methods

Versatility: Suitable for various applications, from automotive repairs to shipbuilding.

Material Compatibility: Works well with metals like steel, aluminum, and iron.

Portability: Techniques like stick welding require minimal equipment, making them ideal for on-site tasks.

Cost-Effectiveness: Equipment for traditional welding is generally more affordable than advanced alternatives.

Safety Considerations: Operators must follow strict safety protocols to avoid risks like UV burns, toxic fumes, and electric shock.

Traditional welding techniques remain indispensable despite advancements in welding technology. Their adaptability and reliability make them a cornerstone of metalworking industries.

Detailed Comparison: Handheld Laser Welding vs Traditional Welding

Cost

When comparing costs, handheld laser welding machines require a higher initial investment. The advanced technology and precision of these machines make them more expensive upfront. Additionally, servicing and maintenance fees for laser welding equipment are higher than those for traditional welding methods. This can be a significant consideration for small-scale projects or businesses with limited budgets.

On the other hand, traditional welding methods are more cost-effective for small and medium businesses. The equipment for techniques like MIG or stick welding is generally more affordable. Maintenance costs are also lower, making traditional welding methods accessible to a wider range of users. However, in the long term, handheld laser welding machines can offset their high initial cost. Their efficiency, reduced energy consumption, and minimal post-processing requirements lead to lower operational expenses. Improved weld strength and reduced material waste further enhance profitability over time.

Efficiency and Speed

Handheld laser welding machines excel in welding efficiency and speed. These machines achieve faster processing times due to their high-energy laser beams. Welding speeds range from 40 to 400 inches per minute, making laser welding 4 to 10 times faster than many traditional welding methods. This speed is ideal for high-volume production, significantly reducing project timelines.

Traditional welding methods, while effective, often require more time to complete tasks. Techniques like TIG welding demand a high level of skill and precision, which can slow down the process. In contrast, laser welding offers faster heating and cooling rates, making it more efficient for small-scale tasks. The precision of laser welding also reduces the need for skilled labor, further enhancing productivity.

Heat Input and Material Distortion

Heat input plays a crucial role in determining the quality of a weld. Handheld laser welding uses minimal and controlled heat, which reduces the risk of damage to surrounding materials. The concentrated laser beam creates a smaller heat-affected zone (HAZ), minimizing thermal distortion. This makes laser welding suitable for delicate or thin metals, where traditional methods might cause warping or deformation.

Traditional welding methods, such as MIG welding, often produce a larger HAZ due to higher heat input. This can alter the microstructure of metals, leading to material distortion. While traditional methods remain effective for many applications, they may not be the best choice for projects requiring high precision or working with sensitive materials. Laser welding’s ability to minimize thermal damage ensures superior welding efficiency and quality.

Precision and Control in Welds

Achieving precision and control in welds is essential for high-quality results. Handheld laser welding machines excel in this area, offering unmatched accuracy compared to traditional methods. These machines use a focused laser beam to create narrow seam widths, ensuring uniform and consistent welds. You can achieve precise results even on delicate materials like thin metals, as the laser minimizes deformation by generating a smaller heat-affected zone (HAZ).

Traditional welding methods, while effective, often struggle with maintaining uniformity. The dispersed heat source can lead to defects such as cracks or slag inclusions. Skilled operators can improve the accuracy of traditional welds, but the level of control still falls short of what laser welding provides. With handheld laser welders, you gain the ability to focus on spot sizes as small as 50 microns, making them ideal for intricate applications in industries like aerospace and electronics.

The high energy density of laser welding ensures localized heating, reducing the risk of material damage. This precision allows you to work on a variety of materials without compromising their structural integrity. Whether you’re welding thin metals or creating strong joints in complex assemblies, handheld laser welding machines offer superior control and reliability.

Material Compatibility

Handheld laser welding machines are compatible with a wide range of materials, making them versatile tools for various industries. You can weld metals like carbon steel, stainless steel, aluminum, and copper with ease. These machines also excel in joining dissimilar metals, which is challenging for traditional methods. For example, laser welding can handle materials up to 4 mm thick for carbon and stainless steel, and up to 2 mm for copper.

Traditional welding methods often face limitations when working with certain materials. High heat levels can cause thermal distortion, especially in thin metals, leading to warping or burn-through. Laser welding overcomes these challenges by using concentrated heat, preserving the material’s properties and ensuring clean, precise welds. This capability makes laser welding suitable for applications requiring high precision, such as kitchen cabinets, auto parts, and staircase elevators.

Applications and Use Cases

Handheld laser welding machines find applications across a wide range of industries due to their precision and versatility. In the automotive sector, you can use them to weld small components, repair cracks, and connect complex metal parts. The aerospace industry benefits from their ability to assemble lightweight materials and repair turbine blades.

In jewelry making, laser welding allows you to repair broken chains and resize rings without the need for extensive polishing. The electronics industry relies on these machines for joining sensitive elements like connectors and circuit boards. Medical device manufacturers use laser welding to produce and repair surgical instruments with hygienic welds.

Traditional welding methods remain indispensable for large-scale projects. You can use them to fabricate steel frameworks for skyscrapers, assemble vehicle frames, and join pipes in the oil and gas industry. While traditional methods are effective for heavy-duty tasks, handheld laser welding machines offer a modern solution for precision-focused applications.

Pros and Cons of Each Method

Pros and Cons of Handheld Laser Welding Machines

Handheld laser welding machines offer several advantages that make them a preferred choice for modern welding tasks.

These machines are lightweight and portable, allowing you to move them easily between locations. Their compact design makes them ideal for welding in tight spaces or on intricate components.

The intuitive controls simplify operation, making them accessible to both beginners and professionals. You can quickly adjust settings to suit different welding tasks.

Handheld laser welders deliver precise results with minimal distortion. This precision reduces the need for post-processing, saving you time and effort.

Their versatility allows you to work with a wide range of materials, including aluminum, stainless steel, and brass.

However, these machines come with certain drawbacks.

| Disadvantage | Description |

| High Initial Cost | The high upfront cost of these machines is their primary drawback, making them costlier than traditional welding equipment. |

| Maintenance and Repairs | These machines require routine maintenance for optimal performance, and repairs can be expensive, affecting productivity during downtime. |

Despite these challenges, the efficiency and precision of handheld laser welding machines often outweigh their limitations, especially for industries requiring high-quality welds.

Pros and Cons of Traditional Welding Methods

Traditional welding methods remain essential for many applications due to their reliability and cost-effectiveness.

These methods are versatile, allowing you to work with various metals like steel, aluminum, and iron.

The equipment is generally more affordable, making it accessible for small-scale projects or businesses with limited budgets.

Techniques like stick welding are portable and suitable for on-site tasks.

However, traditional welding methods have notable limitations.

Higher heat inputs can cause greater distortion and residual stresses in the materials.

Precision and control over weld geometry and penetration depth are lower compared to laser welding.

Skilled operators are often required to achieve consistent results, which can increase labor costs.

While traditional welding methods are effective for heavy-duty tasks, they may not meet the precision and efficiency demands of modern industries.

Conclusion

Choosing between handheld laser welding machines and traditional welding methods depends on your specific needs. Handheld laser welders offer unmatched precision, portability, and speed, making them ideal for intricate tasks and thin materials. Traditional methods, however, excel in affordability and heavy-duty applications.