900W vs 1200W vs 1500W vs 2000W vs 3000W Handheld Laser Welder: How to Choose?

Handheld laser welding machines have become a key solution in modern manufacturing, offering high efficiency, flexibility, and precision for small workshops, mid-sized factories, and industrial production lines.

With power options ranging from 900W to 3000W, choosing the right model can be challenging. Which power level best fits your actual production needs?

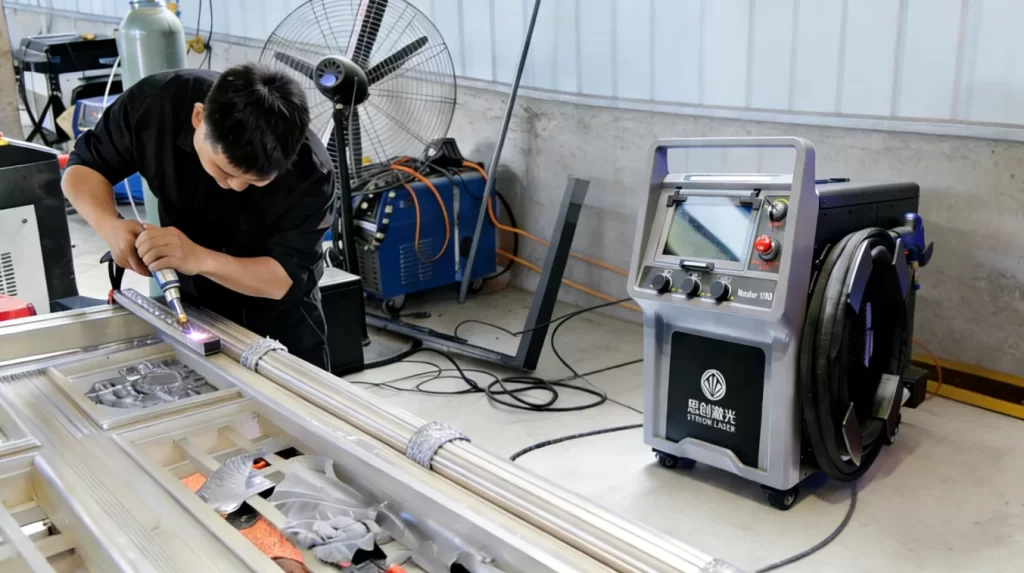

STRION LASER offers the MASTER X Series and LITE S Series handheld laser welders, covering all mainstream power levels. Each model is designed for specific materials, thicknesses, and applications, helping users achieve optimal welding performance with maximum cost efficiency.

Core Selection Logic: Power Defines Capability, Application Defines the Choice

Before selecting the power level of a handheld laser welder, two key questions must be clearly defined: What materials do you usually weld, and what is the maximum material thickness? Laser power directly determines weld penetration depth, welding speed, and material compatibility.

STRION LASER’s product lineup is engineered around these practical requirements. Each power level is precisely positioned to serve specific applications and production scenarios.

Below is an overview of the core welding capabilities of STRION LASER handheld laser welders at different power levels (based on official product testing and compared with conventional welding processes):

| Power Level | Corresponding Model | Aluminum | Stainless Steel | Galvanized Sheet | Carbon Steel |

| 900W | LITE S30 | 3mm | 3mm | 2mm | 3mm |

| 1200W | LITE S40 | 4mm | 4mm | 3mm | 4mm |

| 1500W | MASTER X50 | 5mm | 5mm | 4mm | 5mm |

| 2000W | MASTER X60 | 6mm | 6mm | 5mm | 6mm |

| 3000W | MASTER X80 | 7mm | 8mm | 7mm | 10mm |

It is clear that as laser power increases, the achievable welding thickness for various materials rises significantly. However, higher power does not automatically mean a better choice. Matching the power level to real production requirements is the key to avoiding overinvestment or insufficient capacity.

Power Model Breakdown: Clear Choices Through Real Scenarios

1. 900W (LITE S30): A Cost-Effective Entry-Level Solution for Small Workshops

The STRION LASER LITE S30 is a 900W handheld laser welder designed as an ideal entry-level solution for small workshops and independent fabricators. It is optimized for thin-sheet welding, with a maximum welding thickness of 3 mm for aluminum, stainless steel, and carbon steel, and 2 mm for galvanized steel.

Real-world case:

A small hardware workshop in Guangdong specializes in door hinges, furniture handles, and other thin metal components. Previously relying on TIG welding, the workshop struggled with slow welding speeds, inconsistent seams, and extensive post-weld polishing. Two additional workers were required solely for finishing, and the scrap rate reached 8%.

After switching to the STRION LASER LITE S30 (900W), these issues were largely eliminated. With over 20 built-in welding process presets, new operators were able to start welding confidently within half a day. Welding speed increased by three times, seams became smooth and spatter-free, and post-polishing was no longer necessary. The scrap rate dropped to below 1%, saving nearly RMB 50,000 per year in labor and material costs.

Typical applications:

The LITE S30 is well suited for small metal hardware, thin stainless steel consumer products (such as compact kitchenware and decorative parts), and light automotive components.

From an operating cost perspective, the machine has a rated input power of only 3000W, making it energy-efficient and economical for workshops with limited budgets. Weighing just 39 kg and measuring 748 × 412 × 624 mm, its compact, mobile design makes it especially suitable for facilities with limited floor space.

2. 1200W (LITE S40): The Ideal Choice for Small to Mid-Sized Workshops

The 1200W LITE S40 is one of the most versatile models in the STRION LASER lineup and a clear upgrade over the 900W version. Its welding capacity is significantly improved, supporting up to 4 mm for aluminum, stainless steel, and carbon steel, and 3 mm for galvanized steel. This makes it well suited for workshops handling more diverse materials and slightly thicker workpieces.

Real-world case:

A stainless steel water tank and sanitary product manufacturer in Zhejiang primarily works with 2–4 mm stainless steel sheets. Previously using a 900W welder, the company struggled with low efficiency when welding 4 mm material, often requiring multiple passes. After upgrading to the STRION LASER LITE S40 (1200W), the issue was fully resolved. The machine completes 4 mm stainless steel welds in a single pass, achieving welding speeds of up to 150 cm/min, nearly twice as fast as before.

3. 1500W (MASTER X50): A Reliable Solution for Medium-Thickness Welding

The 1500W MASTER X50 is designed for medium-thickness workpieces. It supports maximum welding thicknesses of 5 mm for aluminum, stainless steel, and carbon steel, and 4 mm for galvanized steel. This makes it an ideal choice for mid-sized manufacturers and professional workshops that frequently handle heavier components.

Real-world case:

A farm machinery parts manufacturer in Shandong produces tractor brackets and harvester structural components, typically 3–5 mm thick. With conventional welding methods, the company faced excessive deformation and inconsistent weld strength, leading to frequent customer complaints. After adopting the STRION LASER MASTER X50 (1500W), welding quality improved dramatically. Stable laser output with long-term power fluctuation below 1% ensured consistent penetration, reducing part deformation by 90%.

The integrated 10 m armored cable allows operators to weld large structures without repositioning the workpiece, boosting operational efficiency by 40%. In addition, the IP5X dustproof and IPX3 waterproof design enables reliable operation in dusty workshop environments, with almost zero failures reported after one year of use.

Featuring an independent drive module and photoelectric separation design for improved heat dissipation, the 1500W MASTER X50 delivers a stable and efficient welding solution for businesses requiring higher productivity and larger workpiece capability.

4. 2000W (MASTER X60): A Professional Choice for High-Intensity Welding

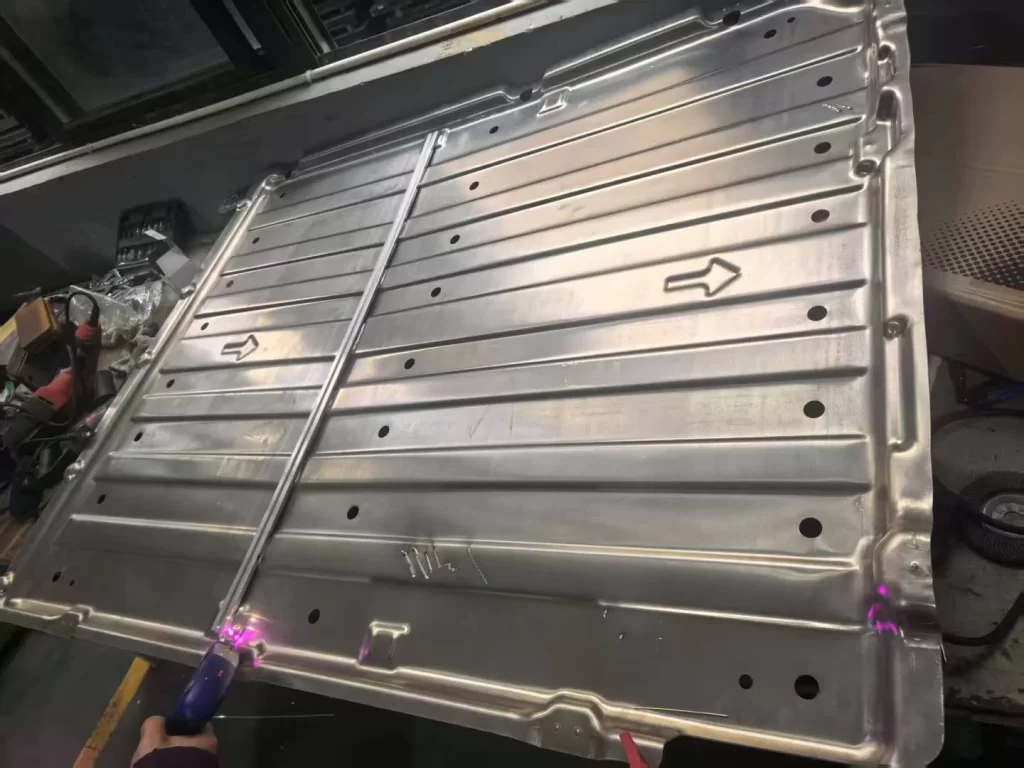

The 2000W MASTER X60 is a professional-grade handheld laser welder from STRION LASER, offering a significant step up in welding capability. It supports maximum welding thicknesses of 6 mm for aluminum, stainless steel, and carbon steel, and up to 5 mm for galvanized steel.

This model is designed for professional fabrication shops, large workshops, and industrial production lines where both thickness capacity and welding precision are critical. With higher laser power and stable output, the MASTER X60 delivers deeper penetration, faster welding speeds, and consistent weld quality, making it well suited for continuous, high-intensity production environments.

5. 3000W (MASTER X80): The Top-Tier Solution for Ultra-Thick Workpieces

The 3000W MASTER X80 is the flagship model in the STRION LASER handheld laser welding lineup, delivering the strongest welding capability in the series. It supports maximum welding thicknesses of 7 mm for aluminum, 8 mm for stainless steel, 7 mm for galvanized steel, and up to 10 mm for carbon steel.

The MASTER X80 features a rated input power of 10,500 W and is equipped with a high-performance dual-circuit refrigerant direct-cooling system, ensuring continuous and stable operation even during ultra-thick workpiece welding.For enterprises that routinely handle heavy-gauge materials and seek multi-functional integration in a single platform, the 3000W MASTER X80 stands out as an ideal solution for enhancing productivity and strengthening long-term competitiveness.

Four Key Selection Tips to Avoid Mistakes

- Prioritize workpiece thickness and materials: This is the most fundamental factor. If you mainly process thin plates below 3mm, the 900W model is sufficient; if you often deal with 3-5mm workpieces, the 1200W or 1500W model is more suitable; for workpieces above 6mm, you need to choose the 2000W or 3000W model.

- Consider future business expansion: If your workshop plans to expand its business scope and undertake thicker workpiece processing orders, it is recommended to choose a model with slightly higher power to avoid secondary investment. For example, if you currently process 3mm workpieces but may involve 5mm workpieces in the future, the 1500W model is a more forward-looking choice.

- Match with power supply conditions: The LITE S30 and S40 adopt single-phase 220V power supply, which is suitable for small workshops without three-phase power supply; the MASTER X series (1500W, 2000W, 3000W) uses three-phase 380V power supply, so you need to confirm whether the workshop’s power supply conditions meet the requirements before purchasing.

- Balance cost and efficiency: Higher power models have better performance but higher prices and energy consumption. Small workshops with limited budgets should not blindly pursue high power; instead, they should choose cost-effective models that can meet their current production needs. For enterprises with large output and high efficiency requirements, investing in high-power models can bring higher returns.

Conclusion: Choose the Right Power, Create Real Value

Selecting a handheld laser welder is not about choosing the highest power, but about matching power to your actual materials, thickness, production scale, and future plans. STRION LASER’s LITE S series (900W–1200W) and MASTER X series (1500W–3000W) cover a complete power range, with each model clearly positioned for specific applications.